Laboratory Flotation Testing

Batch Laboratory Flotation Testing starts from the 3 fundamental types of flotation processes or methods which can be classed as either: Bulk flotation Differential flotation Sequential flotation While all flotation processes are selective or differential in that one mineral or group of minerals is floated away from accompanying gangue, bulk flotation generally refers to separation […]

Causes of Dam Failure -Video

This shows an good video example of the cause of tailings dam failures.

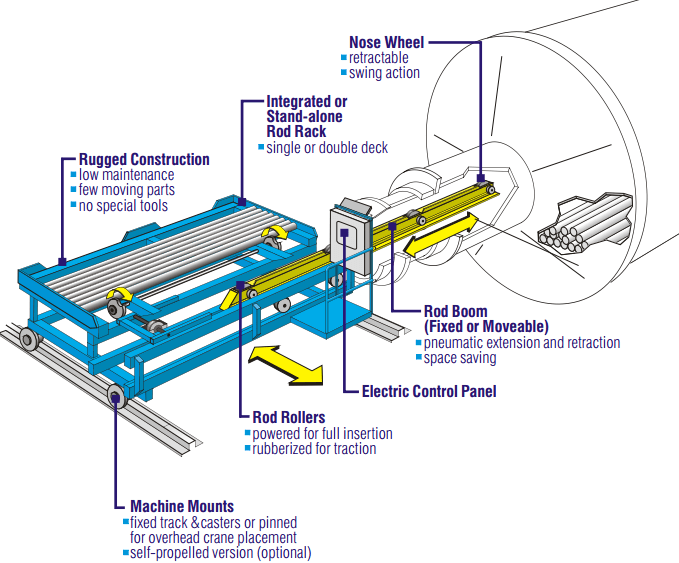

How to Charge Rods into a Rod Mill

Rods are loaded or charged into a Rod Mill using a mechanised charger. The rod charger with extendable boom moves rods safely inside the trommel/trunnion before charging with a typical 30 seconds or less cycle time per rod. How you charging a rod mill is best explained by the video below. https://heathandsherwood64.com/products/mpe/grinding and https://www.mclellanindustries.com/rodcharger.html sells them.

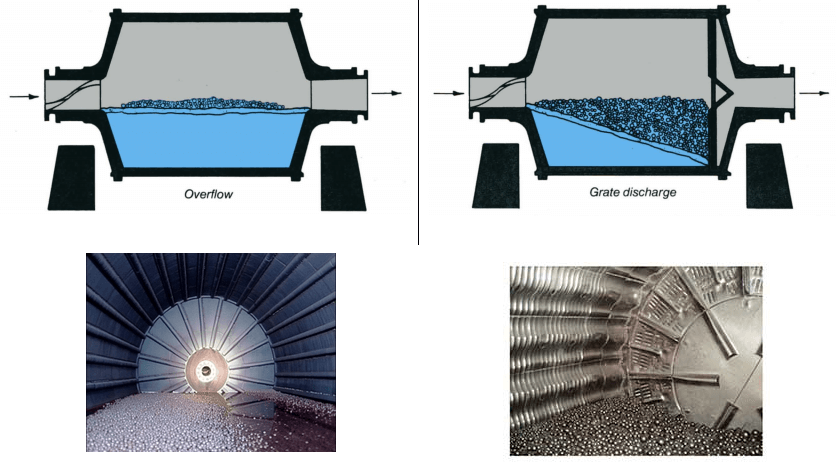

Overflow VS Grate Discharge Ball or Mill – Why Retrofit

Allow me to compare: Ball mills can be of the overflow or of the grate discharge type. Overflow discharge mills are used when a product with high specific surface is wanted, without any respect to the particle size distribution curve. Overflow discharge mills give a final product in an open circuit. Grate discharge mills are used when the […]

Column Leaching Procedure

1) For better Column Leaching, Agglomerate ore if required. The procedure is to cure for recommended time period. During this time the ore should be kept damp via a wet cloth spread over it. 2) Load ore into the column. This should be done with the column on an angle, and the ore poured gently in to […]

Cyanide Gold Extraction Process

Here is a method on how to conduct a cyanidation bottle roll test AKA Cyanide Gold Extraction Process: Riffle out 400 grams of the ore. Grind to pass 200 microns (“13-15 minutes for hard rock ores;” 10 minutes for oxidized ore) grind at 35% solids. Wet screen. Retain and dry fractions. Settling overnight of – 45um […]

Cyanide Bottle Roll Leach Test – Leaching Procedures

List Equipment Required to Perform of a Standard Bottle Leach Test Winchester bottles, with tops Plastic tape to seal tops of bottles Flexible air lines for possible aeration requirements Magnetic or mechanical stirrer for agitation Timer, pH meter, thermometer and weighing device Leachants, i.e. acid, alkaline or neutral solutions, or specific solutions Filter: vacuum or […]

Sulphide Leaching

Methods of leaching sulphide ores can be: in absence of oxidizing agents in presence of oxidizing agents Bacterial leaching Absence of oxidizing agents Acid leaching: Dilute acids dissolve some metal sulphides with liberation of H2S, e.g. ZnS + 2H+ ^ Zn2+ + H2S Three types of sulphides can be encountered. Completely soluble sulphides: Zns, CoS, […]

Cassiterite & Wolfram and Scheelite Leaching – Oxide

Natural cassiterite on account of its crystalline nature is extremely difficult to dissolve in acids or alkalies. Artificial cassiterite on the other hand is amorphous and soluble in acids. Cassiterite can easily be reduced however to Sn, which soluble in acids or alkalies. Pressure leaching has been applied to cassiterite concentrates using Na2S and NaOH […]

Gold Metallurgy and Leaching Process

Leaching, often gold, is the process of extracting a soluble constituent from a solid by means of a solvent. In extractive metallurgy, of gold, it is the process of dissolving a certain mineral (or minerals) from an ore or a concentrate, or dissolving certain constituents from materials such as a calcines, mattes, scrap alloys, anodic slimes, […]