SAG Mill Liner Design

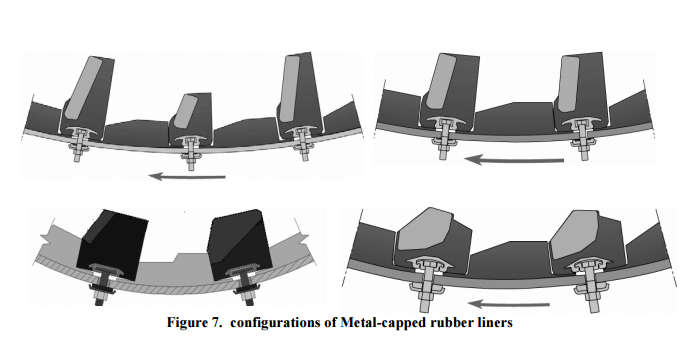

To a more significant degree than in other comminution devices, SAG Mill Liner Design and Configuration can have a substantial effect mill performance. In general terms,

To a more significant degree than in other comminution devices, SAG Mill Liner Design and Configuration can have a substantial effect mill performance. In general terms,

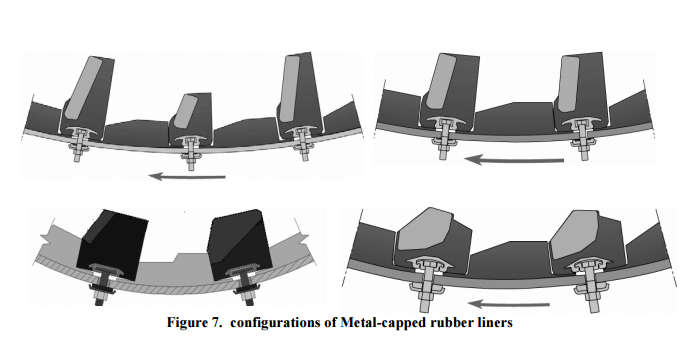

AG and SAG mills are now the primary unit operation for the majority of large grinding circuits, and form the basis for a variety of

Save Time and Login using email: flotation@flotation.com and password: flotation Save Time and Login using email: flotation@flotation.com and password: flotation

Save Time and Login using email: flotation@flotation.com and password: flotation Save Time and Login using email: flotation@flotation.com and password: flotation

Save Time and Login using email: flotation@flotation.com and password: flotation Save Time and Login using email: flotation@flotation.com and password: flotation

Save Time and Login using email: flotation@flotation.com and password: flotation Save Time and Login using email: flotation@flotation.com and password: flotation

Save Time and Login using email: flotation@flotation.com and password: flotation Save Time and Login using email: flotation@flotation.com and password: flotation

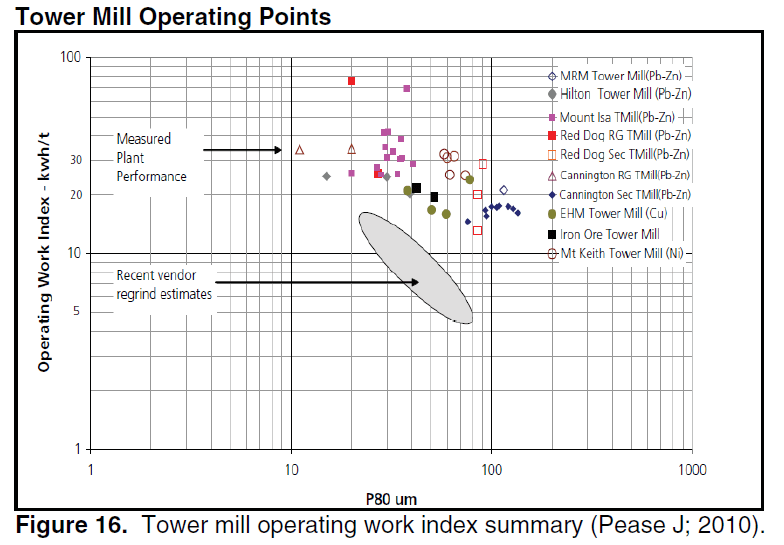

The principal method of grinding in a Tower mill is attrition (scrubbing of particles off material being ground), with the possibility of some shearing and

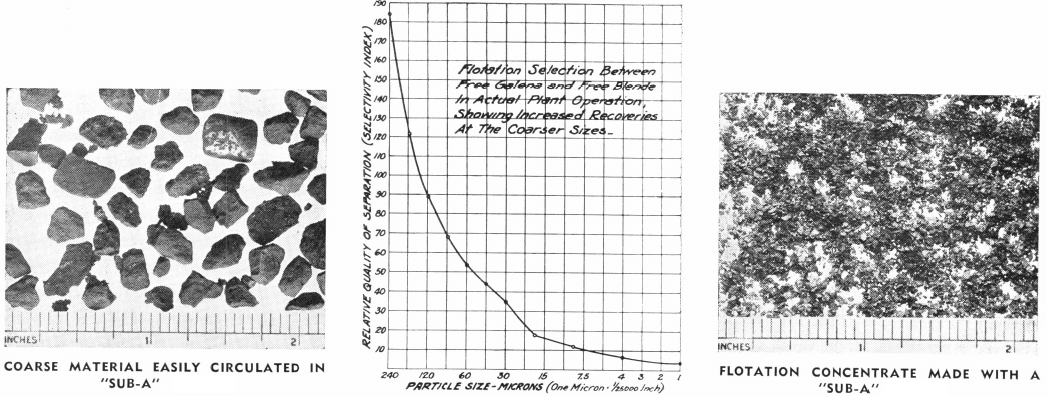

Metallurgical Recovery, which consists of the percentage of mineral saved, must not be confused with economic recovery which covers the percentage of the gross value

In The Days of gravity concentration, the art of ore dressing developed on the cardinal principle of saving the values at as coarse a size