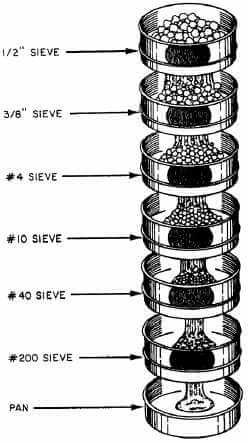

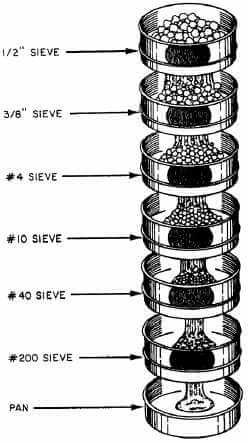

How to Perform a Sieve Analysis

For particle size analysis, the test sieve remains a cost effective and precise measuring instrument for dry non-agglomerated particles. Test sieve analysis is widely used

For particle size analysis, the test sieve remains a cost effective and precise measuring instrument for dry non-agglomerated particles. Test sieve analysis is widely used

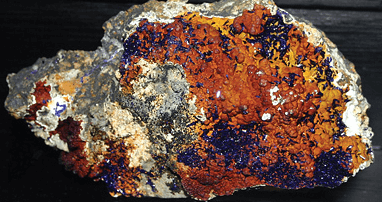

In the case of many complex gold and silver ores roasting before cyanidation is essential if satisfactory extraction of the precious metals is to be

Where gold is associated with arsenic, antimony, tellurium, and certain other minerals, it is often only partly soluble in cyanide solution. The difficulty is usually

Cyanidation as applied to ordinary gold and silver ores is a relatively simple process. When cyanicides {cyanide-consuming elements) are encountered in small amounts in the

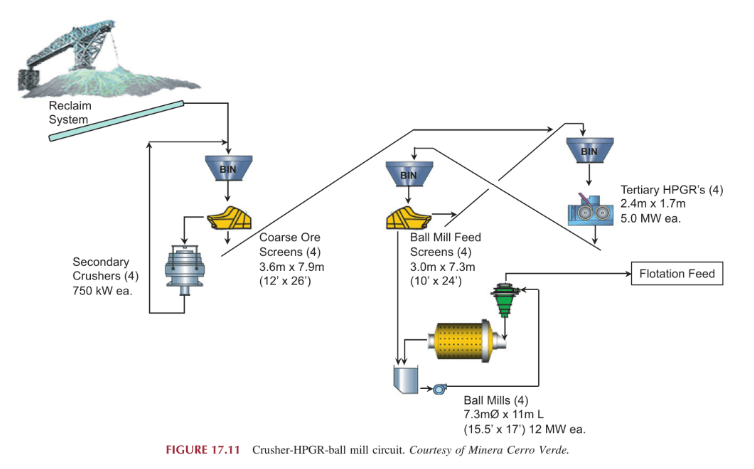

HPGR or high-pressure grinding rolls have made broad advances into nonferrous metal mining. The technology is now widely viewed as a primary milling alternative, and there

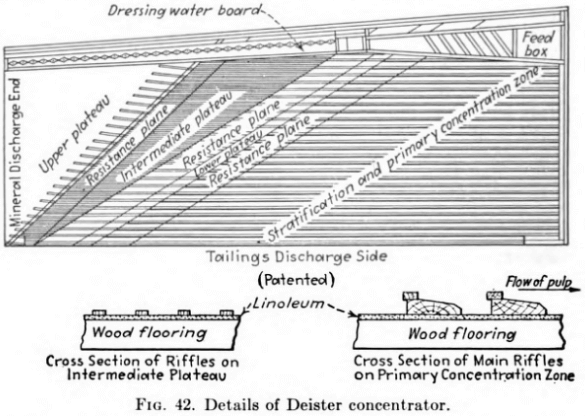

Overflow from the grinding mill runs over Gold Shaker Tables which are flat and smooth and made of a fibrous wood known as “yolombo.” They are arranged

Though the gold recovery methods previously discussed usually catch the coarser particles of sulphides in the ore and thus indirectly recover some of the gold

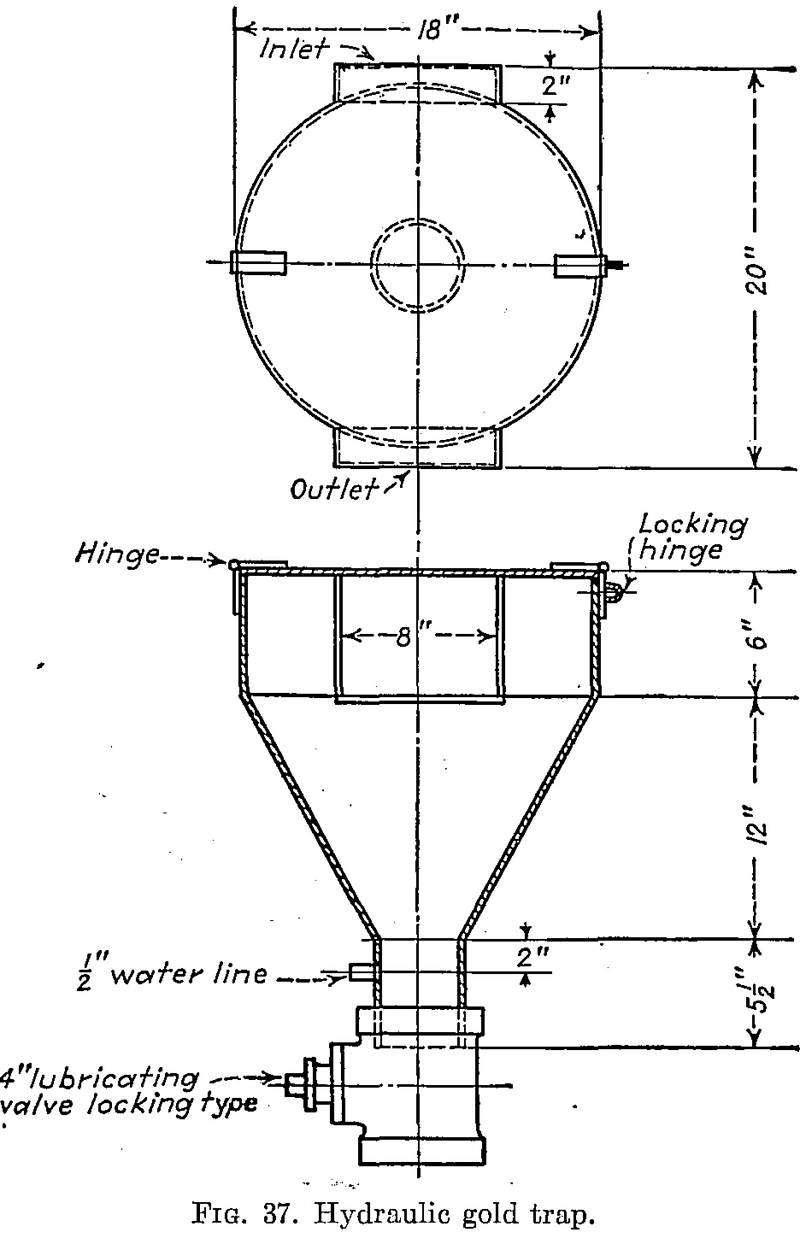

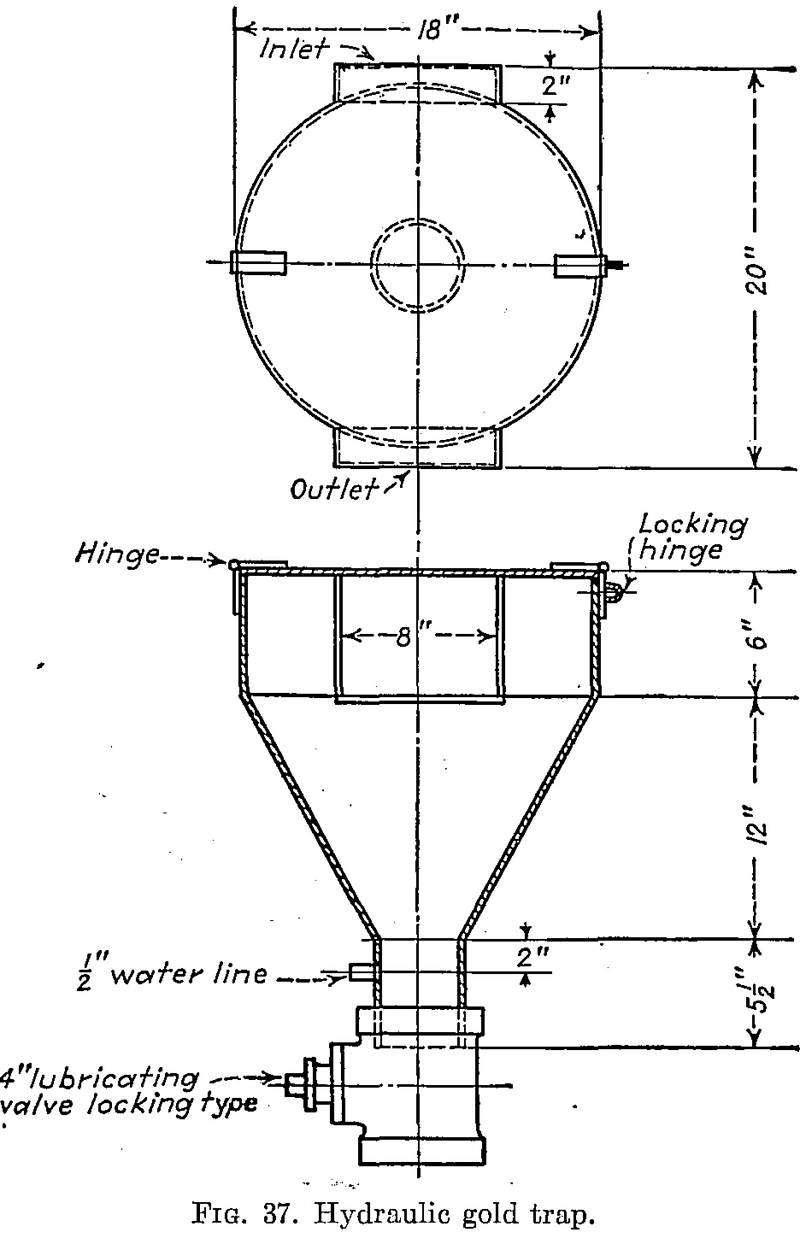

Regardless of subsequent treatment, it is considered best to recover free gold as early and as completely as possible in the flow of pulp. Gravity

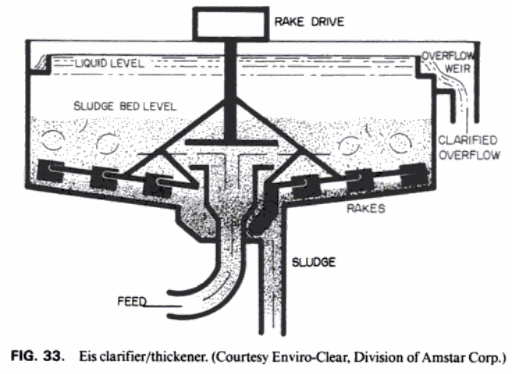

There are two basic types of high rate thickener units: Lamina or tube settlers and solids recirculation units Lamina Thickeners They contain space-cutting baffles that

Slime treatment, as commonly used by metallurgical engineers, includes thickening, agitation, and filtering and as applied, to cyanidation also includes washing by continuous countercurrent decantation