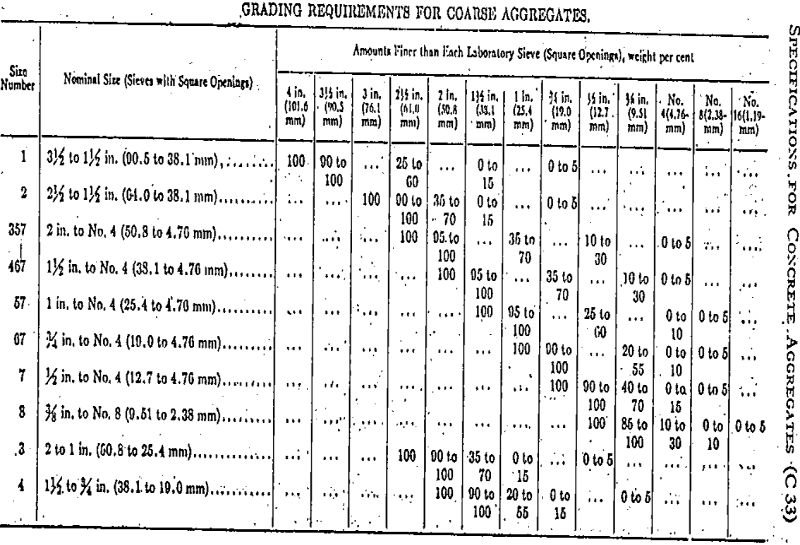

Crushing in the Aggregate Industry

In most industrialized countries, the largest element of the mining industry in physical volume is that devoted to the extraction and processing of materials for use as construction aggregates. These materials come from four main sources: (a) Excavation of unconsolidated deposits of sand and gravel (b) Stone quarrying. (c) Processing of slags and other mineral wastes. […]

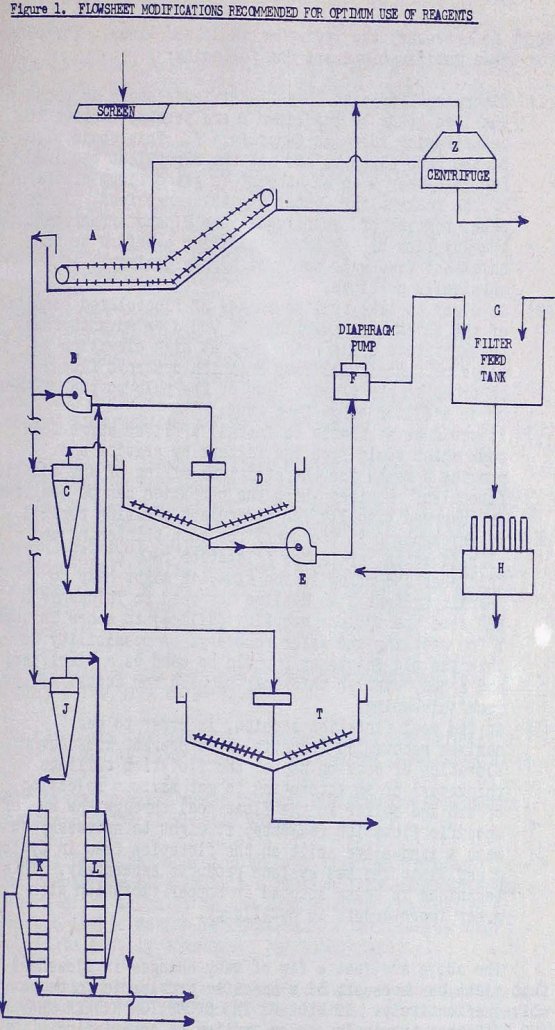

Chemical Aspects of Thickening and Clarification

Chemistry plays a more important role in milling operations than is generally recognized, particularly in fluid-solid separation processes. Chemical aspects are also very important insofar as plant water quality is concerned, and in the manner in which this water quality effects plant design and operation. One aspect of the use of mining chemicals which has […]

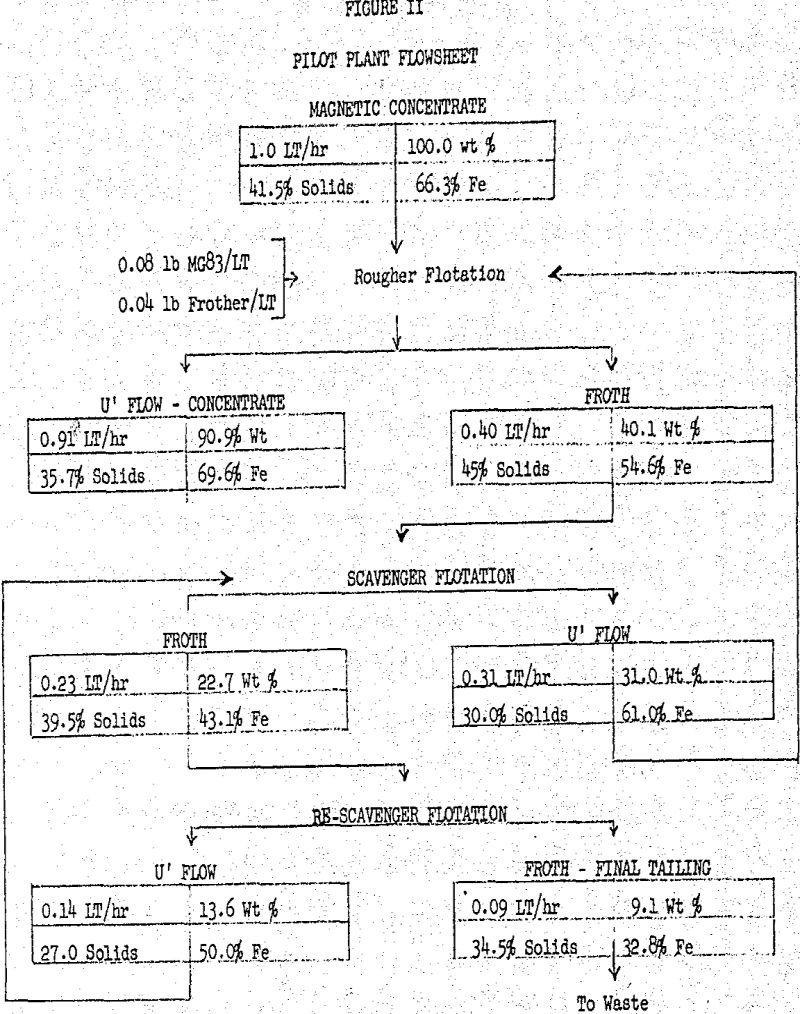

Beneficiation of Iron Concentrates by Cationic Flotation

Silica flotation with amine salts has been a commercial process for years in certain non-sulfide mineral systems. Phosphate rock and feldspar deposits are notable examples. Generally, the quartz is clean and coarse. Primary amines and imidazolines are used, usually in a mole weight range 250-300, and often fairly impure grades of collectors are satisfactory. The […]

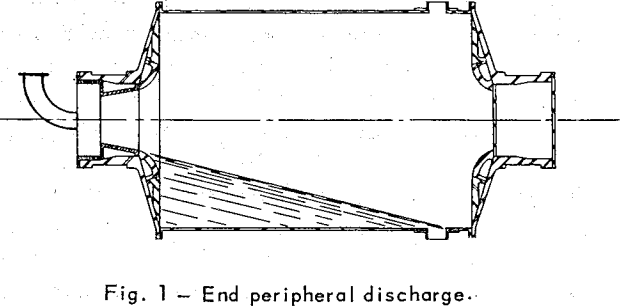

Dry Grinding Rod Mills – Dry Rod Milling

Wet grinding rod mills have been used for 50 years to grind ores and to make specification sand. The application of wet grinding rod mills is well understood. Until recently, there have been very few installations of dry grinding rod mills. The basic principles learned from wet grinding rod mills that were used in the […]

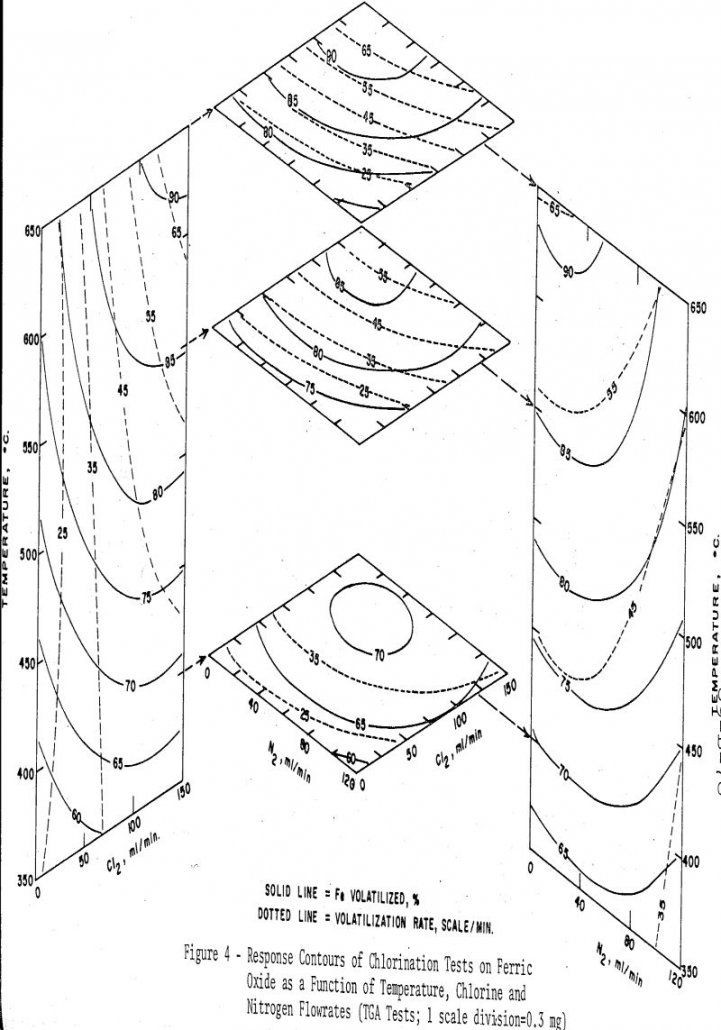

Manganiferous Iron Ore Chlorination

The chlorination behaviors of pure iron and manganese oxides were investigated by combining a thermogravimetric analysis (TGA) technique with batch-boat roasting followed by leaching. Ferrous and manganous oxides could be chlorinated readily, but, in the absence of a reductant, the higher oxides of both iron and manganese were difficult to chlorinate. Thermogravimetric analysis curves were […]

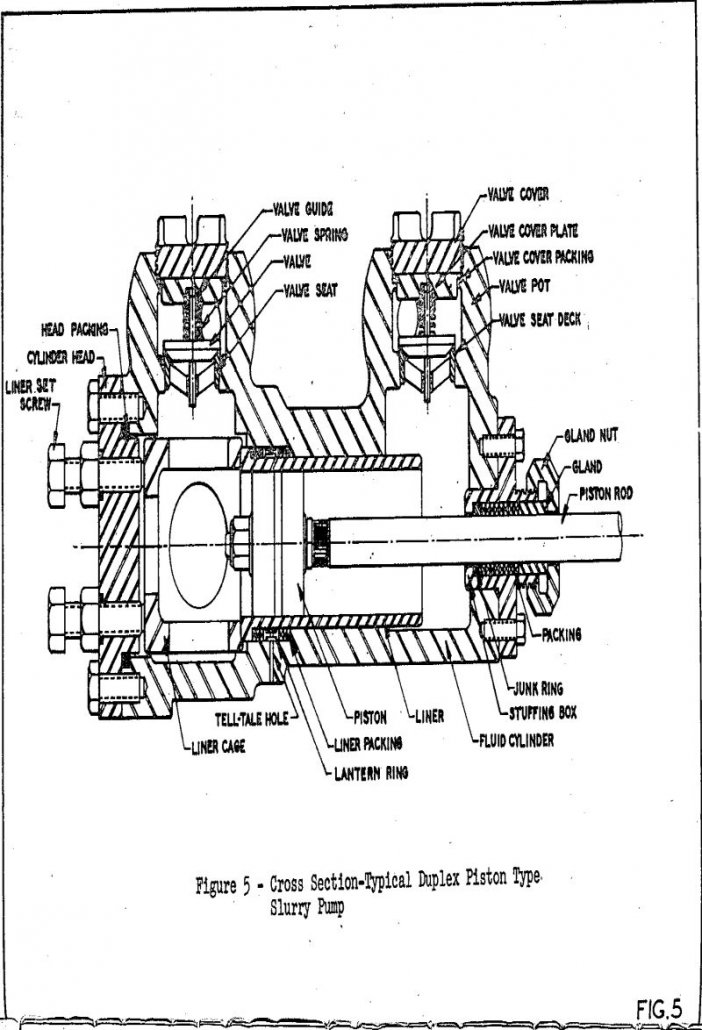

Slurry Pumps for the Long Pipelines

Since time immemorial, Mother Nature has been transporting slurries with both air and water serving as the carrier medium. Consider for example the formation of the continental shelves off our coast lines which are being formed by rivers emptying erroded land surface and depositing it into bays and gulfs. As the erosion processes take place, […]

Separation Efficiency

The technical excellence of separation achieved in a mineral concentration process, or any other process where two constituents of any kind are physically separated from each other, is expressed uniquely and quantitatively by the Separation Efficiency: Es = (R – Rg) where R is the percentage of the valuable constituent and Rg the percentage of […]

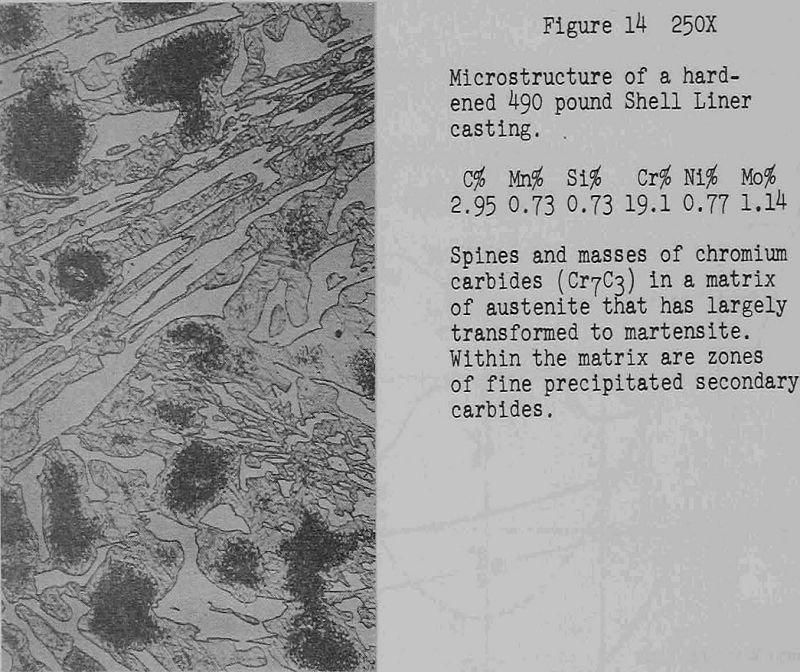

How to Select Grinding Mill Liner Alloys for Optimum Wear Resistance

The wear resistance of an alloy in heavy mill liner sections may be quite different from that of the same alloy in small balls and other light sections. This fact was established by means of a well standardized laboratory test that was validated for ball mill service. The salient properties of mill liner alloys, including […]

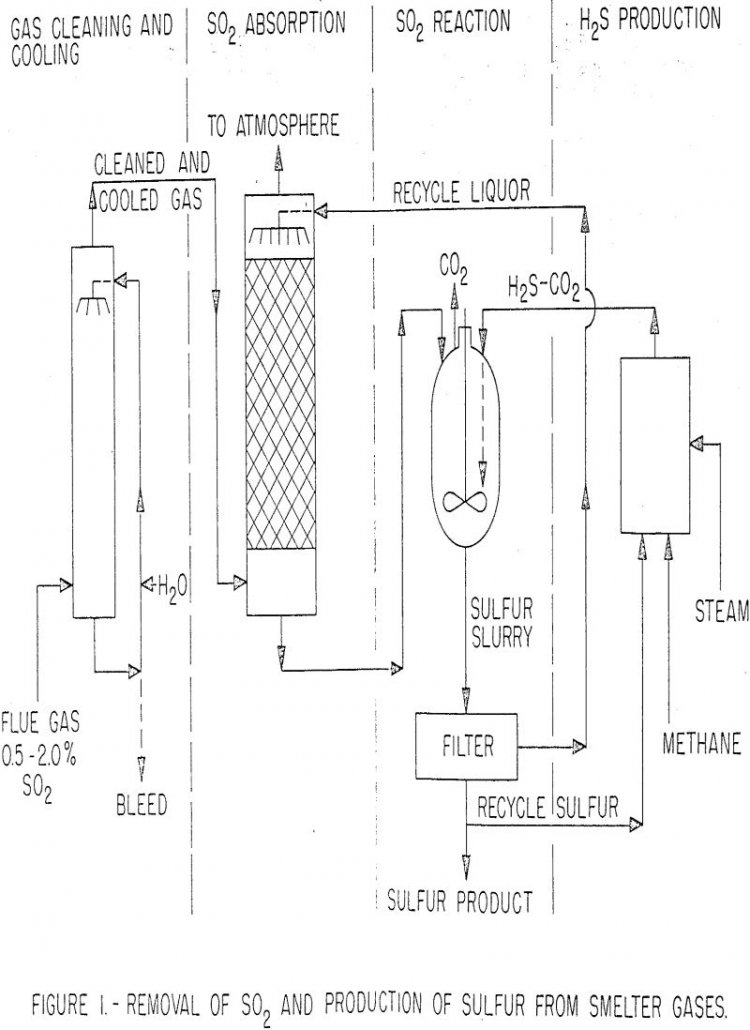

Removal of SO2 and Production of Sulfur from Smelter Gases

The economic removal of SO2 and production of elemental sulfur from stack gases discharged by base-metal smelters is a challenging-goal. Annually, in the United States, about 3.5 million tons of SO2 are discharged to the atmosphere by smelters. The SO2 concentration of the gases ranges from about 0.5 to more than 3 percent. As the […]

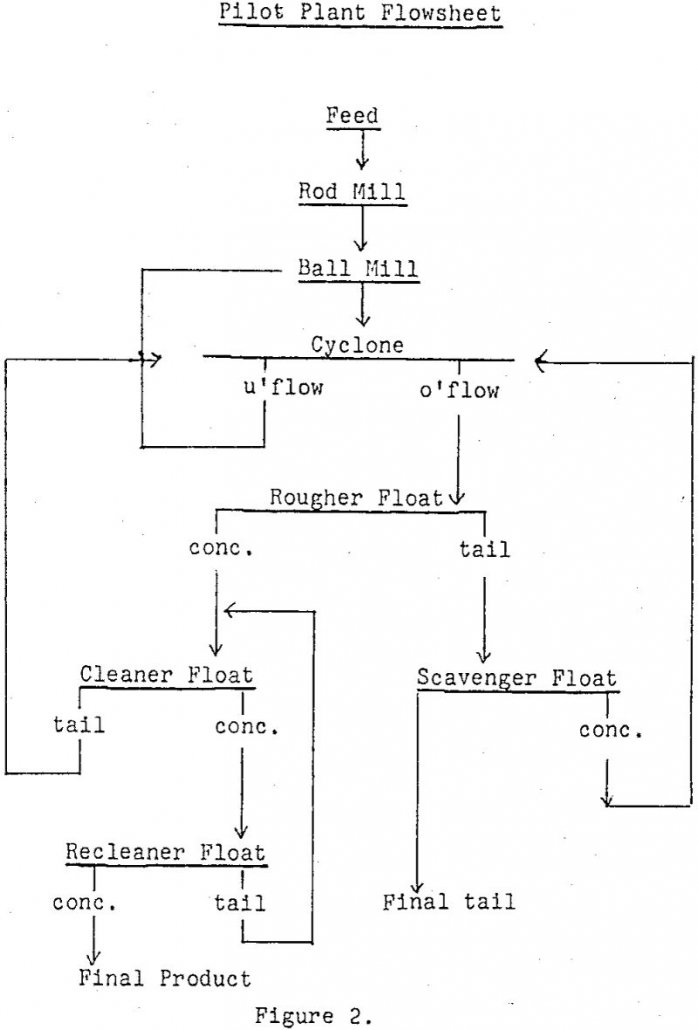

Recover Copper from Reverberatory Furnace Slag

Laboratory and pilot plant investigations have indicated that copper recoveries of 50% can be achieved with fine grinding and flotation of a copper reverberatory furnace slag. Microscopic and microprobe studies indicate that the recoverable copper is in the form of matte, chalcocite, and metallic copper; the percentage of copper in particles appearing to be copper-free was […]