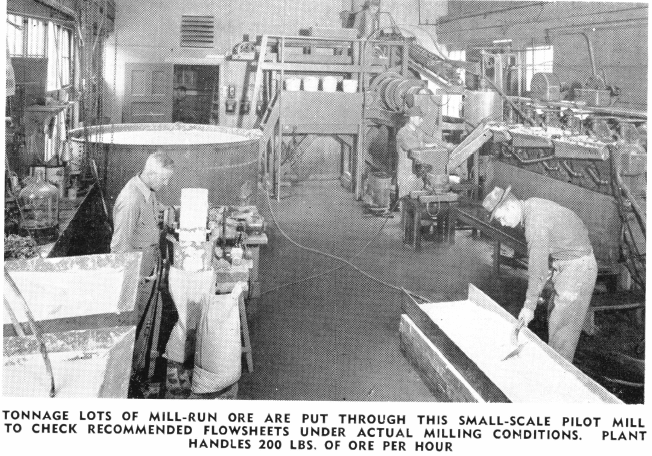

The Metallurgical pilot concentration plant is completely equipped with gravity and flotation units sufficient to provide for practically any flowsheet employing these methods of concentration. All equipment for the pilot concentration plant is set for continuous operation. Due to movable launders, pumps, and flow pipes, extreme flexibility is available.

Crushing: Ore is prepared in the crushing, screening, and sampling section.

Grinding: Positive control of feed rate to the grinding section is secured by evenly distributing weighed portions of the crushed ore on the feed belt of a 9″x 9′ Belt Ore Feeder which can be run to deliver into a 16″x 16″ Ball Mill or to deliver into special equipment.

The ball mill, which has a conventional capacity of 200 pounds of quartz ore per hour, can be doubled in length to give added capacity. It operates in closed circuit with a 9″ Rotary Classifier which is adjustable as to slope and speed of the spiral. The ball mill discharges into either a No. 7 Unit Flotation Cell, a 4″x 6″ Mineral Jig, or other desired apparatus; the circuit is closed by a Vertical Sand Pump.

Flotation: The classifier overflow may pass to one of three 18″ Conditioners. Gas burners are placed under the conditioners so that the pulp temperatures may be elevated when required; this is important in many instances where tests are being conducted under actual plant conditions so that results in pilot plant will closely approximate actual commercial operations.

One pilot plant test was conducted with ice in the constant head tank so that the temperature of the pulp was maintained at below normal to conform to conditions expected in the operation of the proposed mill which was constructed entirely underground.

The flow then passes through two separate banks of No. 7 “Sub- A” Flotation Machines of six cells each with conditioners between each bank. There is also provided one bank of four No. 5 “Sub-A” Flotation Cells mounted on a portable frame for special cleaning operations; an additional 6¬cell No. 7 “Sub-A” Flotation Machine is also available. Flotation concentrates can be pumped to either the pan filters or filtered direct from the cells by the portable rotary drum filter.

The flotation tailing is delivered to a 54″x 18″ Wilfley Table by a Vertical Sand Pump and from there to the tailing thickener, in which the pulp is thickened and the solids sampled or discarded and overflow drained off to waste or recirculated as may be desired. Flows of middling products can be returned to any desired point in the circuit by Vertical Sand Pumps.

Auxiliary Equipment: Other auxiliary equipment includes 4″x 6″ Mineral Jigs, Unit Flotation Cells, a Hydroclassifier, a 4′ Spiral Rake Thickener, an 8″x 18″ Rotary Vacuum Filter, two 3’x 3′ Pan Filters with vacuum pumps and receivers, and a 10’x 6′ bolted steel tailing disposal tank. All machines are driven by individual electric motors except in the flotation sections where one motor drives two cells.

Drying: Concentrates can be dried where necessary by steel pan driers which are coated with a cement made by mixing asbestos fiber with sodium silicate and heated by gas burners. The coating of asbestos and sodium silicate becomes very hard upon heating and prevents contamination of the concentrates with iron oxide which is often detrimental in the case of some non- metallic products, desired for the purpose of conducting further tests for the manufacture of finished products.

Water: Water for the entire plant is supplied through two separate pipelines. One line is fed directly from the city water main so that city water pressure is available where needed. The other line which is connected to all machines is fed from a 5’x 5′ Bolted Steel Head Tank so that constant pressure enables a close control of water supply. Filter receivers and tailing disposal tank are also connected to the head tank by pump and pipeline to permit the re-use of mill pulp water.

Reagents: Flotation reagents for the continuous test plant are ordinarily fed by Portable Wet Reagent Feeders. Where exceptionally small quantities of certain reagents are required, such as pine oil, cresylic acids, etc., a special attachment has been perfected for the Portable Wet Reagent Feeder so that quantities as low as one drop in two minutes can be continuously and accurately fed to the cells.

Controls: Plant control apparatus available include Pulp Density Scales and Buckets, Beckman pH Meter, one binocular microscope, one petrographic microscope, and one ultraviolet lamp.

Analytical Laboratory

The analytical laboratory is equipped to afford all ordinary chemical analyses of materials and is used primarily in making analyses of products from preliminary investigations. Analyses of final test products which are included in the test report of the complete work are made by disinterested commercial assayers and chemists.

This section is provided with electric and gas hot plates, fume hood, electric furnace, analytical and button balances, gold balance, filtering racks, and a complete stock of analytical chemicals.