Bulk Density of Rod Mill Bars-Rods

How a Rod Mill Works

Recommended Rod Mill Bar Length

Ever asked what size/length rods (bars) you need for charging your rod mill? It depends on the rod mill diameter itself. To prevent most conditions leading to rod charge tangling, the generally recommended relationship of rod length to mill diameter Inside liners is 1.4 to 1.6. When this ratio becomes less than 1.25 the risk of […]

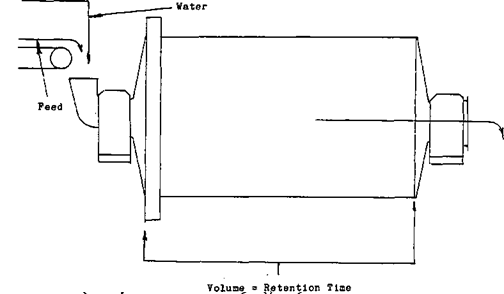

Effect of Water & Density on Grinding Mill

The Time that the ore spends in the grinding mill is called, RETENTION TIME. This is a very important variable, the longer the retention time, the more the ore comes in contact with the rods, the better and finer the grind becomes. To understand this important control it must be remembered that any volume that […]

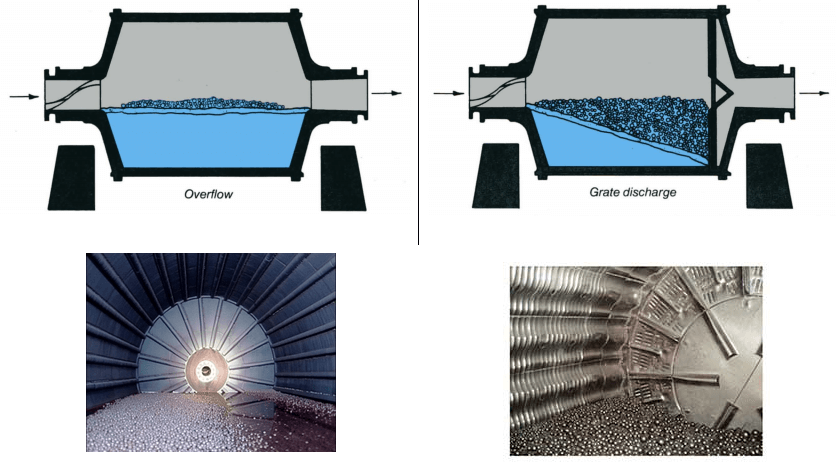

Overflow VS Grate Discharge Ball or Mill – Why Retrofit

Allow me to compare: Ball mills can be of the overflow or of the grate discharge type. Overflow discharge mills are used when a product with high specific surface is wanted, without any respect to the particle size distribution curve. Overflow discharge mills give a final product in an open circuit. Grate discharge mills are used when the […]

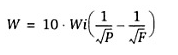

What Ore Testing is Required For Mill Selection

Beginners might ask what grinding test data is required in order to properly size a grinding mill. After the grind requirements are established, testing for the selection of comminution circuits and mill size can be initiated and can include the following: Primary Autogenous Media Competency Primary Autogenous and Semi-Autogenous Pilot Plant Secondary Autogenous (Pebble) Testing […]