Plattner Gold Chlorination Process

The use of chlorine as an agent for the extraction of gold from ores was first suggested by Dr. John Percy, F.R.S., at the Swansea

The use of chlorine as an agent for the extraction of gold from ores was first suggested by Dr. John Percy, F.R.S., at the Swansea

Ball Mills and stirred mills are applied across a wide range of applications, but for each ore there is optimum efficient range. The figure to

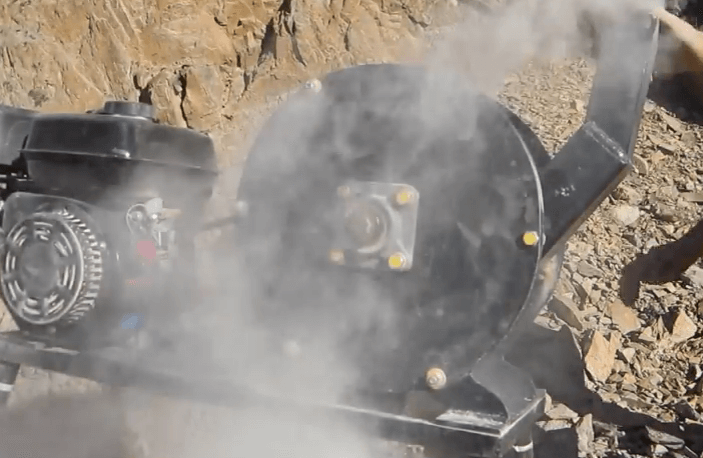

The first step in minerals beneficiation of an ore is normally crushing which has been defined “as the operations required to reduce run-of-mine ore to

A Chain Mill is a total amateur’s tool for “crushing or grinding” rock. It is a set of chains attached directly at the end of

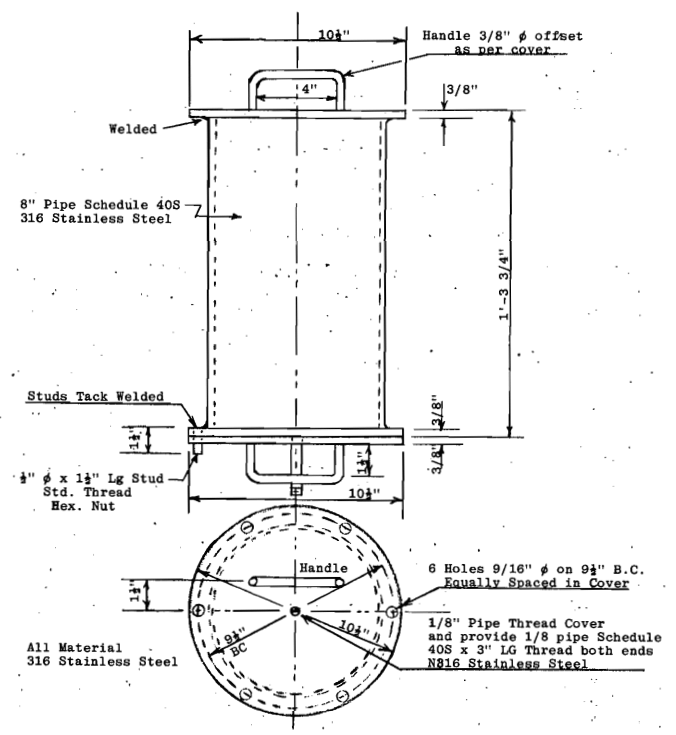

By this drawing, it is suggested that a typical homemade laboratory rod mill or ball mill might be fabricated from 20 cm (8 inches) diameter

Metallurgical testing and corresponding flowsheet development programs involve acquisition of certain basic information, a laboratory testing phase, the preparation of reports and, finally, flowsheet development.

In metallurgy, the operation of roasting, as a preliminary to chlorination, has for its object the expulsion of the sulphur, arsenic, antimony and other volatile

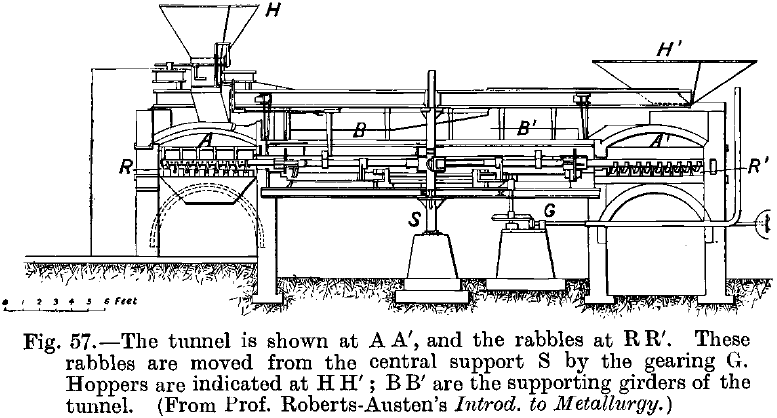

The furnaces which have been designed with the object of saving the labour necessary to work the reverberatory furnaces may be divided into four classes:

The construction of the ordinary reverberatory furnace is too well known to need detailed description here. It consists of a vaulted chamber, containing the ore;

Tube Mills consist of revolving cylinders, the interior of which is perfectly plain. They contain a number of hard balls. They differ from ball mills essentially