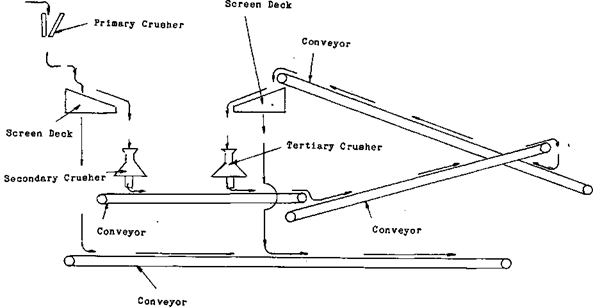

Balancing a Crusher & Vibrating Screen Circuit

To understand the effects the plant has on itself during its actual operation is very important. There are three variables that the plant on a whole is affected by: VOLUME (or tonnage) SIZE OF FEED CIRCULATING GARBAGE (wood, plastic, rubber, etc.) The first two the volume and the size of the feed effect one another, […]

Polyurethane Screen Panels

These Polyurethane Screen Panels are often installed on SAG discharge trommel screens or AG vibrating screens and even crusher circuits. Polyurethane Screen Panels are best when made of low “durometer” Polyurethane to allow a “bouncing” effect for the rocks and reduces wear.

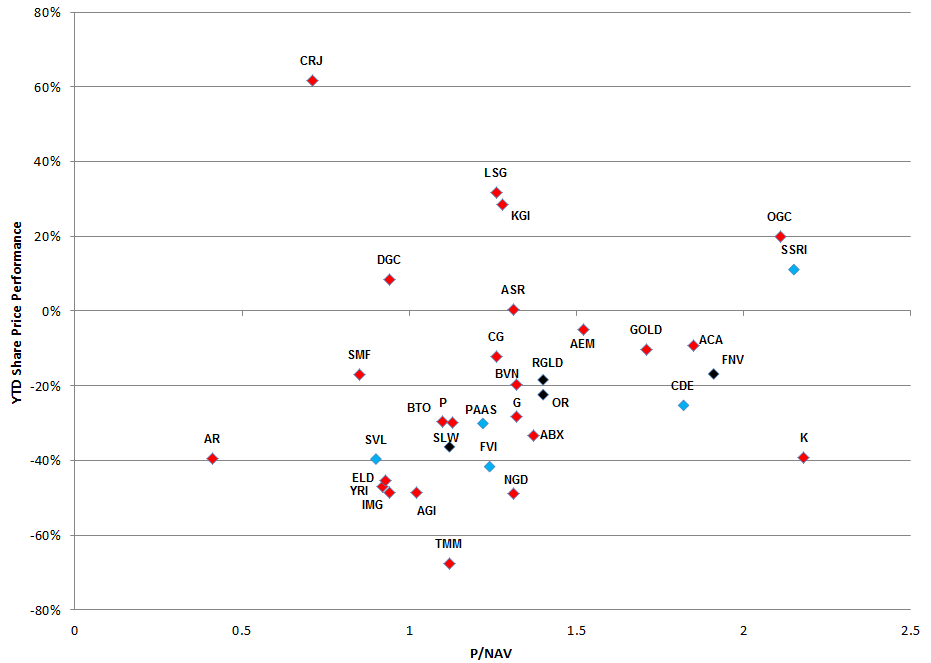

Five Gold Stocks to Buy Now

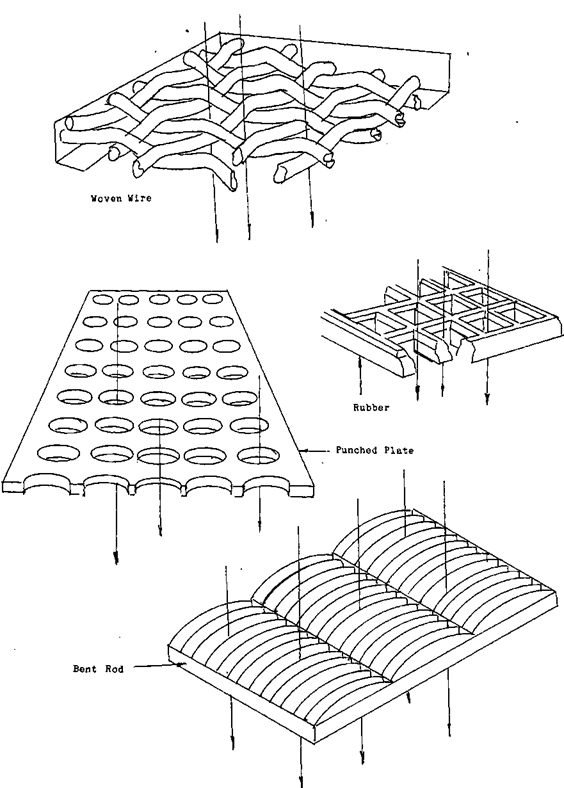

Various Types of Screen Decking

In some designs it is very easy to replace portions of the deck in just a few minutes. In the bigger screens to replace just a portion takes time, with these decks a screen will be temporarily patched. Just putting a patch on does two things, first allows the repair to be done when it […]

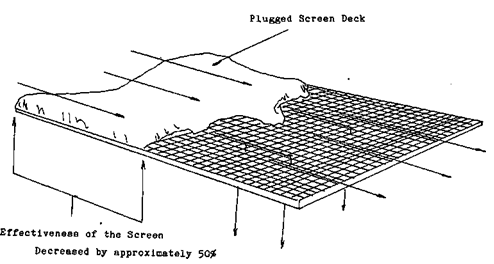

Effect of Moisture on Screen Efficiency

When you are supervising a set of screens these are the variables that you have to watch for: SPEED OF VIBRATION: DEGREE OP SLOPE: TONNAGE: WETNESS or Moisture OF THE ORE: MECHANICAL CONDITION: The operator will have two or three indications that As an operator you have control over two of these variables, mechanical […]

Crusher Operating Variables

Now is the time we start-talking of operating variables of crushers. I will talk about the crushers first, then the screens, and finally both together as a circuit. The variables for the crushers are: SIZE OF THE FEED, SPEED OF CRUSHING, THE HARDNESS OF THE ORE, MECHANICAL CONDITION, SIZE OF THE FINISHED PRODUCT, All of […]

Checking Crusher Gap -Measuring Crusher Chamber Spacing

To check the gap on a crusher a procedure called LEADING is done. A lump of lead, whose dimensions are greater than the gap of the crusher, is lowered through the crusher while the crusher is running. The lead is pulled back through the crusher very slowly to be sure that it is flattened as […]

Vibrating Screen Working Principle

When the smaller rock has to be classified a vibrating screen will be used. The simplest Vibrating Screen Working Principle can be explained using the single deck screen and put it onto an inclined frame. The frame is mounted on springs. The vibration is generated from an unbalanced flywheel. A very erratic motion is developed when […]

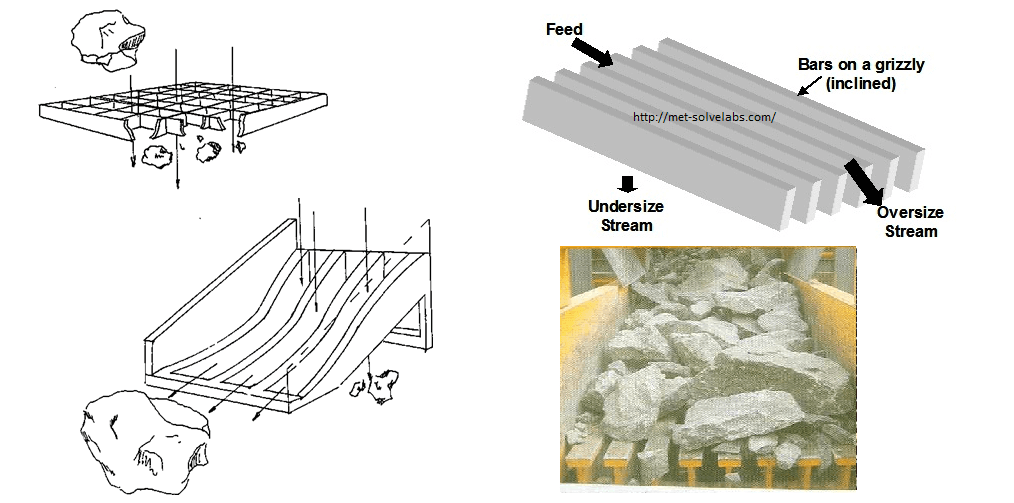

Static Grizzly Screen as a Rock Separator

The screening a Static Grizzly separator does is sort and classify the rock according to size. The first stage is SCALPING. This is the practice of removing any material that may slow production. It may be rock that is too big for the equipment to effectively handle, or fine material that is taking up valuable […]

Gyratory Crusher & Cone Crusher Mantle Differences

Any of you that are at all familiar with the Gyratory crushers and Cone Crushers that the former are used as Primary crushers will probably note many similarities between the types. Each use a cone shaped crushing surface, and the same principal in the eccentric is employed to develop the crushing action required. The difference between […]