How to Calculate an Open Pit Mine Capacity

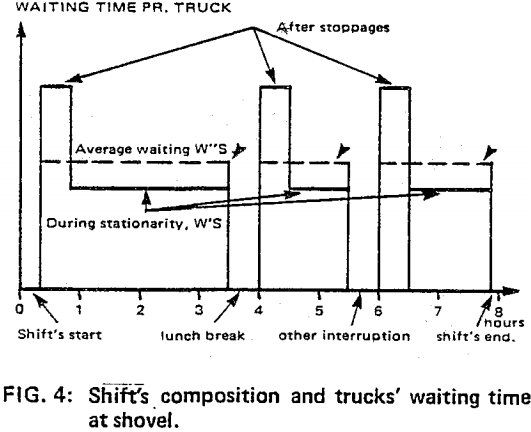

The calculation of open pit operations’ capacities has been the subject of many studies using computer simulations. The common problems of simulation are that if one desires a realistic picture of an operation the programming work becomes long and expensive and that the program requires a large computer and long time to run. The method […]

Calculating Mass Flow Balances

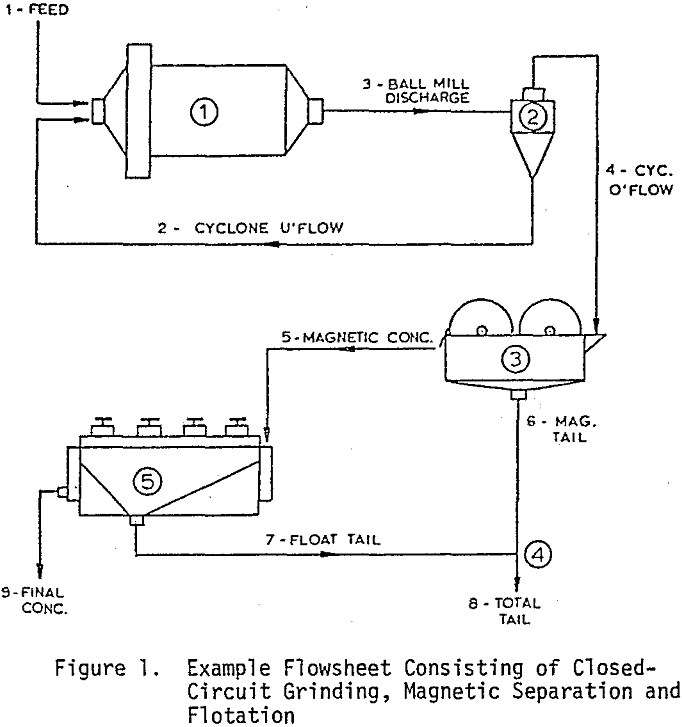

Calculating material flows from analytical data by means of the standard two-product formulas grew increasingly difficult and time-consuming as the complexity of the flowsheets increased and as choices between conflicting analytical values had to be made. Mathematical Formulation of the Problem Any metallurgical flowsheet can be represented by a set of directed lines called branches. […]

Belt Conveyors of Large Carrying Capacity Resistance to Motion

The frictional resistance to motion of a belt conveyor has always been a subject of intensive studies and research by engineers throughout the years. Numerous informations have been developed by analysing series of field tests on belt conveyors of different characteristics and carrying different materials at various capacities. Within certain limits of weight per unit length […]

Belt Conveyor Drives Factors & Selection

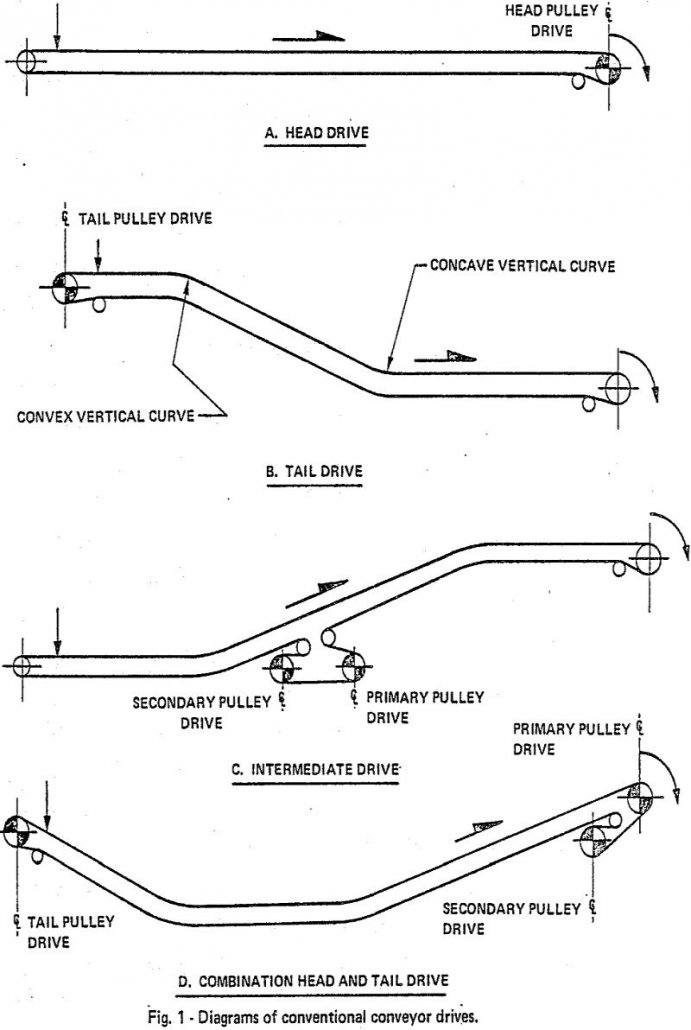

Conventional belt conveyors are powered by electric or electro-mechanical drives mounted at the conveyor’s head, tail, intermediate return span, or a combination of these. The following are main elements influencing the selection of the drive system: 1) dynamic characteristics, 2) economic factors such as capital cost, plant spares compatibility, reliability, availability, maintainability, and 3) environmental constraints. […]

Ball Mill Charging System

Mill ball charging systems have undergone little change during the past two decades. Most operations utilize a locomotive/ball car combination to load and haul charges from the ball storage bin to the mill charging boxes or, alternatively, transport charges to the charging boxes by means of a ball bucket handled by bridge crane. The grinding […]

Automatic Grinding Mill Control

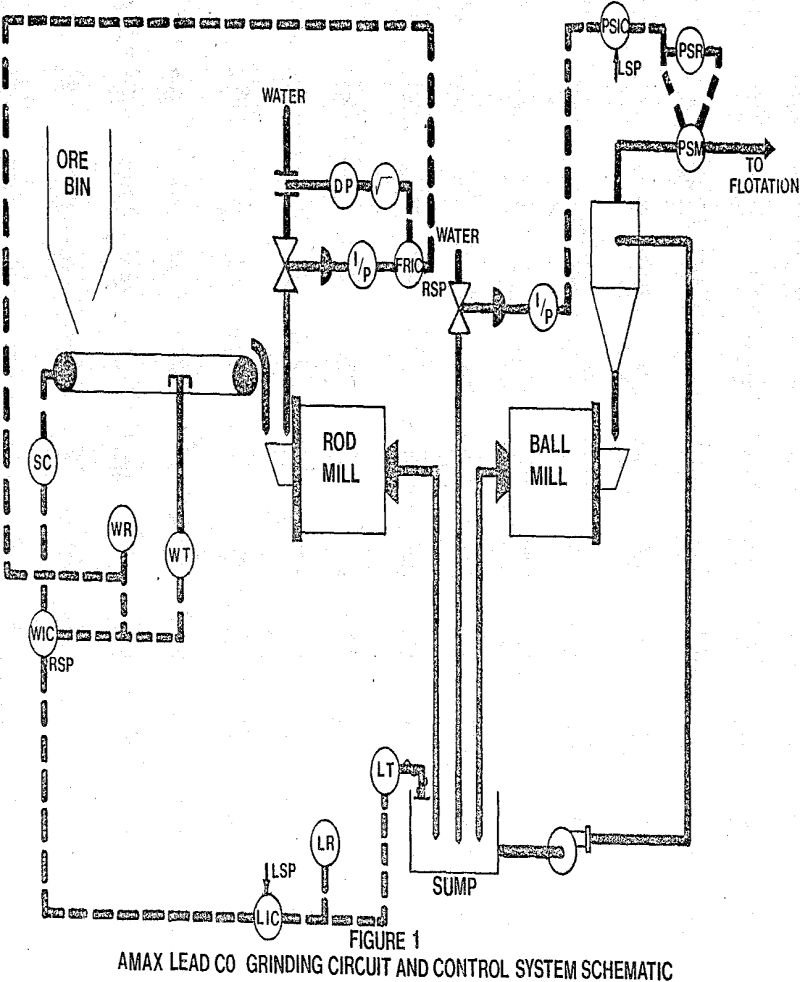

There are presently in use many grinding mill control schemes and concepts. In this case, one operating method of controlling the particle size of the cyclone overflows for proper metallurgical results and controlling the level of the cyclone feed sump and new feed rate to obtain lowest unit cost of finished (ground) material which is […]

Gangue Assay

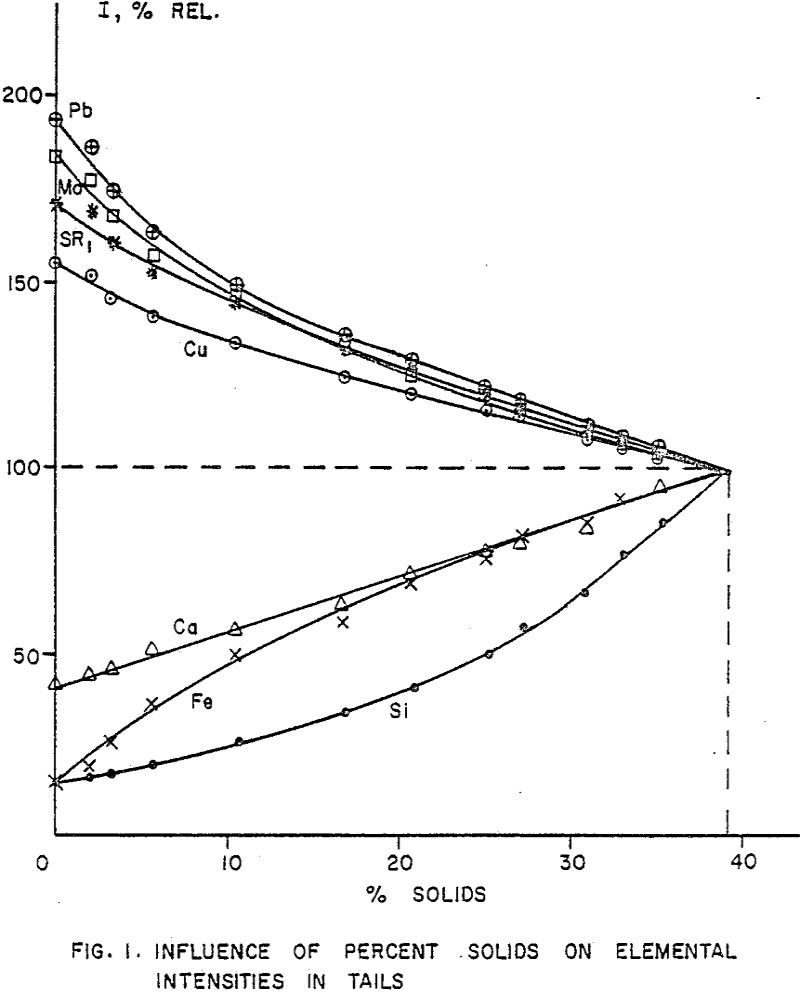

On-stream analysis is a much more rapid means of obtaining true assays of a flowing product when compared to wet chemistry or “grab” samples dried, briquetted and assayed by x-ray. In contrast, on-stream analysis uses real time samples assayed every 30 seconds while each stream is assayed every 5 to 15 minutes. The main physical […]

Copper Sulfide Leaching by Ammoniac to recover Sulfur

Results of a preliminary study of the ammoniacal leaching of covellite (CuS) in an aqueous oxidizing system in the presence of a non-miscible organic sulfur solvent are described. Up to 60% of the sulfur can be recovered from the solvent as elemental sulfur while achieving high degrees of solubilization of the mineral. Experimental Leaching tests, […]

Hydrometallurgical Copper Extraction Process

The successful development of the Cyprus Copper Process has been an evolutionary series of events covering a time span of some seven years. What does the Cyprus Copper Process do? Very simply, it converts copper concentrates of varying composition into copper metal which has been proven to be equivalent in every way to electrolytic tough pitch […]

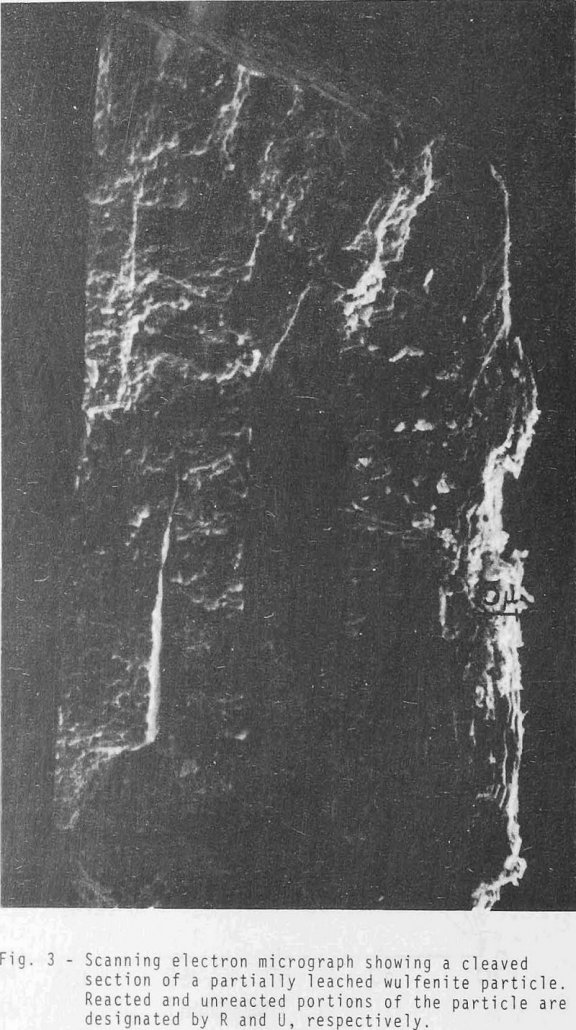

Sulfide Ion Leaching Kinetic of Wulfenite

The principle oxide minerals of molybdenum are wulfenite (PbMoO4), ferrimolybdite (Fe2(MoO4)3·nH2O), powellite (CaMoO4), and ilsemannite (Mo3O4). Wulfenite is found in Arizona, New Mexico, Nevada, Utah, California, and Montana. It is also found in the states of Sonora and Chihuahua, Mexico. Prior to 1915 wulfenite ores were the primary source of molybdenum. All leaching experiments were […]