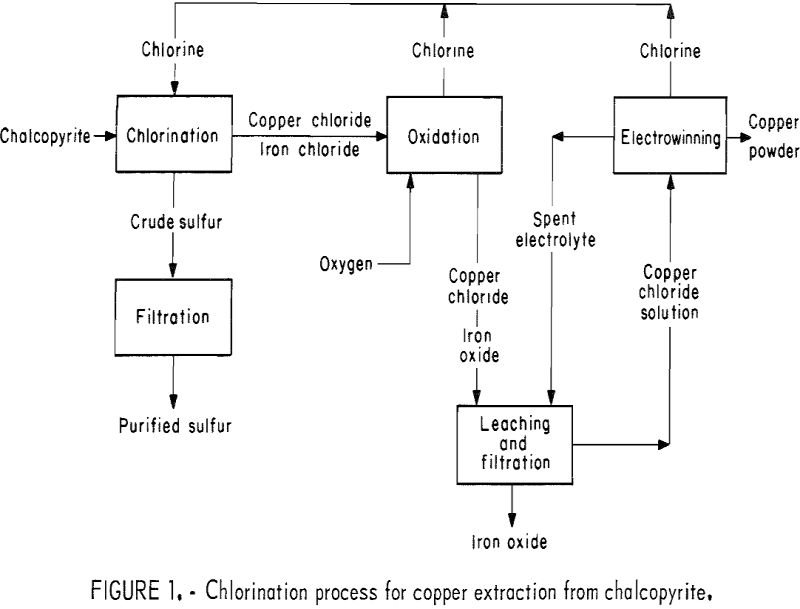

How to Chlorinate Leach Copper Chalcopyrite

The present technology for processing copper sulfide ores involves pyro-metallurgical (smelting) and to some degree hydrometallurgical techniques. Although these techniques are efficient and economical, they cause air and water pollution. Environmental concern has led the Bureau of Mines to investigate an anhydrous chlorination technique to extract Cu, Fe, and elemental S from sulfide ore without […]

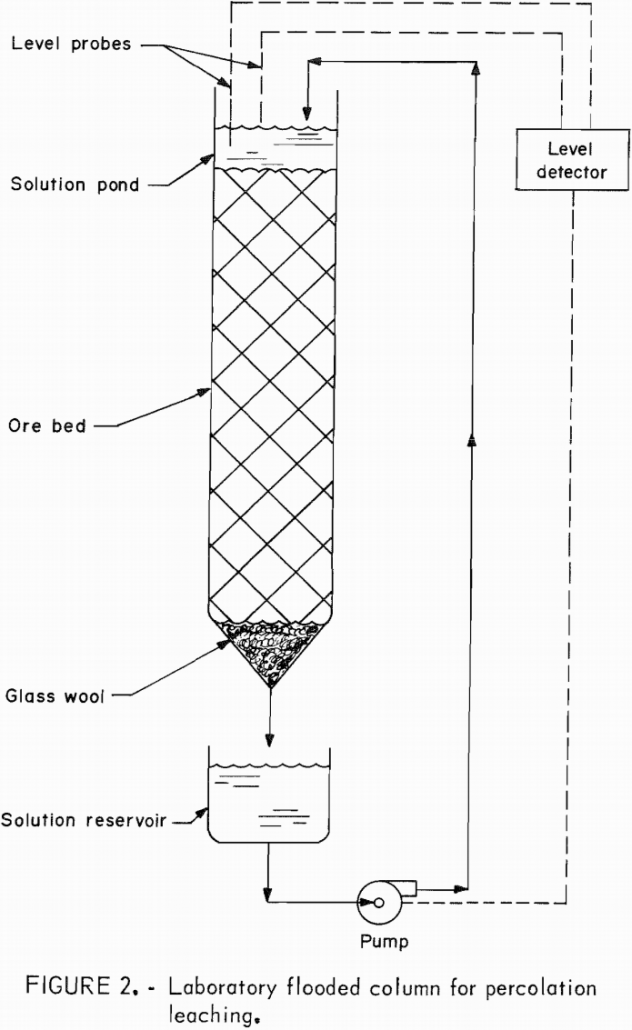

How to Extract Uranium from Granite

Despite severe slippage in the growth rate of nuclear power, current estimates still show that the U.S. uranium demand will exceed the production capacity from known resources by about 1981. Projected demands also show that a fourfold to sixfold increase in uranium production will be necessary to meet the expected 1990 requirements. Surging demand and […]

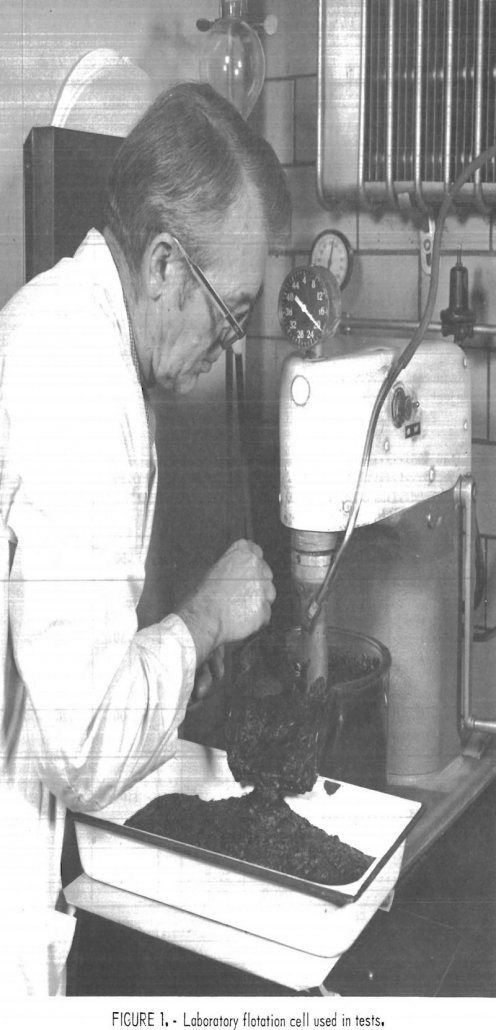

Refractory Coal Flotation

There is a wide difference in the floatability of coals of different rank, and even of the same rank, depending on whether they have been freshly mined or allowed to oxidize. Also, differences in floatability, presumably due to oxidation, may occur within a particular seam because of ground water percolating through the coal bed or […]

Copper Arsenic Smelting

Copper smelting practice has not changed much over the last century. Little attention has been paid to the gas-fired reverberatory furnace because it has traditionally represented only about 10 percent of the total cost of producing copper from its ores. However, the emphasis on air pollution control, fuel shortages, and costs have generated interest in […]

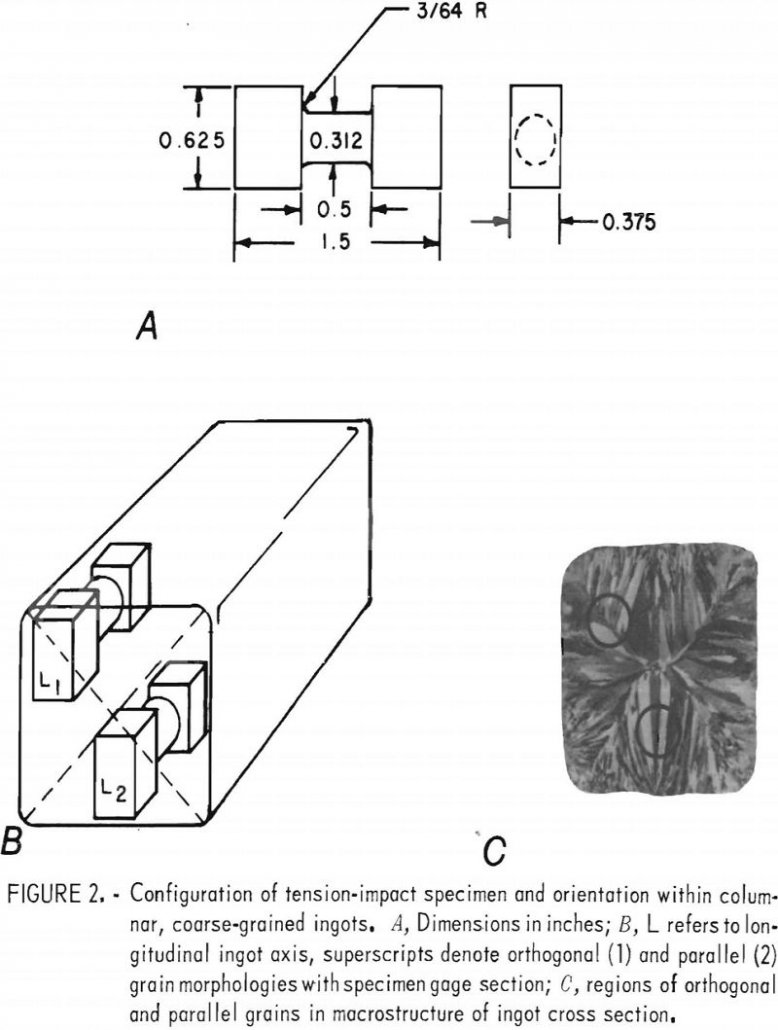

Electrowon Copper Manufacturing

One aim of metallurgy research within the Federal Bureau of Mines is the advancing of metals and minerals processing technology to foster the overall goal of maintaining an adequate supply of minerals and metals to meet national economic and strategic needs. This report describes part of a research effort aimed at increasing the utilization of […]

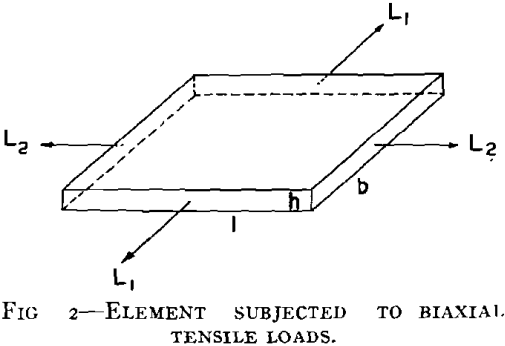

Plastic Flow Under Biaxial Tension

During the course of an investigation of the plastic flow of aluminum aircraft sheet under combined loads, several problems arose in which analyses of the conditions leading to unstable plastic flow were needed. In order to provide these analyses, and in the hope of attaining a better understanding of the general problem of unstable plastic […]

How to Reduce Zinc Sulfide with Iron

In the quest for technological improvements in the extractive metallurgy of zinc, some efforts have been made to develop a one-step pyrometallurgical process for direct reduction of zinc sulfide to metallic zinc. The earliest endeavors were those of Eulenstein in 1912 and Peterson in 1913 who both attempted to reduce zinc sulfide with iron in […]

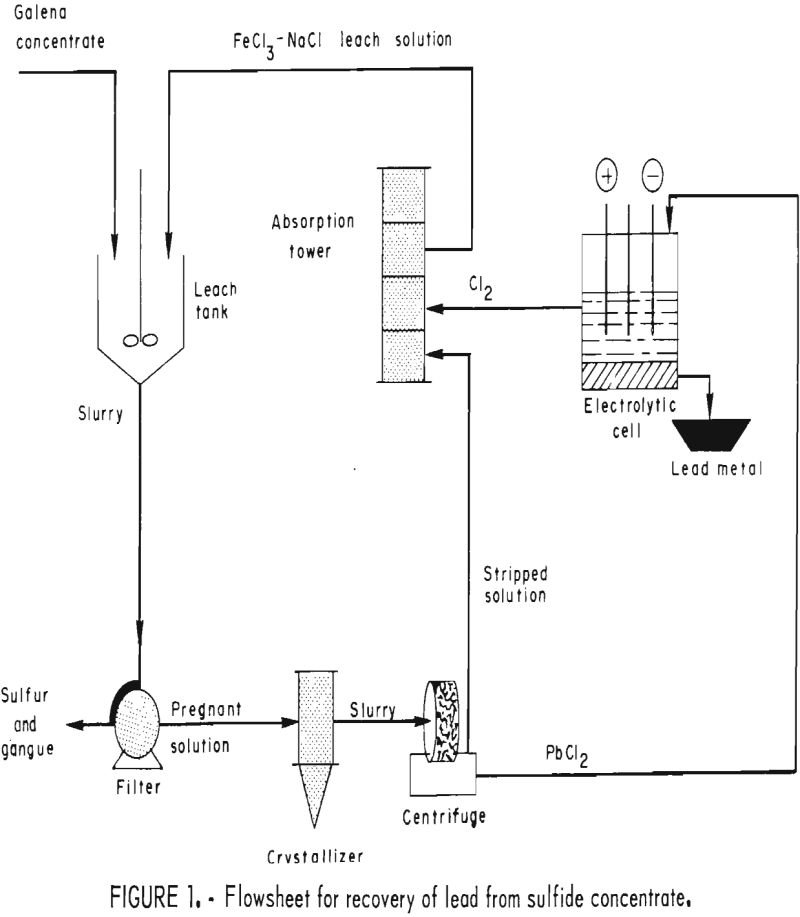

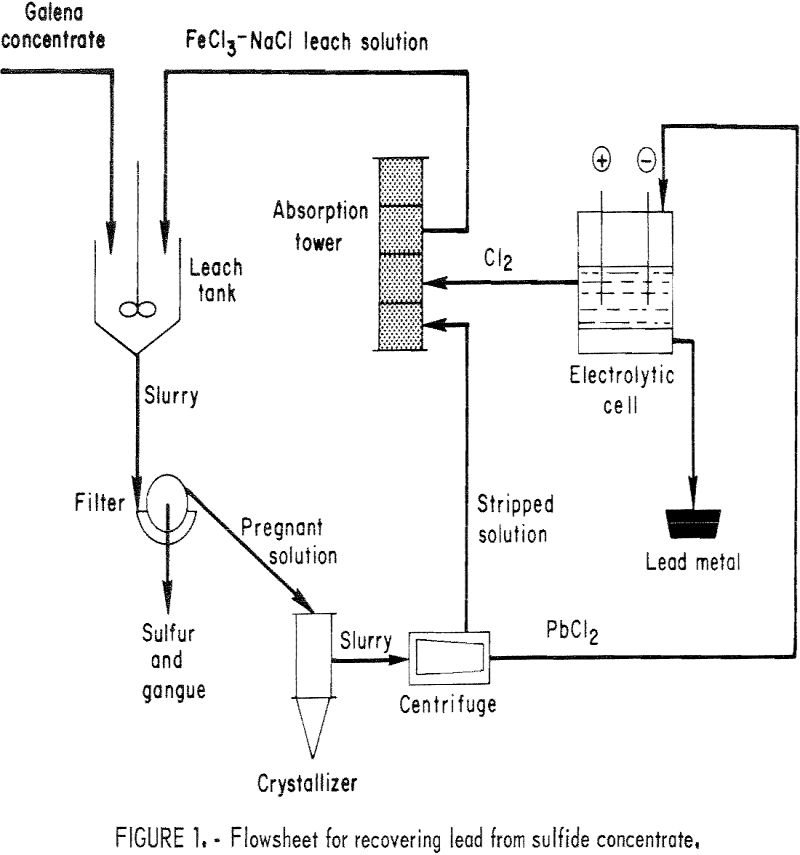

How to Recover Lead from Lead Chloride by Electrolysis

The earliest known specimen of lead, dating from 2000 B.C., is a figurine found near the Dardanelles at the site of the ancient city of Abydos. Since that time, the method for producing lead from its most abundant mineral, galena, has changed very little. Basically, a lead concentrate is mixed with fluxing agents, roasted to […]

Lead Chloride Electrolysis

During electrolysis, metal was produced from solid lead chloride in contact with the cathode rather than from lead in solution. Relatively high current densities—up to 300 amp/ft²-were possible when operating in this way. Primary lead is now usually produced from sulfide concentrate by a smelting process that involves sintering, blast furnace reduction with carbon, and […]

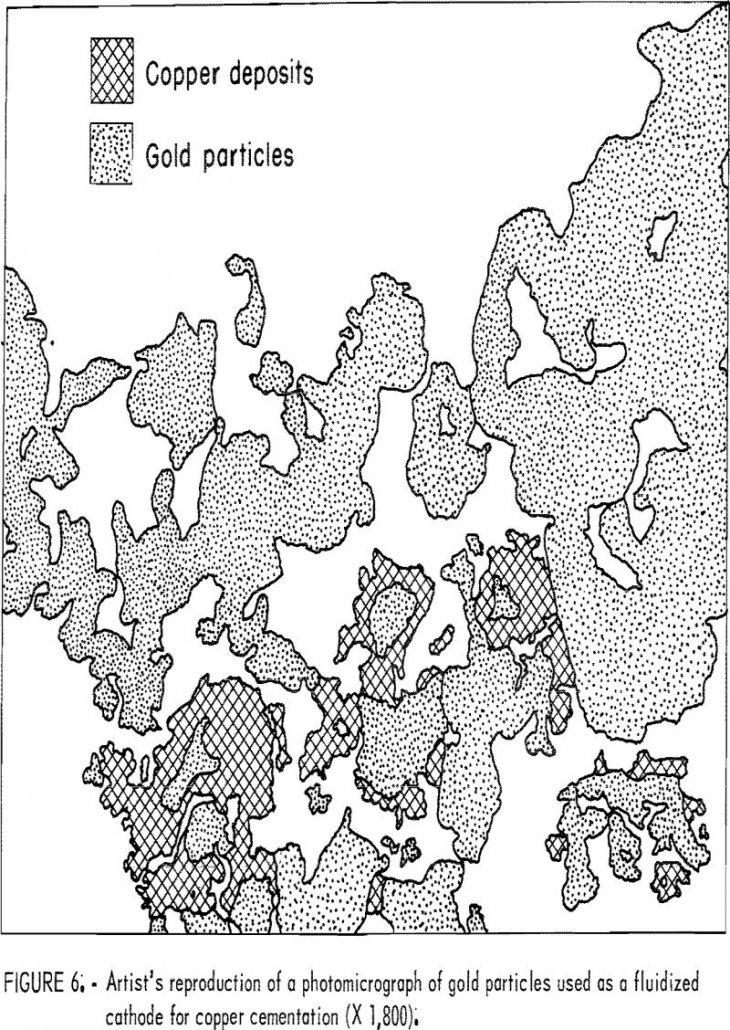

Copper Cementation Kinetics – Revolving Drum Reactor

A kinetic investigation of copper cementation on iron was made to study the effects of deposited copper on the reaction rate. Both the copper deposit attached to the iron and slurried copper particles were considered. The revolving-drum reactor used in this study allowed some of the copper to remain attached to the iron and provided […]