Mining Methods

The mines and mining methods of the now defunct Arizona Mining Copper Co. are situated in the Morenci-Metcalf copper district in southeastern Arizona. This copper-bearing district covers a triangular mountainous area of about 3 square miles, rising abruptly from the gravel plateau of the surrounding country. In this area, an immense intrusion of porphyry has […]

Merrill Crowe Process & Equipment

Here is described the essential features of the Merrill Crowe Process and its equipment/apparatus used for the Simultaneous Clarification, De-aeration and Precipitation of cyanide solutions. Limited space has prevented a full description of all of the details involved but we have pointed out the application of the various types of equipment and the advantages to be […]

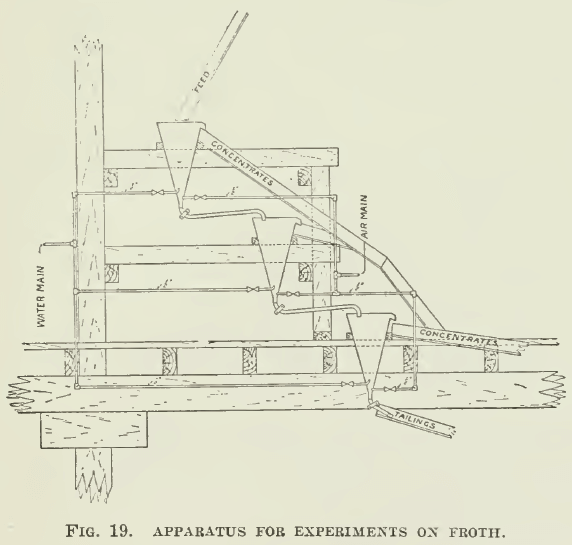

How Froth Flotation was Discovered and Developed

While concentrating the galena in the lead ore produced from the Central mine, a valuable by-product was obtained in the form of slime assaying 18% lead, 20% zinc, and 16 oz. silver per ton. This came from an ore in which quartz and rhodonite were the chief gangue-minerals. In the course of ordinary operations, it […]

Flotation Principles

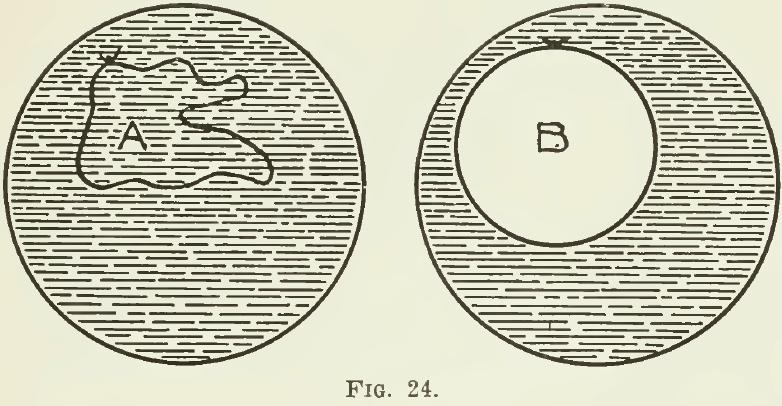

Flotation, in its latest phase, is a process of concentrating ores by frothing. When crushed ore, previously mixed with water and a relatively minute addition of oil, is agitated violently in the presence of air, a froth is formed. This froth, rising to the surface of the liquid mixture, is laden with sulphides or other […]

Flotation using Acid

The mineral that is two millimetres and under in size is sent to the Hardinge mills for re-grinding. These mills are 10 ft. diam. by 4 ft. long, and are in closed circuit with simplex Dorr classifiers, one classifier to each mill, 6 mills to the section, and 8 sections in the establishment. The overflow […]

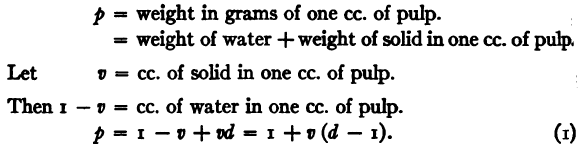

Pulp Formulas & Metallurgical Formulas

Definitions. “Pulp,” in flotation terminology, is a freely-flowing mixture of powdered ore and water. “Pulp density,” when the phrase is applied properly, indicates the specific gravity of the pulp. “Percentage of solids” means the ratio, expressed as a percentage, of the weight of the solids in a pulp to the total weight of pulp. “Pulp consistency” is the ratio, […]

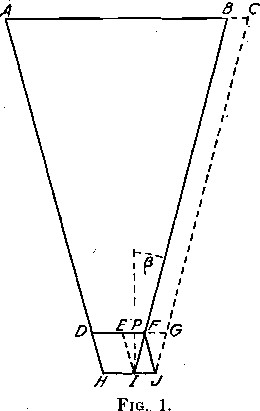

Factors Controlling the Capacity of Rock Crushers

When estimating the capacity of crushers under given conditions, it is necessary to employ an empirical factor which has here been designated by the letter k, representing the percentage ratio between actual crushing rate, and a theoretical capacity based on the dimensions and other data correlated in equation (12). The accuracy of this factor limits […]

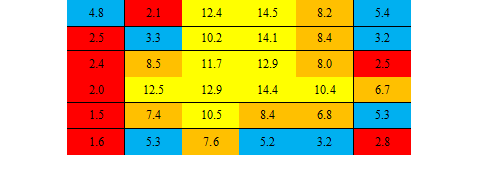

Geometallurgy: Integrating Geology and Metallurgy

The variability in gold recovery (geometallurgy) is a very important problem to study during the first steps of the project and even during the operation. Probably, the explanation of that problem for some plants is not well known and the problem has to be solved with valid criterion that were not considered during the design […]

List Gold Metallurgical Tests

In order to have a preliminary idea about the metallurgical performance of the samples, some scoping tests have to be performed. They can be carried out in the prospective mine site and/or special metallurgical laboratory. The final election is based on the equipment availability and gold mineralization. Test to be done include; concentration by gravity, […]

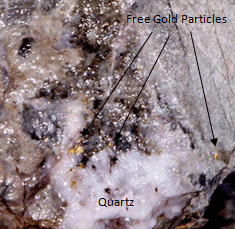

Process Mineralogy

The treatment of auriferous ores presents several challenges to the metallurgists and plant operators due to there are some factors that have an important impact on the process. Without any doubt the mineralogy is the key aspect of the process performance. Basically, there are several options to be considered at the moment of evaluate the […]