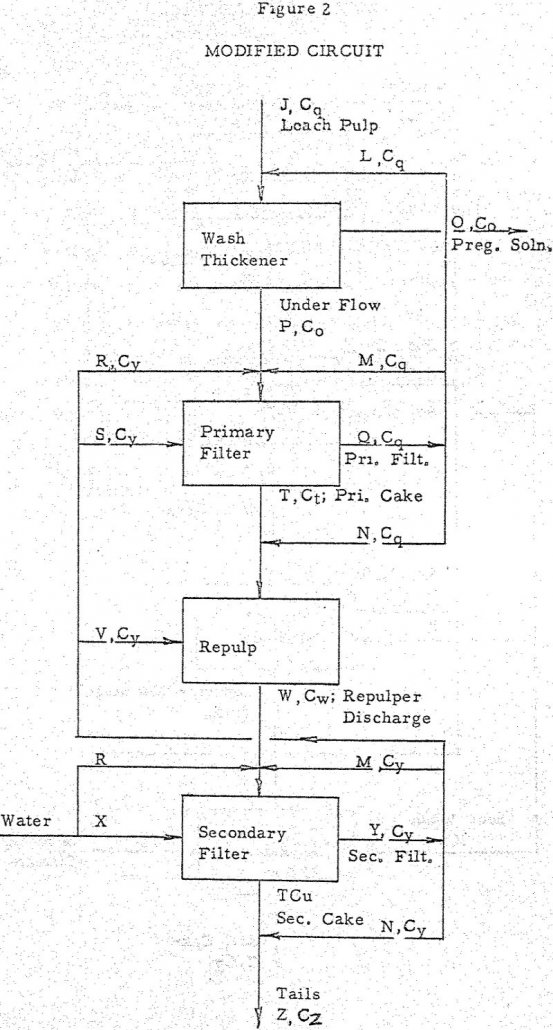

Double Stage Filtration Circuit & Wash Thickener

The operation of a series wash thickener-two stage filtration circuit determines the soluble loss in many hydrometallurgical operations. A study of this circuit yielded expressions which permit calculation of soluble loss for almost any condition of operation. The soluble loss over a range of the circuit variables is presented to illustrate and evaluate circuit performance. […]

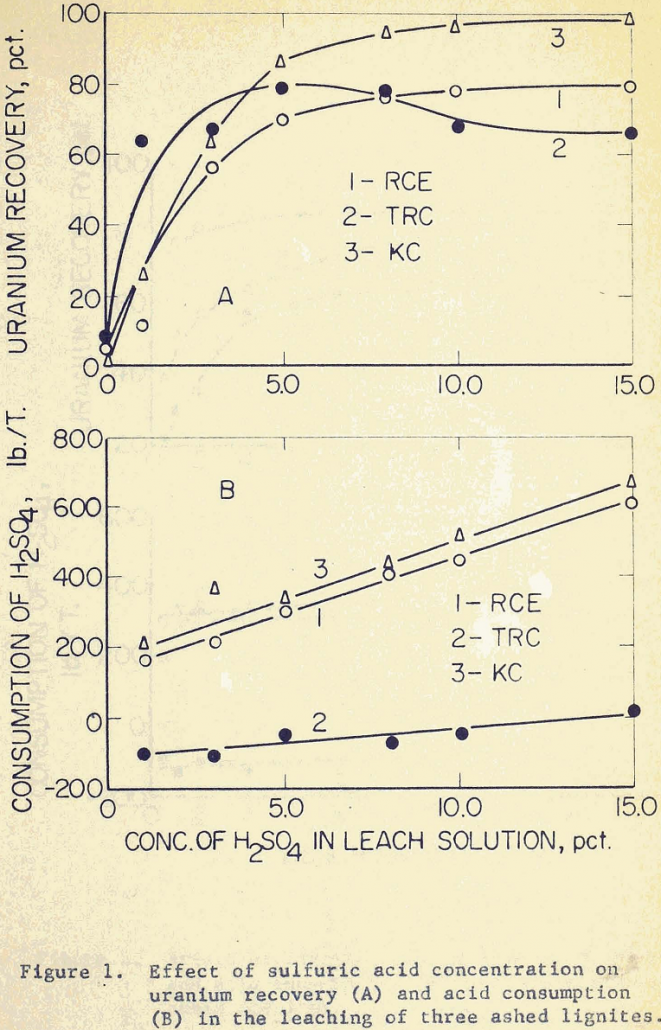

Uranium Recovery with Advanced Acid Leaching Techniques

Compared to the uranium ores in Colorado Plateau and New Mexico, the uranium-bearing lignites in North and South Dakota are relatively difficult to process. This is due chiefly to the irregular mineralization of the lignites, and partly to the non-uniform distribution of uranium within the deposits. The three lignite samples used in this investigation were […]

Bond Work Index to Measure Comminution Efficiency

Comminution efficiency can be expressed in three different ways. Theoretical Efficiency: actual energy consumed, in a comminution machine compared to the theoretical energy required to make the size reduction. Operating Efficiency: compares the operating work index, calculated from production comminution machinery operating data, to the Bond Work Index from bench scale comminution tests or calculated […]

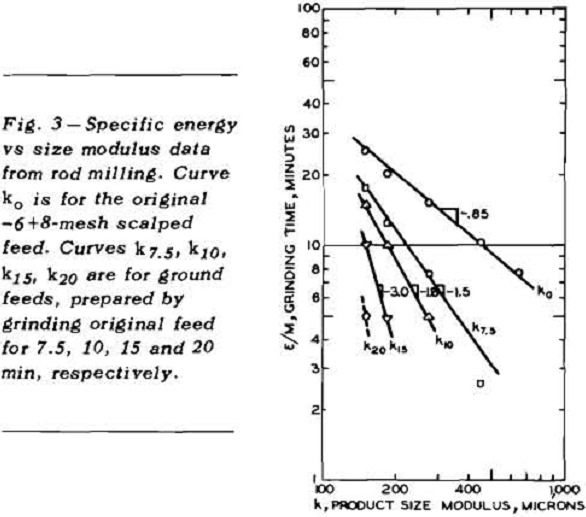

Effect of Feed Size in Comminution

The feed size cannot be neglected in any case where the effective size modulus of the feed is not too much coarser than the size modulus of the product. This can be illustrated in the second experiment of Fuerstenau and Cohen where the feed is considered to be the original -6 +8-mesh material. However, one […]

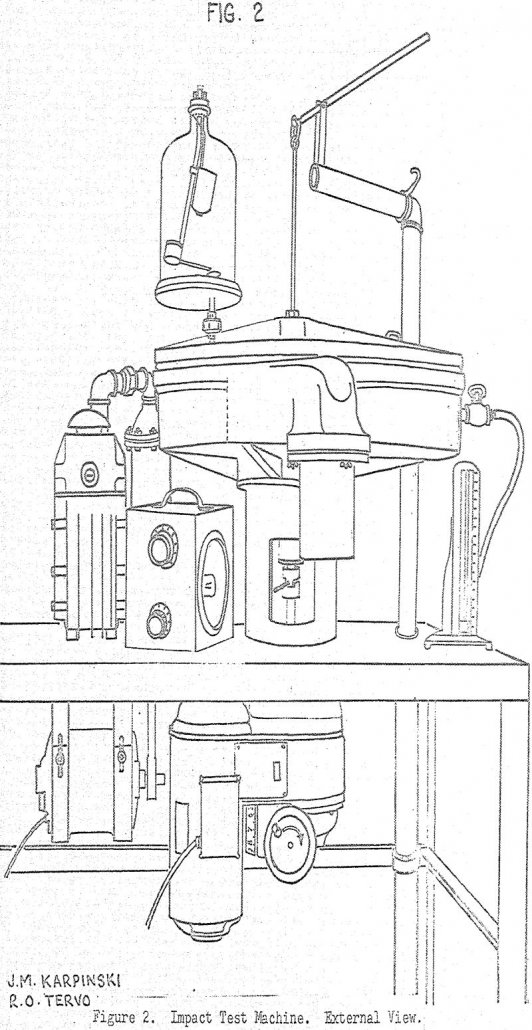

Single Impact Testing of Grains of Brittle Materials

A method and equipment have been developed for measuring the impact strength of grains of brittle materials. It is shown that brittle materials develop a characteristic particle size distribution when fractured by impact. A simple mathematical model has been found to describe this distribution, and one of the parameters of the model has been designated the […]

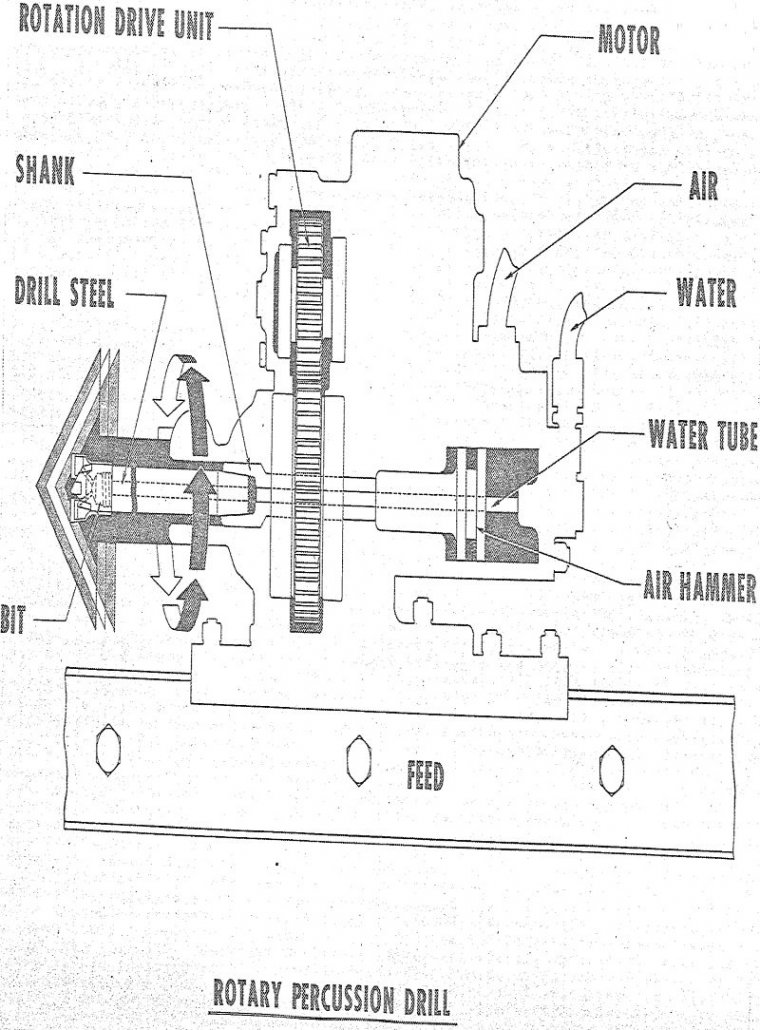

Rotary Percussion Rock Drilling

“Rotary percussion” implies two types of energy, rotary and percussion. Into these categories fall rock drills of varying sizes. The larger ones drill above 6″ diameter holes; the medium size, 2 ¾-” to 4 ½” holes; and the smallest, 1 ¼” to 2″ holes. Essentially, the larger holes are drilled with down-the-hole drills using tri-cone […]

Ropes for Drum and Koepe Friction Hoists

Four basic designs of ropes are now employed for hoisting duties: Six-strand, round strand ropes with fibre cores. Six-strand, triangular strand ropes with fibre cores. Non-rotating, multi-strand ropes. Locked coil ropes. Very solid and reliable ropes can be obtained with this simple geometric design of strand. Owing to the fact that the wires in the […]

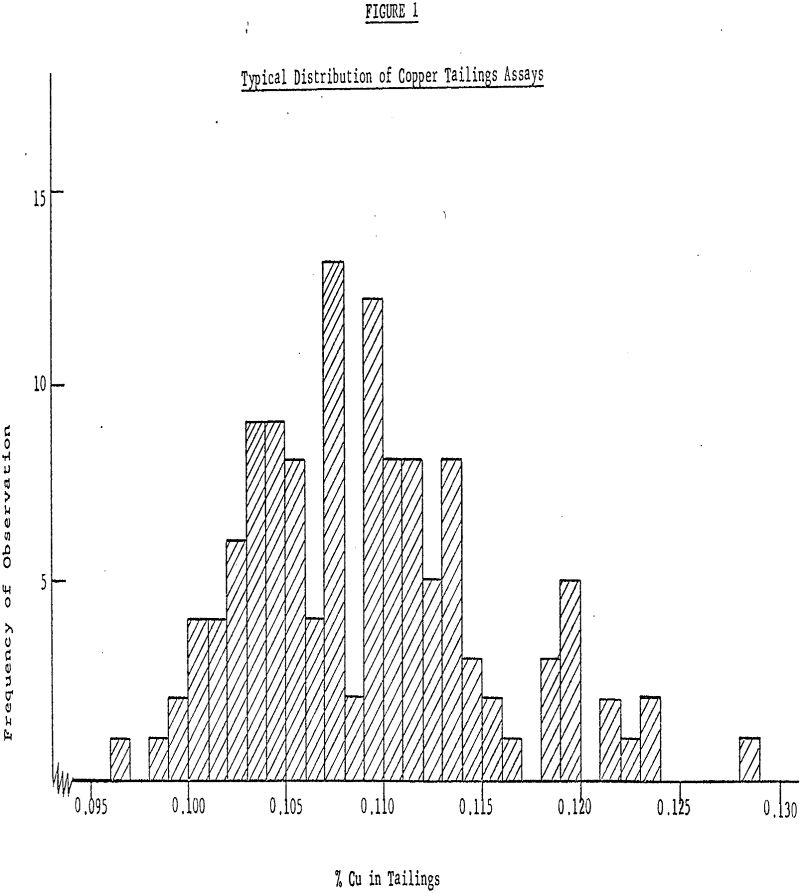

Reagent Testing – How to Analyse Results by Statistics

In the operation of today’s large scale ore-processing mills, it is extremely important to have some way of making an objective evaluation of the performance of the available flotation reagents. While Reagent Testing the use of Statistics is necessary for Result Analysis. Attempts to do this may often result in inconclusive findings since the magnitude […]

Expansible Shale Prospecting

Field criteria are needed to help the prospector recognize a potentially expansible shale, clay, or slate. Certain criteria have proven useful in California even though the physical-chemical mechanisms of expansion are not. thoroughly understood. Three conditions must be satisfied before expansion can take place. The raw material must partially fuse at a low temperature (1800-2000°F.). […]

Particle Size Reduction with Roller Mill

For reasons well known to Mining Engineers, fine grinding in the wet form is quite universal in plants engaged in the extraction of metallic values from crude ores. In the processing of non-metallic and industrial minerals, however, fine grinding in dry form is the more common method. The crude materials generally contain less moisture than […]