Carbon Fouling & Deactivation

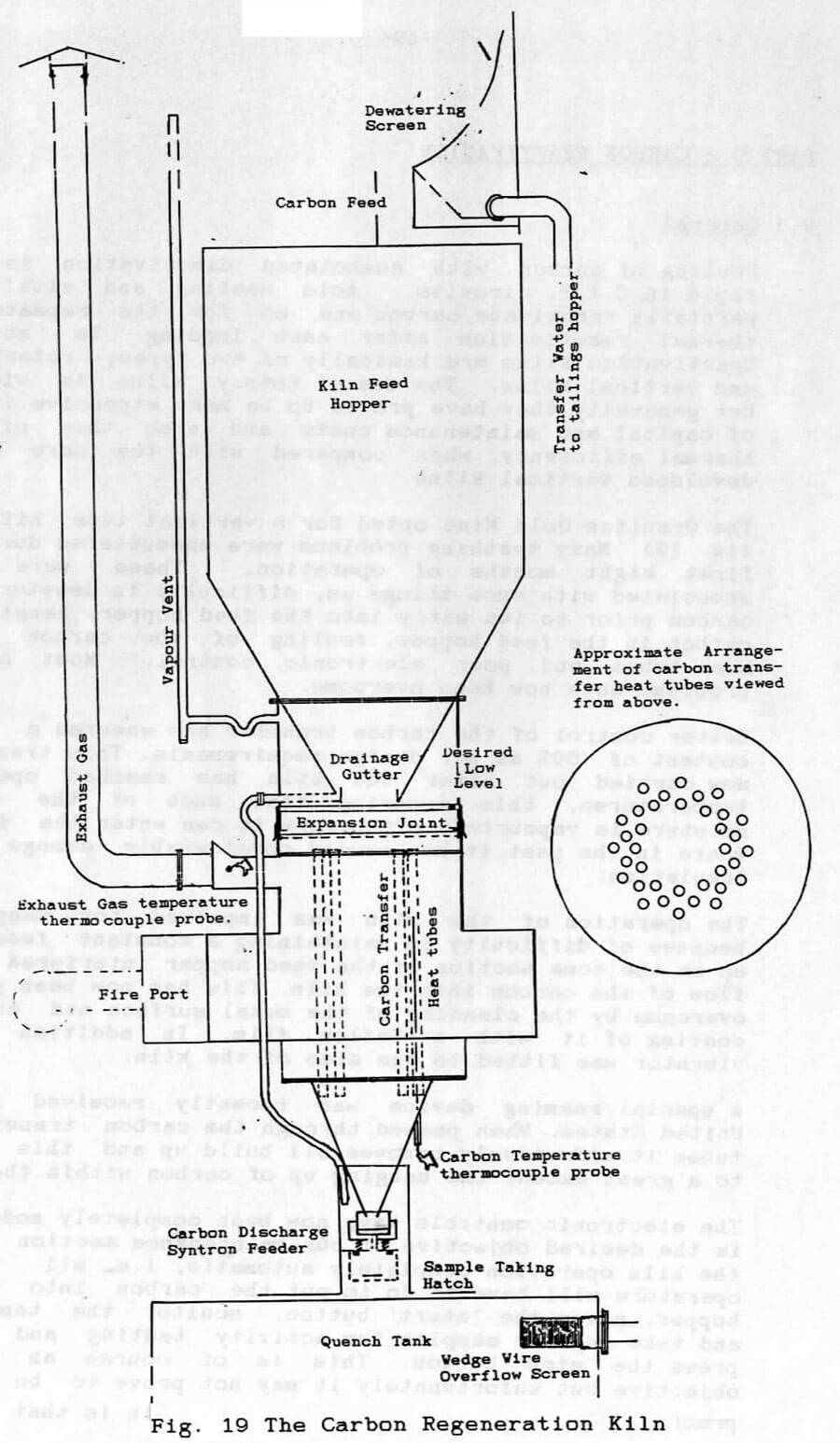

Fouling of carbon with associated deactivation is fairly rapid in CIP circuits. Acid washing and elution only partially reactivate carbon and so for its repeated use, thermal reactivation after each loading is essential. Reactivation kilns are basically of two types; rotary kilns and vertical kilns. The use of rotary kilns is widespread but generally they […]

Dry Grinding for Roasting

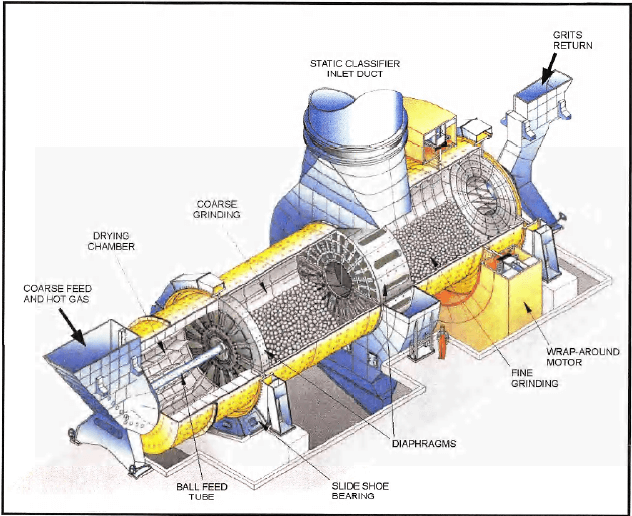

There are two parallel dry grinding circuits prior to roasting. Crushed ore is carried to the two circuits by the two reclaim conveyors located below the crushed ore stockpile. The feed rate of the crushed ore into the grinding mill is controlled by the apron feeders under the stockpile and measured by the belt scale located […]

Bond Rod Mill Work Index Equipment & Apparatus Review

Commentary on the apparatus of the Bond rod mill Work Index by Alex Doll December, 2015 alex.doll@sagmilling.com The Bond “Third Theory” of comminution was originally divided into three size classes reflecting the varieties of comminution equipment common during the time period when Bond (and his collaborators) were gathering the information to calibrate comminution models. The […]

Preparing Cathode Wool for Smelting

The cathode wool is changed weekly or more often if necessary. Electrowin day is however the cut off point. First thing on Monday morning a sample should be taken from the cell for assay and then the eluate solution diverted to the spare cell. Removing the Wool Dump the solution in the cell by opening the […]

Intensive Cyanidation

The upgrading of gravity concentrate for smelting purposes by use of intensive cyanidation is still in the experimental stage. It involves the leaching out of the gold into solution, using a strong cyanide mix, and then the electrowinning of that solution so as to recover the gold on the steel wool cathodes. This system is […]

Preparing Of Gold Gravity Concentrates For Smelting

The final concentrate taken off the Wilfley table is not suitable for direct smelting. The “lines of separation’ as shown in fig. 14 (Part 5) are not always clearly defined as there is some intrusion of impurities, namely steel, into the concentrate zone and likewise some gold finds its way into the middlings. It is […]

How to Operate a Wilfley Shaker Table

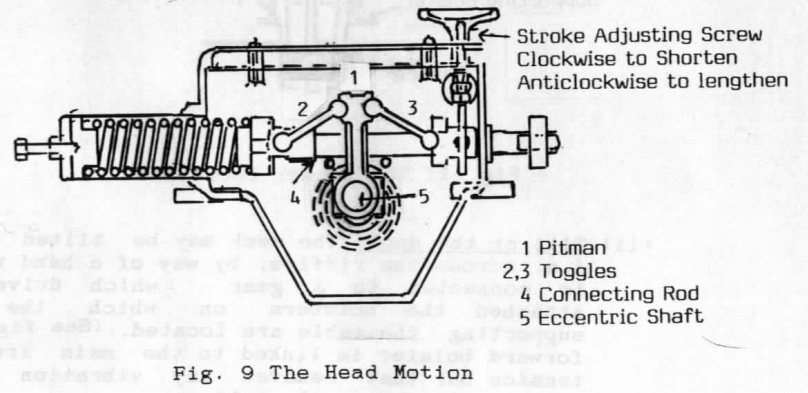

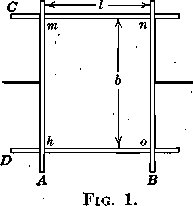

The Wilfley shaker table shown is a standard No.12 right-hand version. It is a mechanically operated reciprocating action table, consisting of a self-oiling enclosed type of head motion, a partly riffled rectangular deck, and an understructure with a tilting device for the table. Head Motion The head motion is a self-oiling Pitman and toggle type. […]

Canada: A Golden Looser

1) United States – 8,133 metric tons 2) Germany –3,381 metric tons 3) Italy –2,451 metric tons 4) France – 2,435 metric tons 5) China –1,693 metric tons 6) Russia – 1,317 metric tons 7) Switzerland – 1,040 metric tons 8) Japan – 765 metric tons 9) The Netherlands – 612 metric tons 10) India […]

Roasting Arsenic Gold Ores and Concentrates

Roasting Arsenic Gold Ore

Explaining the Process of Froth Flotation

The flotation process for the concentration of ores is a method by means of which one or more of the minerals in the ore (usually the valuable ones) are picked up by means of a liquid film and floated at the surface of a mass of fluid pulp. Here they are separated from the other […]