Sulphuric Acid Parting of Gold & Silver

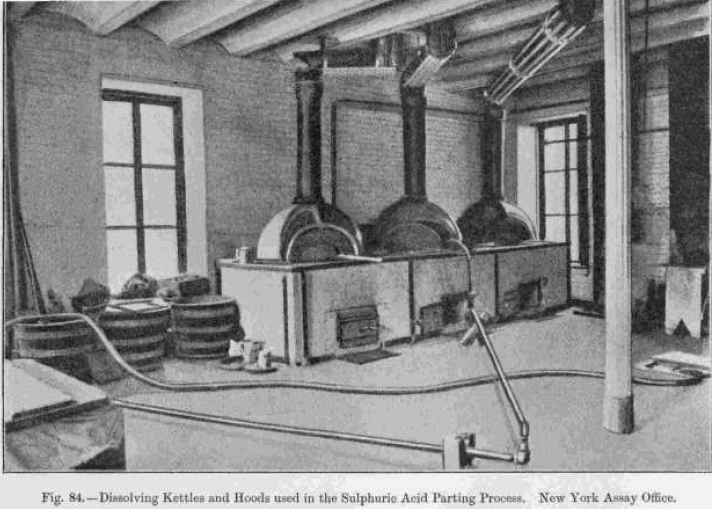

This process has now, in the majority of refineries, superseded the nitric acid method, which is much more expensive, owing to the higher cost of

This process has now, in the majority of refineries, superseded the nitric acid method, which is much more expensive, owing to the higher cost of

The silver chloride is then reduced in lead-lined tanks by means of granulated zinc and water acidulated with sulphuric acid. Thirty-three pounds of commercial granulated

The gold to be parted must be approximately free from base metals, particularly from those which are not soluble in nitric acid, such as tin,

Parting is the separation of silver from gold and a process during which the base metals are separated from both, but, as the presence of

By whatever process gold may have been extracted from its ores, it is necessary to melt the crude bullion and cast it into bars so

The operation of refining by one of the methods described above is necessary before gold can be exactly valued. When base metals other than copper

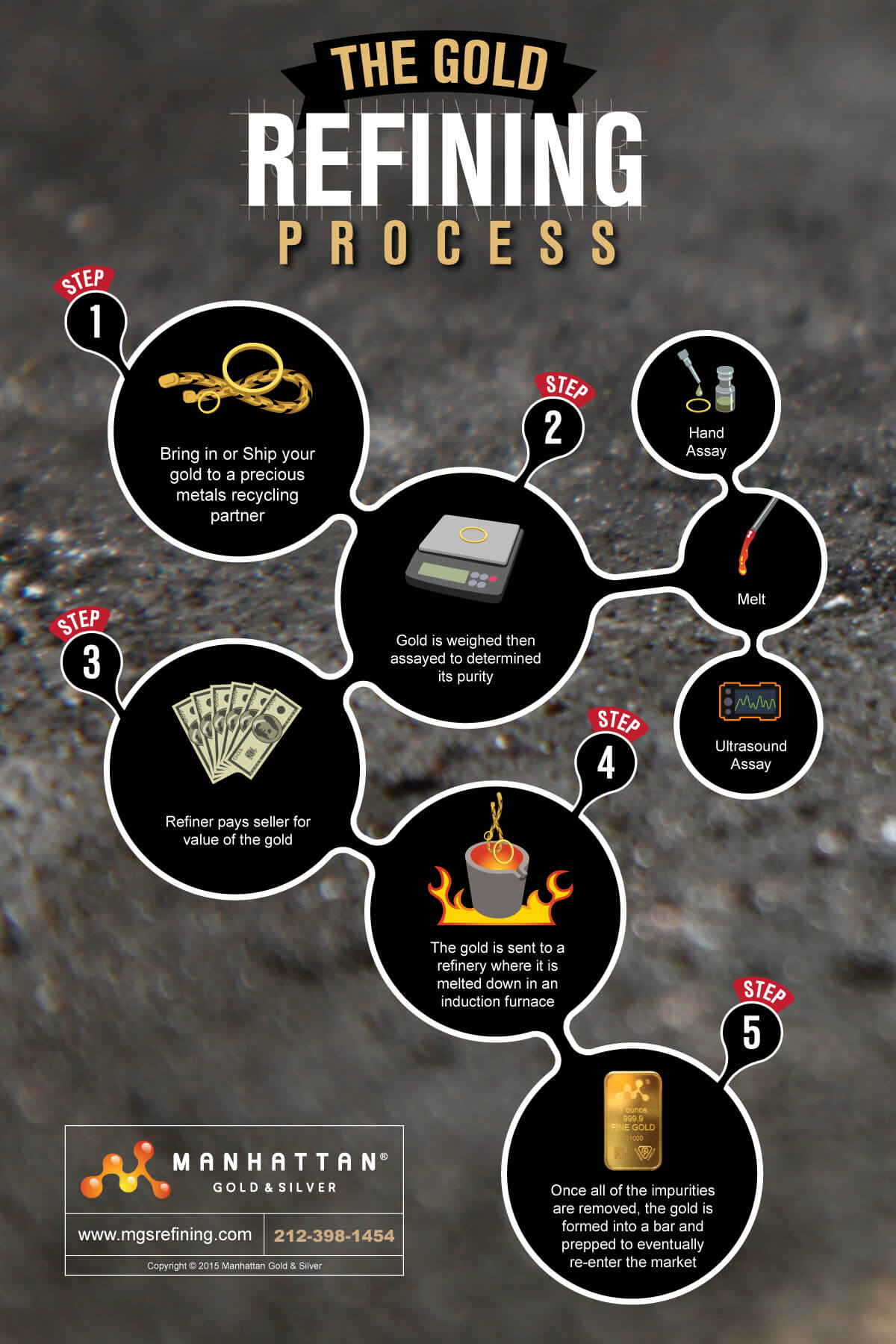

The processes used for Gold Refining are as follows: Volatilisation. Oxidation (a) by air blowing or roasting. (b) by “ bessemerising” (c) by nitre. (d)

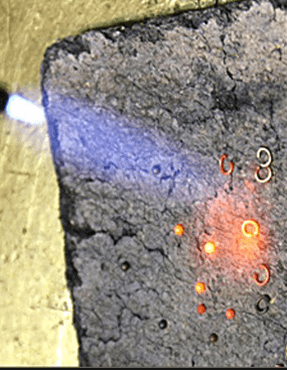

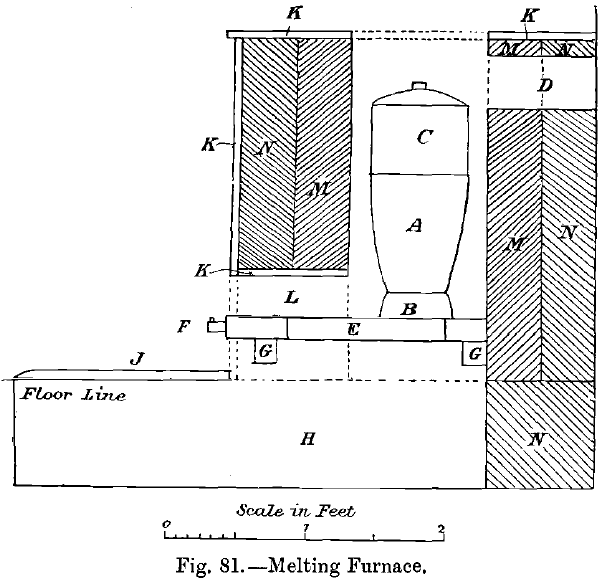

The furnace used for melting gold bullion is of simple construction. It may be round or square, with walls consisting of an outer layer of

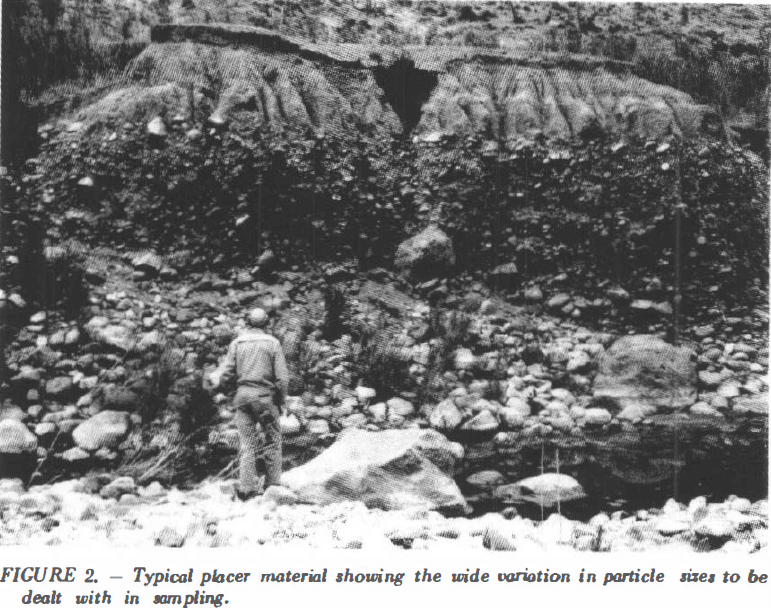

Acquiring a representative gold sample is seldom easy and in almost all cases sample results need a large measure of interpretation. Some of the underlying reasons

There are two kinds of sample salting: intentional and innocent. Intentional salting can be defined as the surreptitious addition of valuable material to a sample