Mineral Processing and Extractive Metallurgy

The first objective of Mineral Processing and Extractive Metallurgy is to remove the Mineral as soon as freed and as coarse as possible” is the

The first objective of Mineral Processing and Extractive Metallurgy is to remove the Mineral as soon as freed and as coarse as possible” is the

Before the event of ore dressing, crude ores were shipped directly to the smelters, or the refineries, with the shipper paying the freight and treatment

The gold industry has been seeking alternative reagents for leaching gold from low-grade ores for the past 25 years. The cost and transport of cyanide,

The practice of thickening or clarification is usually carried out in decantation tanks employing gravity settling or sedimentation. These tanks are fitted with mechanical scrapers

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.

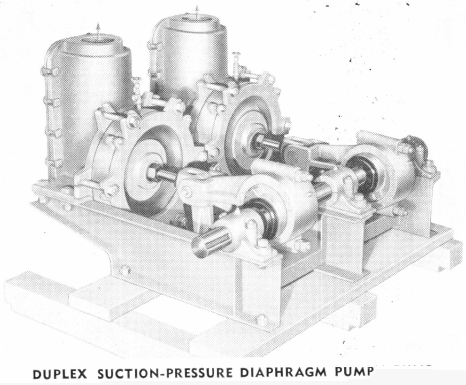

Suction-Pressure Diaphragm Pump Working Principle and Operations Each Suction-Pressure Diaphragm Pump consists essentially of a pump bowl, in a vertical position, with one rubber diaphragm on

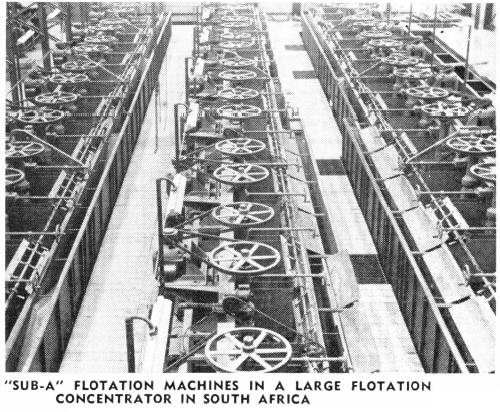

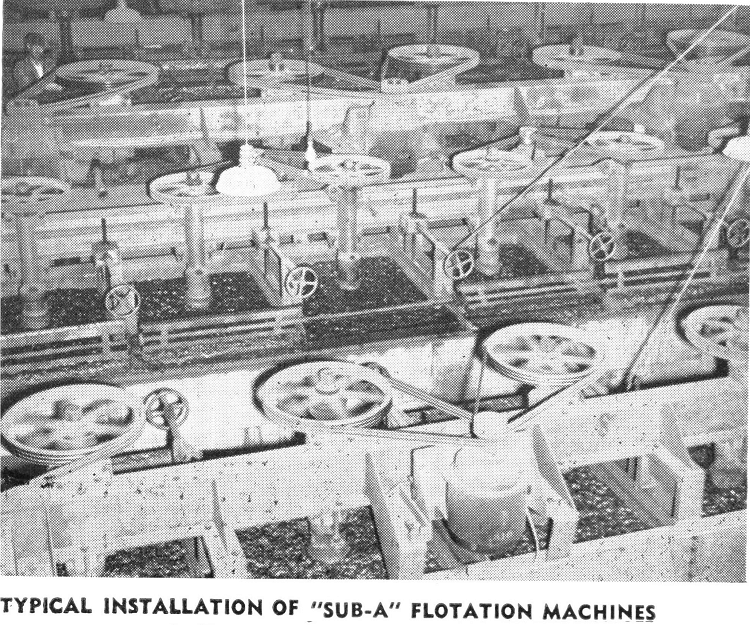

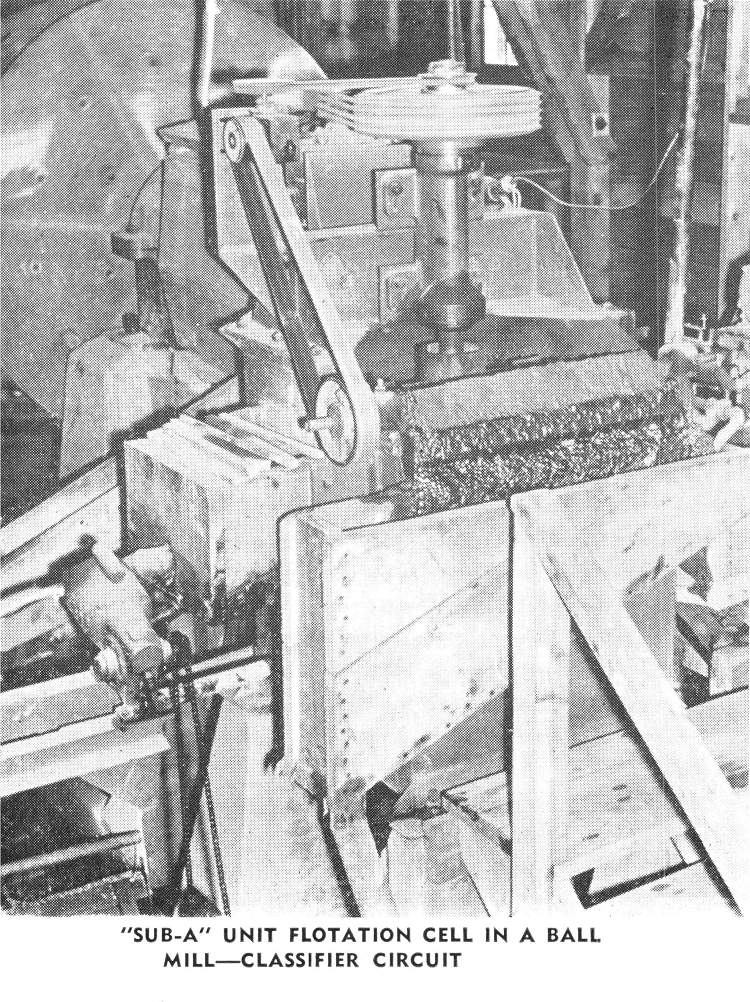

The flotation process and related flotation cells are widely used for treating metallic and nonmetallic ores and in addition, it is receiving an ever widening application

More profit can be earned by using the Flash Flotation Cell in the grinding Circuit. This machine has been designed especially for the recovery of