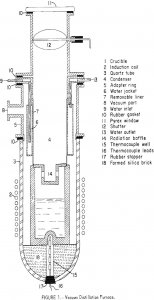

Vacuum Distillation – Remove Volatile Metals

Table of ContentsVolatility of Metals and AlloysExperimental ProcedureExperiments on Comparative Behavior of Volatile MetalsDistillation of Cadmium from Lead and TinDistillation of Magnesium from Lead and

Table of ContentsVolatility of Metals and AlloysExperimental ProcedureExperiments on Comparative Behavior of Volatile MetalsDistillation of Cadmium from Lead and TinDistillation of Magnesium from Lead and

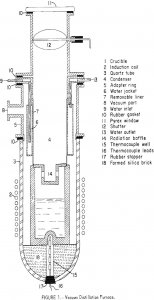

Table of ContentsTheoretical AspectsReduction of Titanium Tetrachloride With SodiumHigh-Surface SodiumPractical ConsiderationsApparatusTitanium Tetrachloride SystemSodium SystemReactorHeat-Exchange SystemProduct-Discharge MechanismMaterials for ReductionExperimental ProcedureAnalytical MethodsResults and Discussion This investigation has

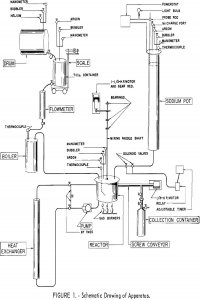

Table of ContentsRates of AbsorptionEquilibrium DataSolubility of Gases in Hot Carbonate SolutionCorrosionPilot-Plant OperationEquipmentPilot-Plant ResultsTypical Data With Various Feed GasesDegree of Removal of Carbon Dioxide and

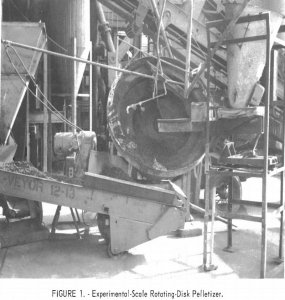

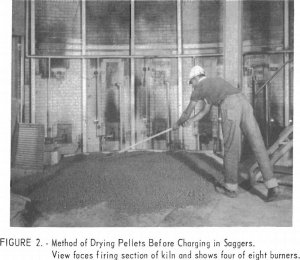

Table of ContentsPreparation of PelletsExperimental Smelting OperationExperimental ResultsIndustrial Application Fines and concentrates must be consolidated or agglomerated into larger masses before they can be smelted

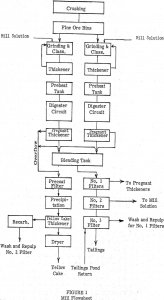

Table of ContentsMill DescriptionAir Oxidation StudiesStudy of Chemical OxidantsOxidation-Reduction Theory for Alkaline PulpsResults Obtained in First Plant Tests Early studies in the carbonate leaching of

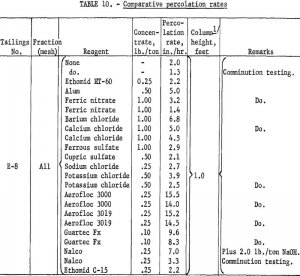

Table of ContentsLaboratory Investigation of Fl0cculantsGeneral Discussion of FlocculationDefinitionsNature of the TailingsExperimental ProcedureSelection of ReagentsDiscussion of Test ResultsSettling and Percolation RatesEffects of Flocculation and Agitation

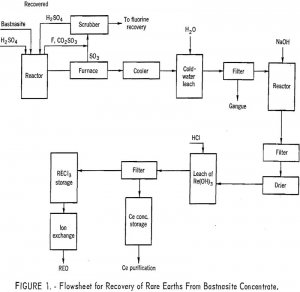

Table of ContentsSource of Bastnasite ConcentrateChemical Processing of Bastnasite ConcentrateChemical Separation of Rare-Earth Elements from BastnasiteIon-Exchange SeparationsSolvent-Extraction Separations A bastnasite concentrate, containing about 60 percent

Table of ContentsLaboratory and Pilot-Plant InvestigationsLaboratory Tests on Production of Nickel Metal from Nickel OxidePreliminary Reduction TestsSagger EvaluationOperating ConditionsPreliminary Melting TestsPilot-Plant Production of Sponge NickelEquipment

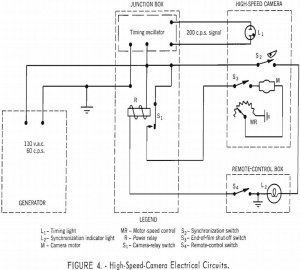

Table of ContentsDescription of EquipmentHigh-Speed Photographic EquipmentProjection EquipmentTheory of MeasurementsCorrection for Camera OrientationGravity EffectsScale FactorTime of Initial MovementField Operating ProcedureAnalysis Procedure The breaking of rock

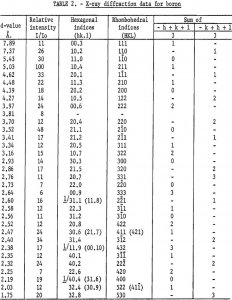

Table of ContentsChemical and Spectrographic AnalysesX-ray TechniqueEquipmentDataAnalysis of DataIndexingConversion of Rhombohedral IndicesVerification of Results In connection with its continuing studies of the characteristics of alloys