Effect Grinding Media on Selective Flotation of Copper Lead Zinc

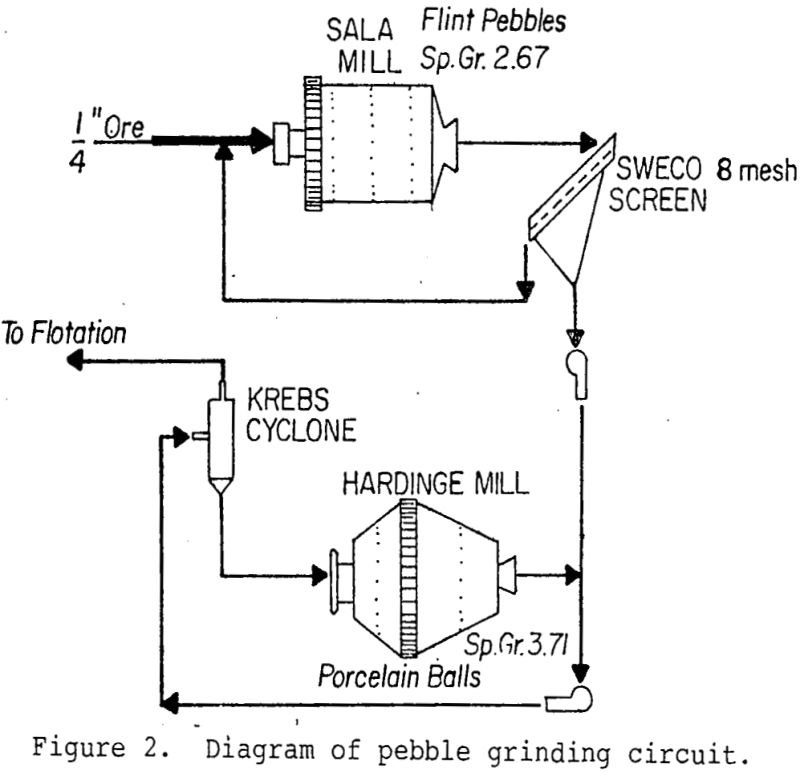

The normal practice for processing complex sulphide ore has been to grind with steel balls and/or rods in steel mills before flotation. Little thought had been given to the effect of grinding media on flotation selectivity of copper – lead zinc ore. Ore Sample The mill feed for the pilot-plant investigation was from a copper-zinc […]

How Rotary & Spray Drying of Copper Concentrate Compares

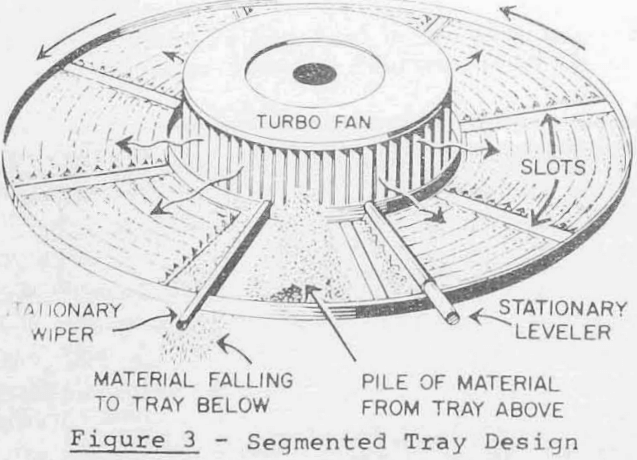

The rotary drying system consists of a final concentrate thickener to dewater the slurry to about 60%-70% solids; a vacuum filter (disc or drum) with the necessary vacuum pumps to dewater the thickened material further to about 14%-20% moisture on a dry basis; a collecting belt underneath the filter to receive the filter cake; a […]

Drying & Calcining Ammonium Diuranate

‘Yellow cake’, so named because of its inherently bright yellow color, is a finely divided precipitate that can be formed after the leaching step when refining uranium ores. Feed solids enhancement then occurs to at least 50% by weight using filters or centrifuges. This is followed normally by drying and then calcining with the conversion […]

Waagner-Biro ASL Liner System

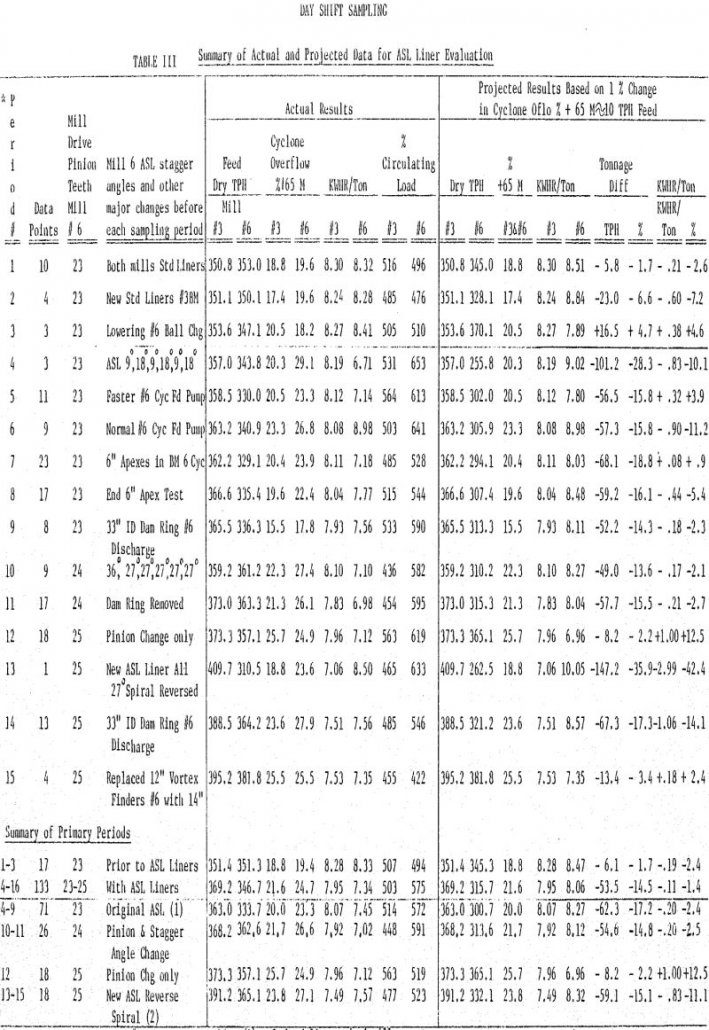

A unique type of grinding mill liner has been developed by Waagner-Biro A.G. of Austria. This liner system, termed an angular spiral lining (ASL), was successfully tested by Magma Copper Company’s San Manuel concentrator in both their 10 Ft x 10 Ft (3.05m x 3.05m) and 12 Ft, 6 In x 14 Ft (3.31m x […]

How to Treat Water Containing Cyanide

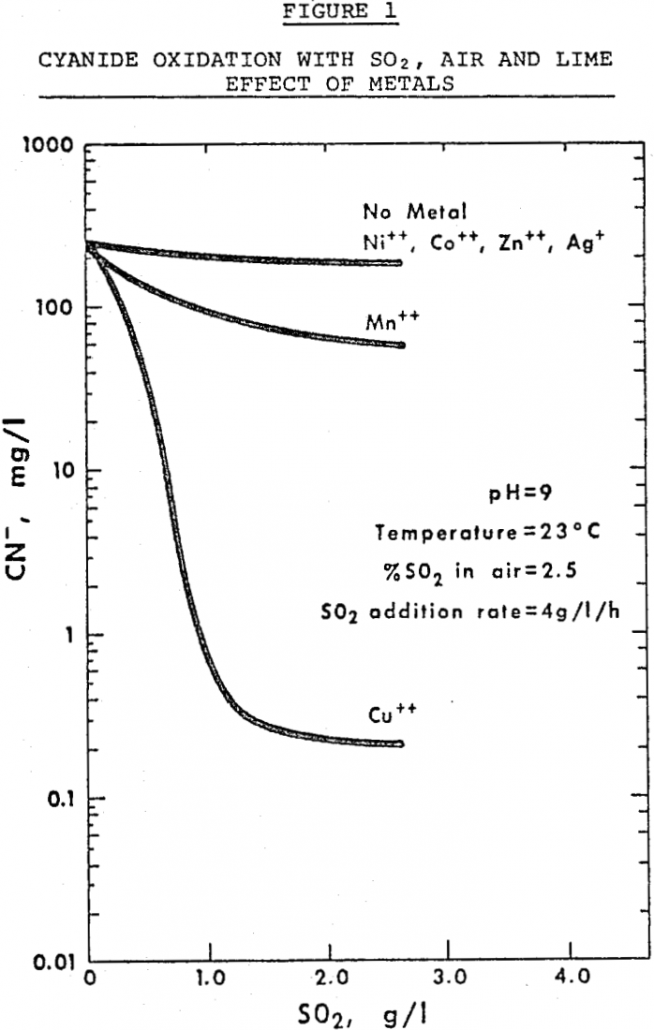

Metallurgical processes involving the use of cyanide such as gold cyanidation, metal plating and flotation, generate effluents containing cyanide and cyanide in complex combinations with heavy metals in quantities exceeding those regarded as being safe for discharge into streams. A new, inexpensive method for removal of cyanide, combined cyanide and related species from wastewaters has […]

Carbon-In-Pulp Process Examples

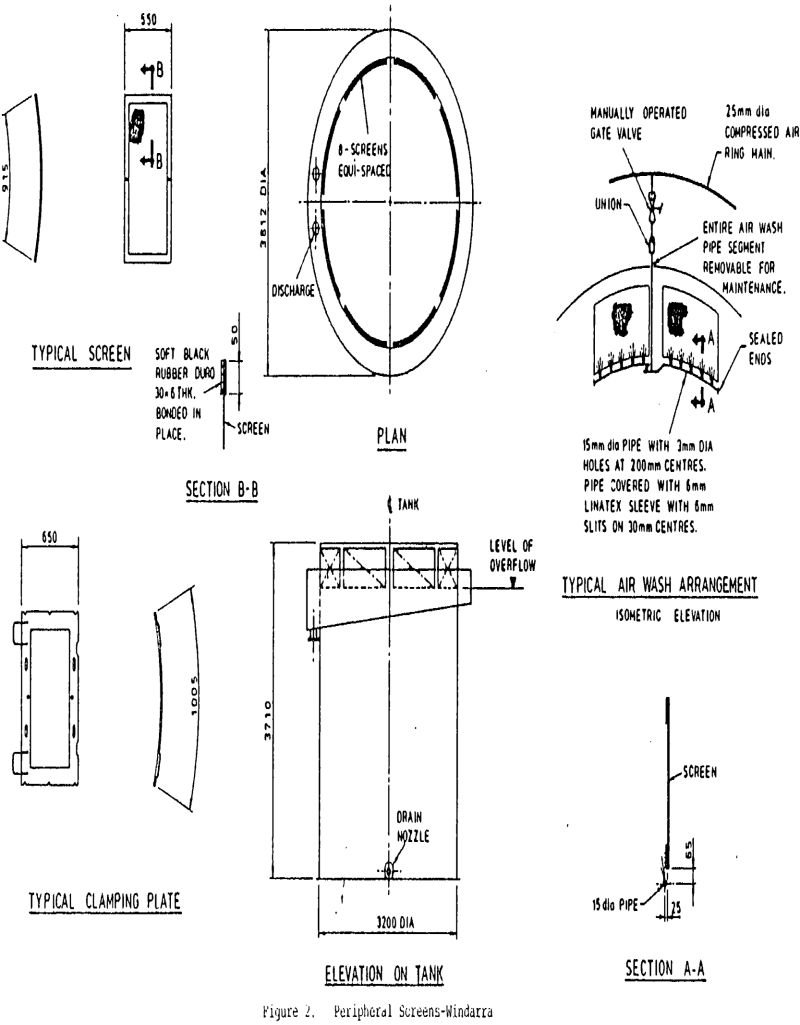

There are no major innovations in any of these plants. In fact, Australia is really only beginning to get started in CIP research and in process and design development. The plants described here have borrowed from technology, primarily in the United States and South Africa, and although the plants were carefully designed and based on […]

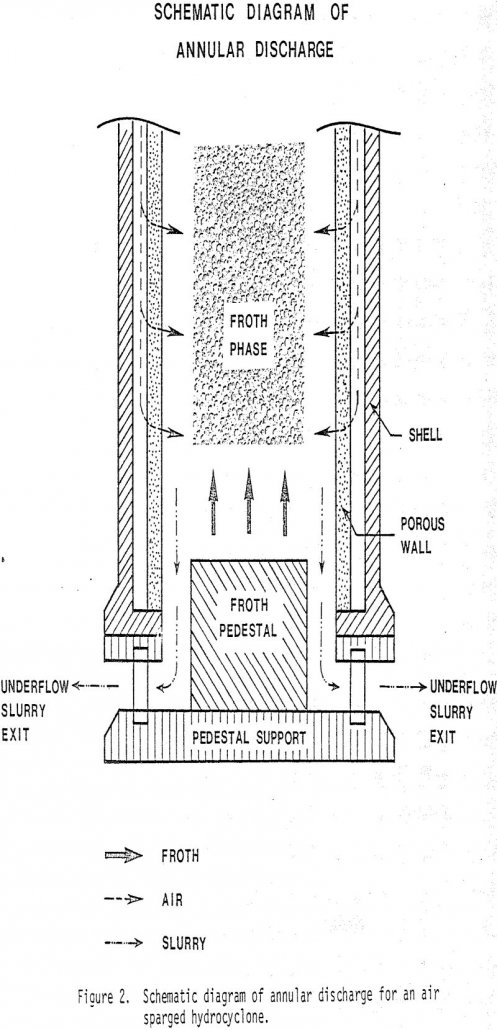

Swirl Flotation in Centrifugal Field by Air Sparged Hydrocyclone

The effects of operating variables on water transport to the overflow, classification of hydrophilic particles and the recovery of copper and molybdenum from a low-grade porphyry ore are presented. Recoveries of copper and molybdenum exceeding 90 percent at a grade of 8 percent Cu and 0.2 percent Mo were realized for minus 100 mesh (149 […]

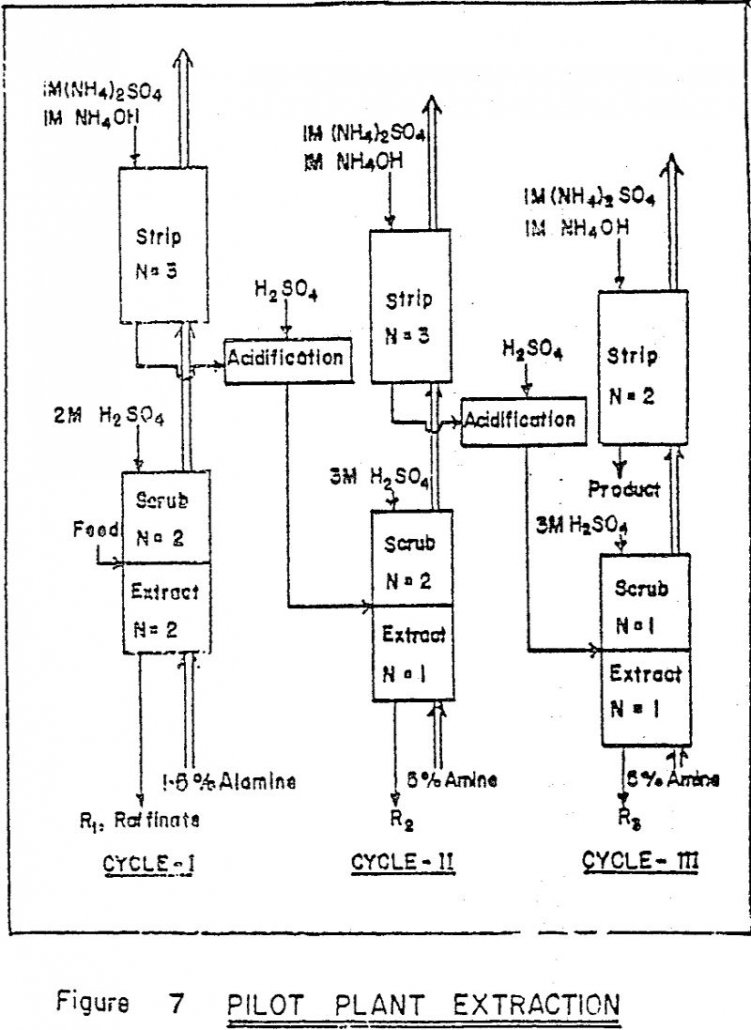

Recover Rhenium by Solvent Extraction

Rhenium is industrially recovered all over the world as a by-product of molybdenite processing. There are no separate deposits of rhenium minerals. Molybdenite concentrates, produced as co-products of porphyry copper deposits, contain 0.01 to 0.2% rhenium occuring as a substitutional impurity in the molybdenite lattice. Process Synthesis The solvent extraction process is integrated with other […]

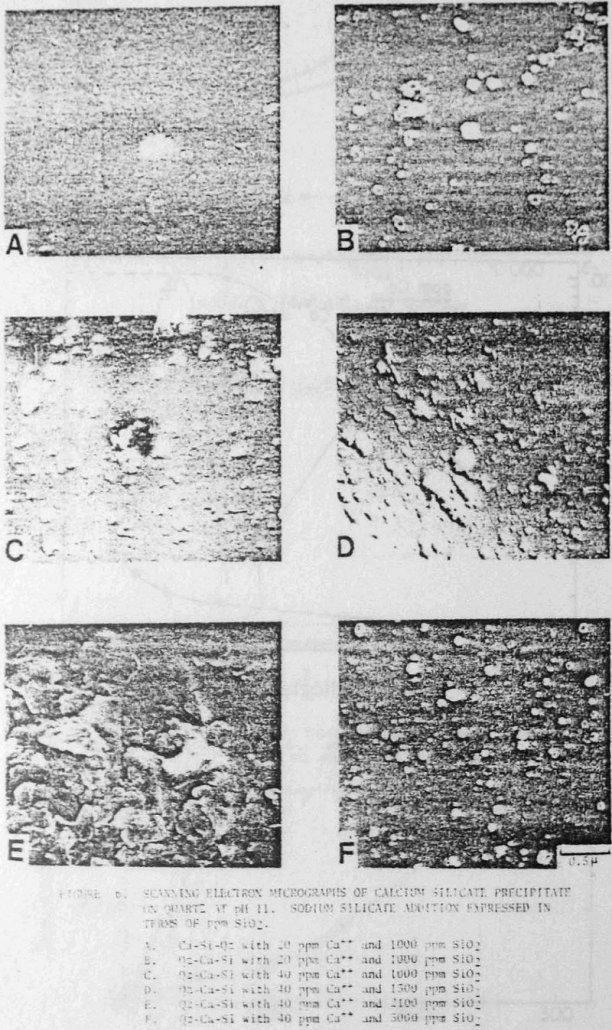

Use Sodium Silicate as Dispersant in Selective Flocculation

In the upgrading of finely-disseminated iron ores, selective desliming is the critical step which must be controlled in order to achieve efficient flotation. A prerequisite for selective desliming is a properly-dispersed pulp; sodium silicate is commonly used as a dispersant. The mechanism by which sodium silicate acts as a dispersant in the presence of calcium […]

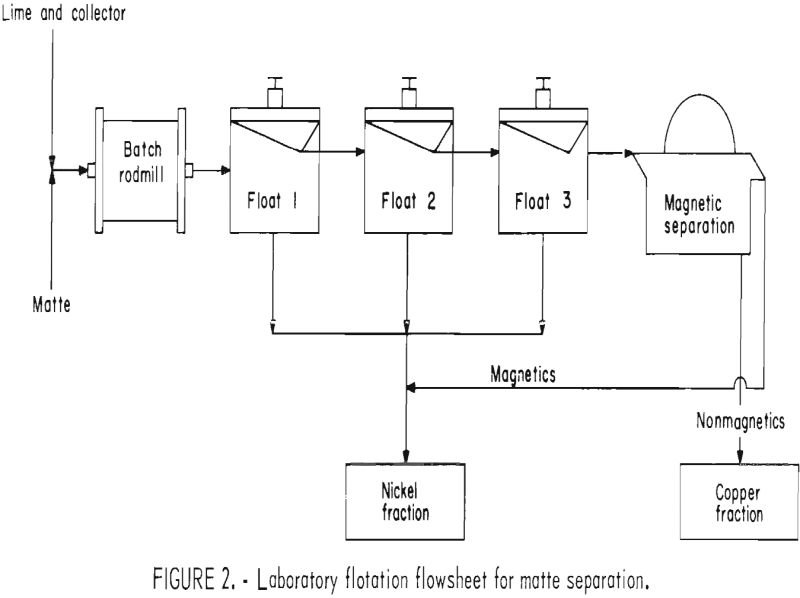

Separation of Copper-Nickel by Flotation and Magnetic Methods

As part of our mission to investigate technology options for the development of domestic mineral resources, conducted tests aimed at separating the copper-nickel values in bulk sulfide mattes into copper-rich and nickel-rich fractions. Resources in the Duluth Gabbro Complex are estimated to be 4.4 billion short tons of mineralized rock grading more than 0.50 pct […]