Cone Crushing, Rod Milling and Ball Milling Laboratory Testing

The two largest cost components in comminution circuits are energy consumption and metal wear which, for cone crushing, rod milling and ball milling, can be

The two largest cost components in comminution circuits are energy consumption and metal wear which, for cone crushing, rod milling and ball milling, can be

Careful studies of the fundamentals of chromite flotation have been made recently in the United States and in Poland. Palmer (1972), Palmer, Fuerstenau and Aplan

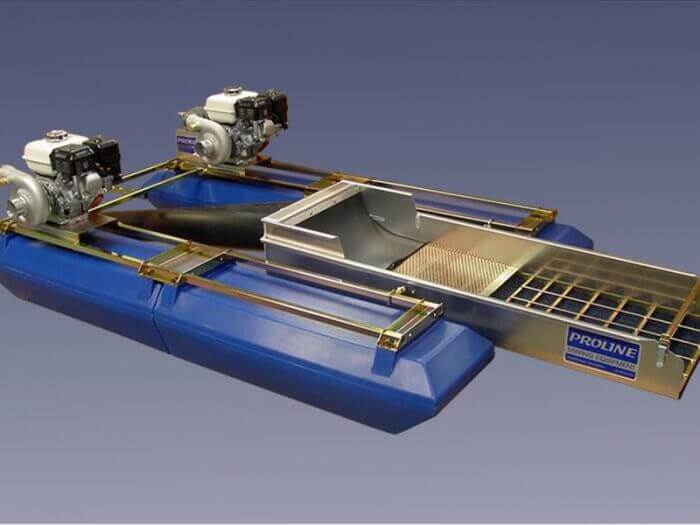

With regards to diamond dredges and dredging, the kings of the 1970s were Consolidated Diamond Mines and Marine Diamond Corp. both parts of the famous

For many years, the diecasting process has been employed by the nonferrous foundry industry. In this process, castings are produced by forcing molten metal under

The important of crushing your ore and rock fine and properly is often forgotten. The finer you crush, the higher your ball mill tonnage and

The use of induction heating as an alternative to gas or oil fired heating for the fire, refining of precious metals is attractive for several

Sslurry at a rate of approximately 3.785 cu. m. per minute (1,000 GPM) is placed in contact with activated carbon. A simplified flow-sheet of the

The Knelson Concentrator relies on an enhanced gravitational force together with fluidization process to recover even very micron sized particles. First water is injected into the

The manufacture and use of nickel-cadmium alkaline batteries began to grow in the late 1950’s. During the period from 1966 to 1971, approximately 3 pct

Rock splitting utilizes a tensional force to crack the rock. This is achieved by inserting a split steel shank in a drillhole and driving a