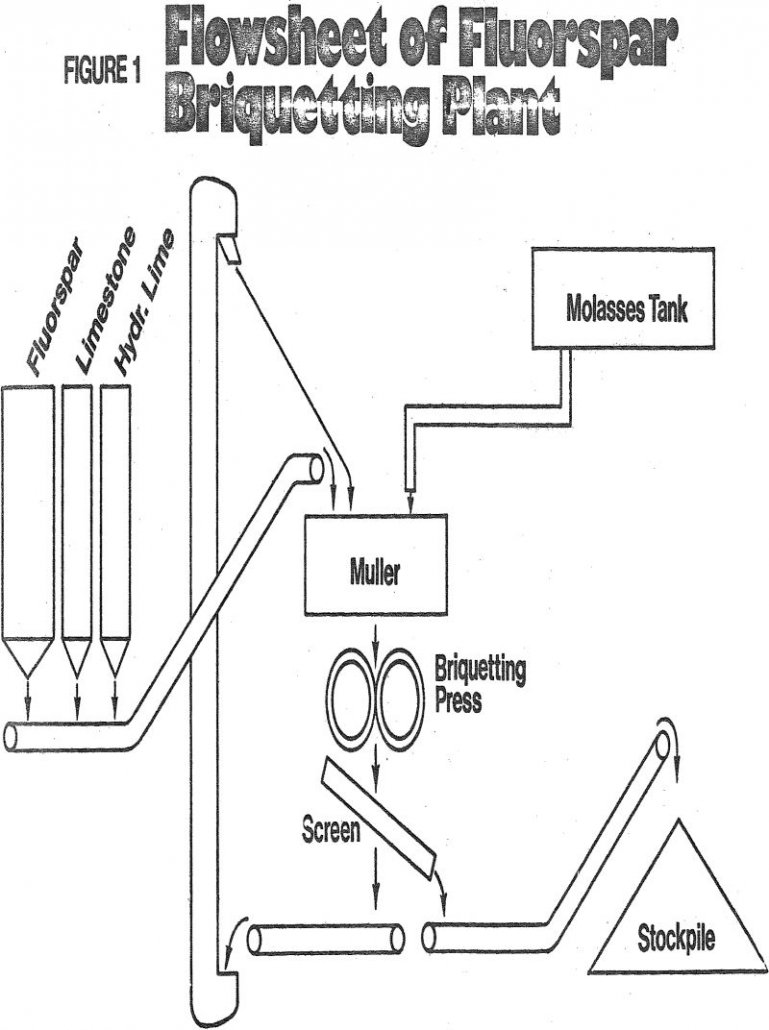

Metallurgical Grade Fluorspar Briquets – How Process

The Oglebay Norton Company has traditionally been a supplier of metallurgical grade fluorspar gravel to the American steel industry and, in the early sixties, fluorspar pellets were entered into the market. The gravel has been imported from Mexico, the pellets were produced by the Minerva Company in southern Illinois. Use of waterglass or tall oil […]

Predicting Particle Size Distributions in Open & Closed Circuit Mills

A size-continuous breakage kinetics model is postulated and supported with industrial grinding mill data. It is shown that the kinetics parameters include the effects of possible classification at the mill discharge. The estimated parameters were then used in the kinetics model to simulate the behavior of a grinding mill in open and closed circuit operation. […]

Potassium Salt Flotation from Salt Lake Evaporites

The U.S. Bureau of Mines and Great Salt Lake Minerals and Chemical Corp. developed a froth flotation process for concentrating potassium salts from Great Salt Lake solar evaporites containing about 5 percent K. The crude evaporites, which were predominately halite (NaCl) with smaller amounts of kainite (KCl·MgSO4·2·7H2O) and schoenite (K2SO4MgSO4·6H2O), were conditioned in a saturated […]

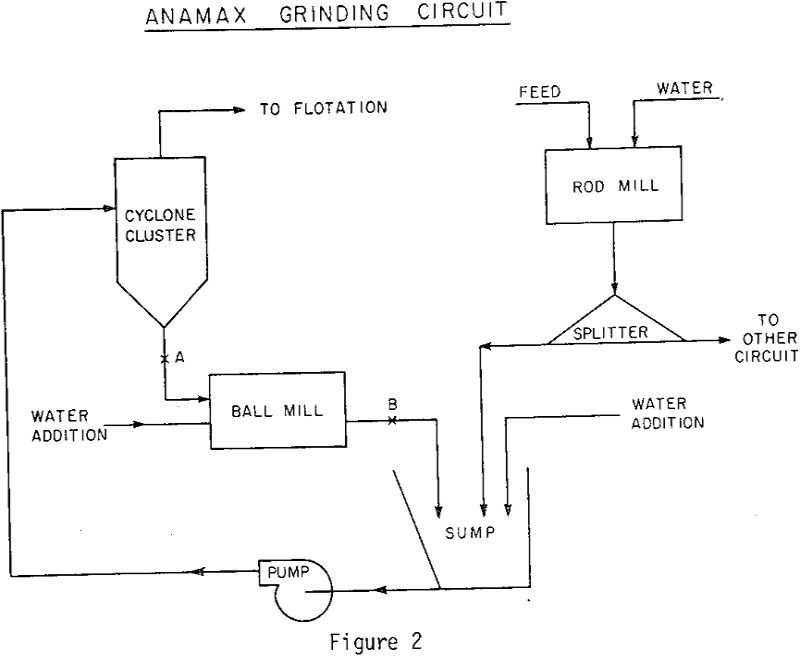

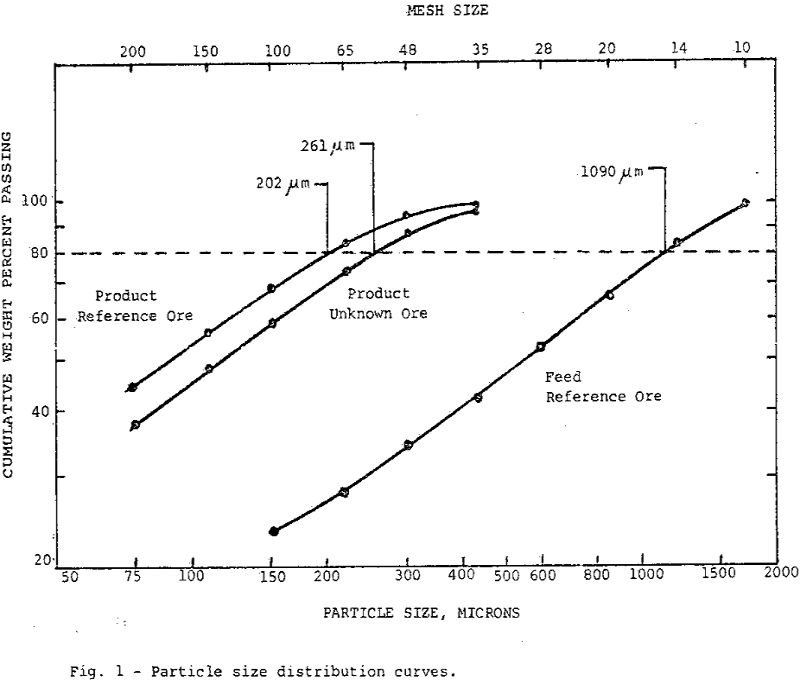

How to Use Ore Grindability to Evaluate Plant Performance

A number of methods to simulate the Bond work-index parameter are used and several of these methods have been reported in the literature. Smith and Lee used batch-type grindability tests to arrive at the work index. They made comparisons, at various grind sizes, with work index values using the standard Bond grindability tests. Another method […]

Analyse Mechanical Air Separator Selectivity Curves

Basically, a mechanical air separator is constructed with an inner shell and an outer shell. Material fed to a rotating plate is dispersed within the inner shell. Air, pulled in from the outer shell, passes upward through the descending curtain of dispersed feed, elutriating intermediate and fine material out of the feed. The elutriated particulates […]

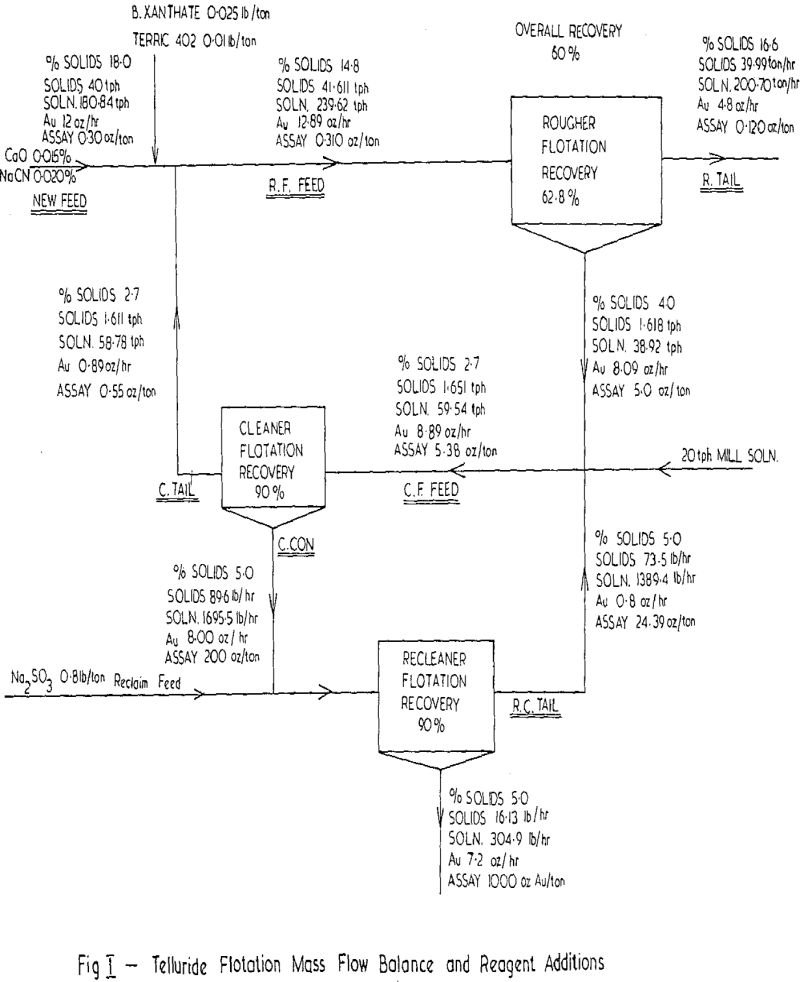

Leaching of Telluride

The plant has a capacity of 1200 tons (imperial) per day. The mode of the occurrence of the precious metals is complex, and the physical nature of the ore highly variable. The incidence of primary fines, at times up to 40%, is a major problem. Immediately after grinding in circuit (cyanide) solution, a telluride concentrate is […]

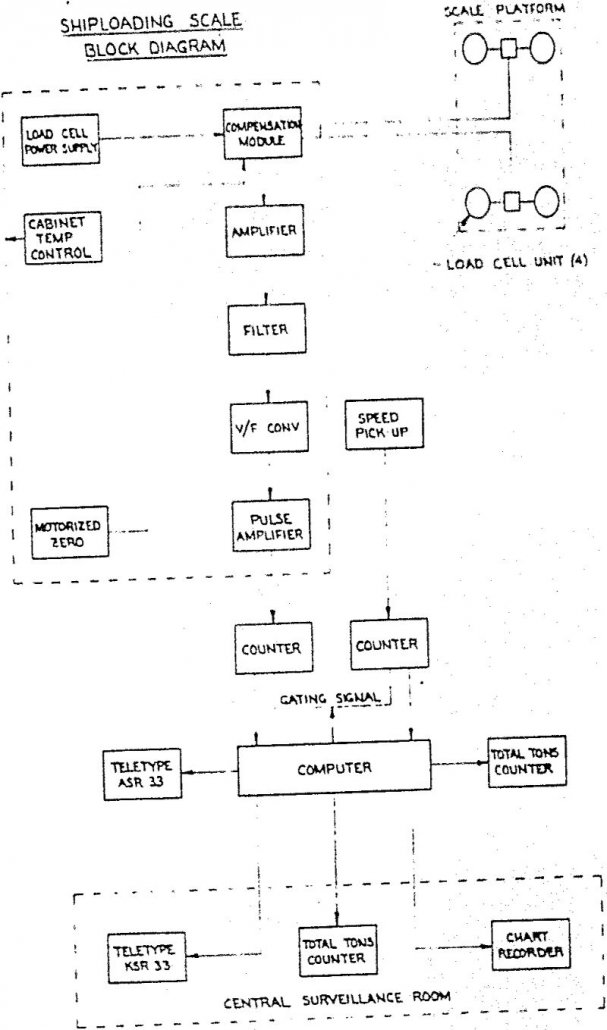

Design Criteria of a New High-Capacity Conveyor Scale

In 1971, during the planning and design stages of a $300 million expansion, the Iron Ore Company (I.O.C.) of Canada Ltd. through its Engineers, Canadian Bechtel Ltd., came out with a preliminary request for two 10,000 LTPH belt conveyor scale systems. These Systems were to provide weighing accuracies within ±.5% of the iron ore pellets […]

Heavy Metal Removal for Effluent Treatment

The mining and processing of basic metals relies on water as a medium for transport. Metallurgical ores are ground, concentrated, leached and refined in an aqueous medium. Water is used for temperature control during processing and in air pollution abatement during smelting. Treatment Technology The water and wastewater treatment technology required to meet treatment requirements […]

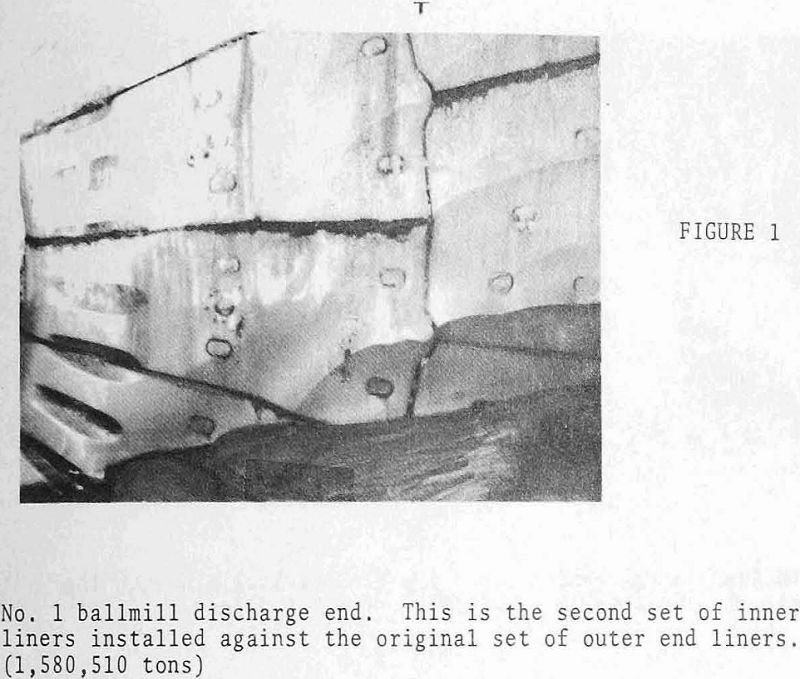

Pinto Valley Concentrator Grinding with Large Diameter Ball Mills

The Cities Service Company’s Pinto Valley mine and concentrator lie about 6 miles west of the town of Miami, Arizona at an elevation of approximately 4,000 feet above sea level. The concentrator started its first ball mill in July 74 and all six were available by November. Every effort was made to reduce capital costs, […]

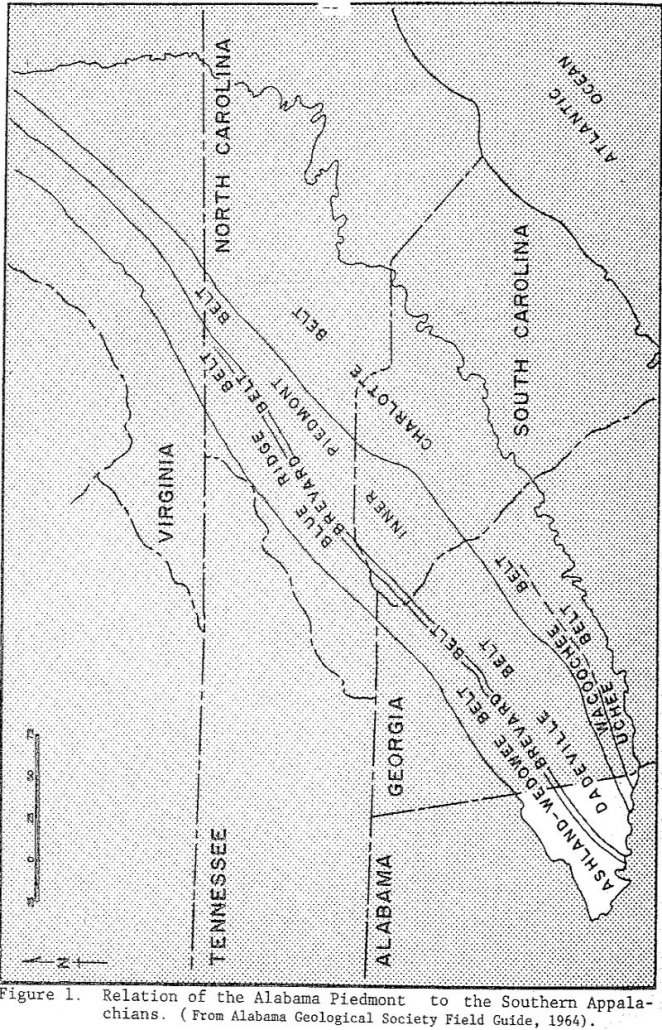

Geochemical Gold Prospecting

Gold was first discovered in Alabama in 1830. Before a decade had passed more than 20,000 people were employed in the various gold districts scattered across east-central Alabama. By 1849 most of the presently defined gold districts were known with such towns as Arbacoochee, Chulafinnee, Goldville, Pinetucky, and Idaho being the principal mining camps. The […]