Table of Bond Work Index by Minerals

This Table of Ball Mill Bond Work Index of Minerals is a summary as tested on ‘around the world sample’. You can find the SG of each mineral samples on the other table. Source 1: Table of materials reported by Fred Bond Source 2: Outokumpu, The science of comminution Source 3: Equipment and pipelines Source 4: […]

Storage of Polymers

Storage of Solution polymers that are shipped in bulk, tote bins or in plastic drums. Solution polymers should be stored between 35º and 105°F and protected from freezing. If freezing occurs, the product should be warmed to 40º – 90°F and agitated prior to subsequent use. Product rotation is recommended to avoid prolonged storage times. […]

Dry Polymers

Dry polymers are typically made down to 0.25% solutions by adding 0.5 grams of polymer to 200 mLs of water. Use the same water for laboratory solution preparation that will be used to prepare samples in actual plant situation. The recommended mixers for dry polymer are magnetic stirrer (with large 2 inch magnet), overhead mixer, […]

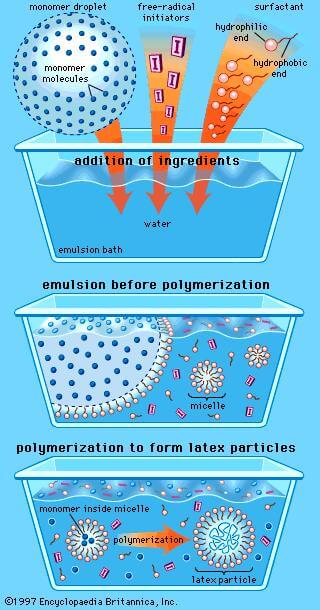

Emulsion Polymers -Mixing Procedure

Emulsion polymers are polymer in oil emulsions and are designed to “break” out of this emulsion into a water solution at 0.5 to 1.0% concentration. If water is allowed to get into the bulk storage tank, either by backing up in the feed line or by condensation, gels will form. They may take the […]

Preparation of Solution Polymers

Here is a Procedure for the Preparation of Solution Polymers: Solution polymers can be made down to any convenient concentration for laboratory testing. Suggested solution concentrations should be based on the expected dosage, ie: For raw water clarification 0.05 to 0.10% or for use in sludge dewatering at 1.0 to 5.0%. Use the same water for […]

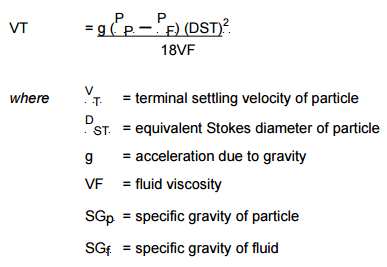

Beaker Decantation Method: Classify Particles by Settling

This method for Beaker decantation is a technique used to separate a mineral sample into two size fractions according to the differences in settling velocities of the particles. It is a technique which can be used to accurately split a sample at a pre-determined cut size but has some disadvantages in that it is a time consuming method […]

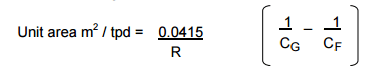

Settling and Thickening Test Procedure

The choice of Settling and Thickening test method and procedure depends to some extent upon the temperature of the pulp, its flocculating characteristics, the required supernatant clarity, and the equipment available. The Long Tube Method may be used for all materials which settle without a clearly defined interface. However, where the feed in question is well flocculated, either […]

Flocculation Test Procedure

A Flocculation Test Procedure is used to determine how much Flocculants need be added to solids in suspension (slurry or pulp) to cause the individual particles to collect in the form of flocs. The formation of flocs aids in improved settling rates, better overhead clarity and/or faster filtration rates. There are three main methods for achieving aggregation of […]

Cyclosizer

A cyclosizer, in principle, is an “old sizing machine” allowing size analysis of sub-sieve size (-38 micron). One of the most widely used methods of sub-sieve sizing in modern mineral-processing laboratories is the Warman Cyclosizer which is extensively used for routine testing and plant control in the size range 8 – 38 micron for minerals of specific gravity similar […]

Determination of Lead by Titration

This titration method lets you determine what your lead (Pb) assay contain is: Volume of the solution before boiling is 65 cc. Water and 10 cc H2SO4. Boil gently 5 minutes. Filter hot at approximately 93°C or cold at 23ºC. Ethyl alcohol added when required. No.2 munktell filter papers. Wash three times with cold water, […]