How to Use Heat to Separate Copper from Steel Scrap

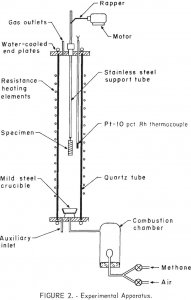

We initiated a program was concerned with the utilization and disposal of steel scrap, as the pollution and unsightliness caused by the accumulation of steel

We initiated a program was concerned with the utilization and disposal of steel scrap, as the pollution and unsightliness caused by the accumulation of steel

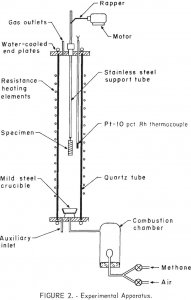

Cells were designed and successfully operated on a laboratory scale for electrowinning high-purity neodymium, praseodymium, and didymium, as well as the higher melting-point metals, gadolinium,

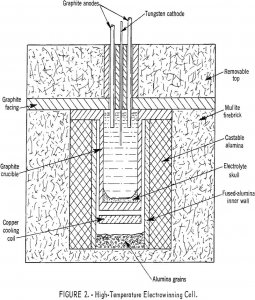

The electrolytic separation of nickel and cobalt by electrorefining in a molten salt electrolyte was shown to be technically feasible. Nickel-cobalt alloys containing up to

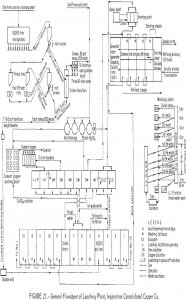

Copper hydrometallurgy the leaching of siliceous low-grade copper-bearing ores and waste rock that cannot be processed economically by milling and concentrating is an important low-cost

For the past two decades, about one-third of the copper consumed in the United States has been imported. In order to meet the Nation’s demand,

Because of its poisonous qualities, the arsenic which is sometimes present in coal and in the atmospheric dust resulting from coal combustion can present a

In contact-angle research, 10 of the 17 surfactants evaluated proved to be collectors for Chrysoberyl Flotation. With eight of the nine surfactants evaluated as collectors,

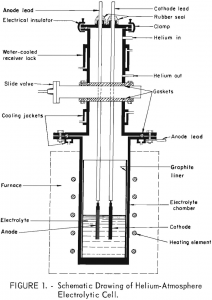

The first large-scale leaching and precipitation of copper was probably at Rio Tinto in Spain about 1752. The method employed comprised open-air water leaching of

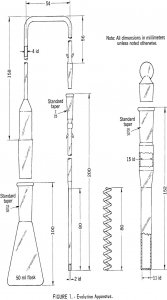

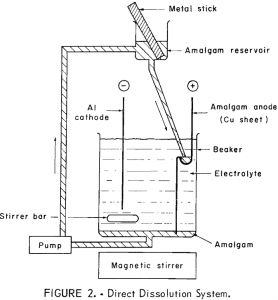

The following conclusions are drawn from the results of the laboratory tests of amalgam electrorefining of zinc and tin: Amalgam electrorefining is a method by

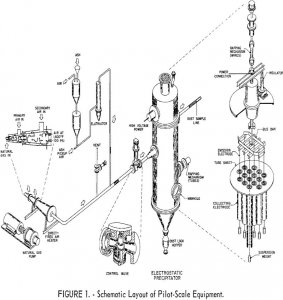

Industrial precipitators utilizing negative corona operate at maximum voltage to attain highest efficiency in removing finely divided particles from gas streams. Usage, however, is limited