Chemical Smelting

Some of us who have been acquainted with the present methods of production of metals, and who have had an opportunity to witness the impact

Some of us who have been acquainted with the present methods of production of metals, and who have had an opportunity to witness the impact

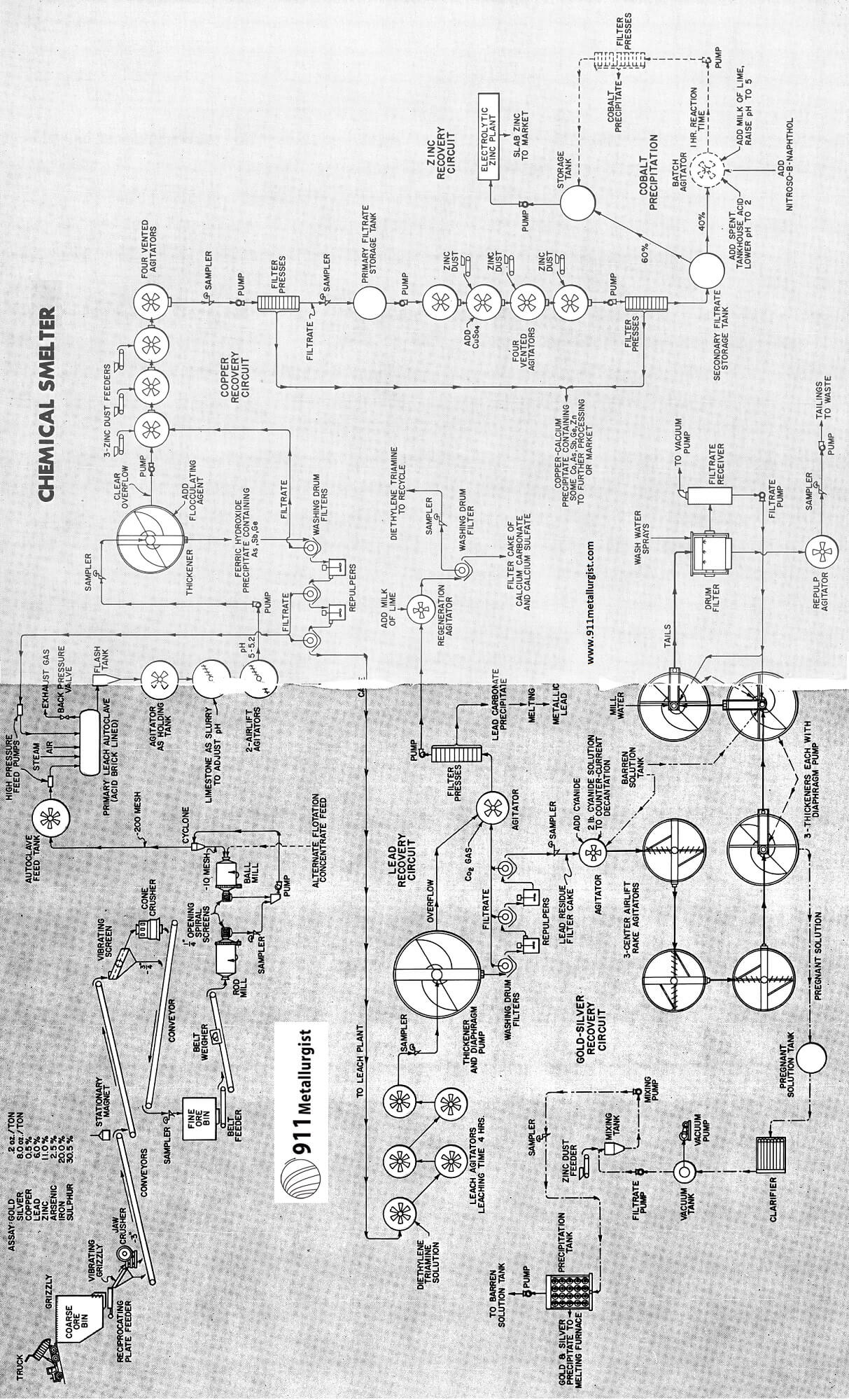

The treatment of complex silver cobalt ores occurring with antimony and arsenic require special metallurgical processing to produce concentrates most advantageous for smelting. Gravity concentration

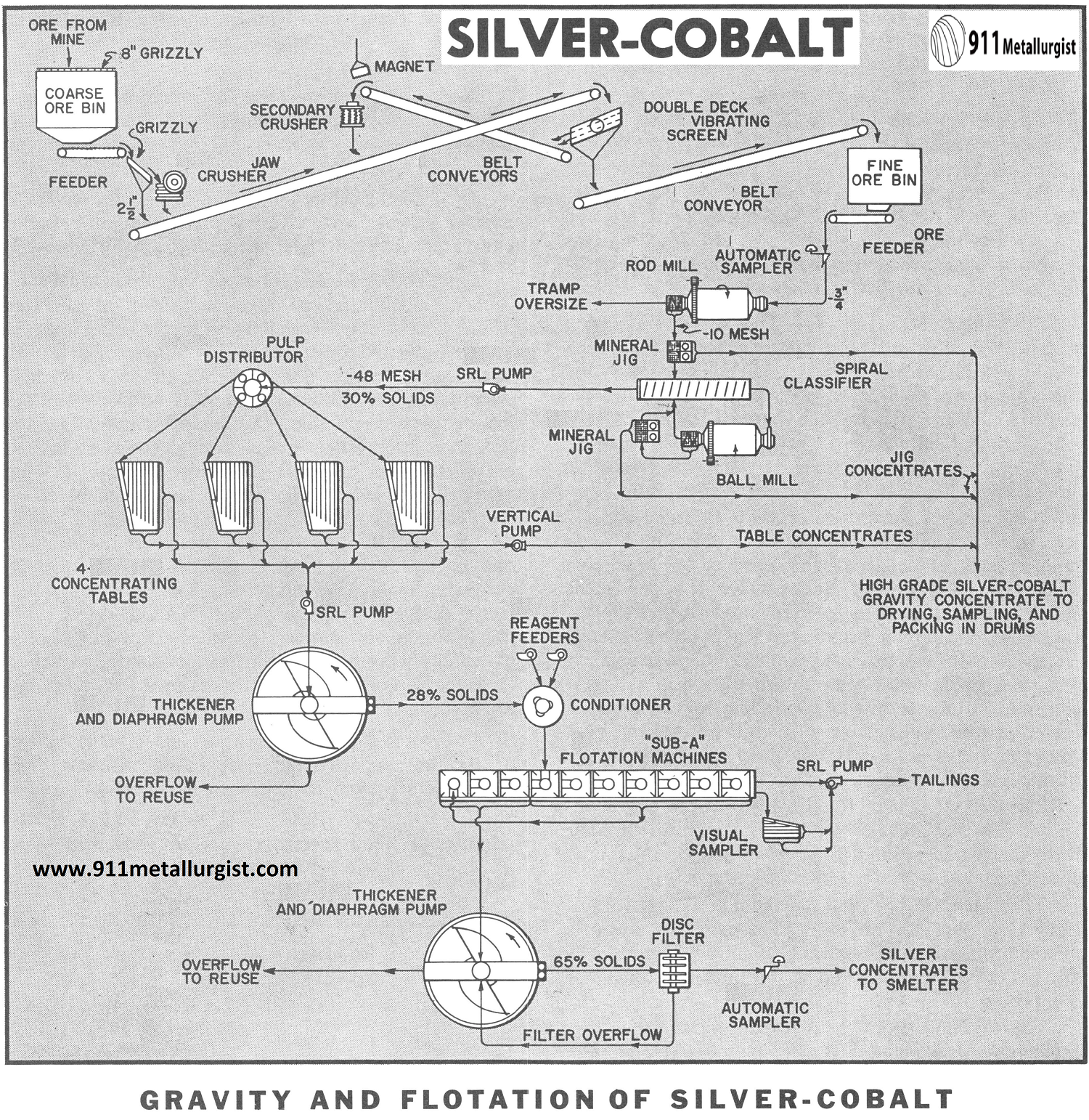

The processing of extensive pit run gravel in many instances employs a permanent or semi-permanent plant installation with a flexible system for movement of feed.

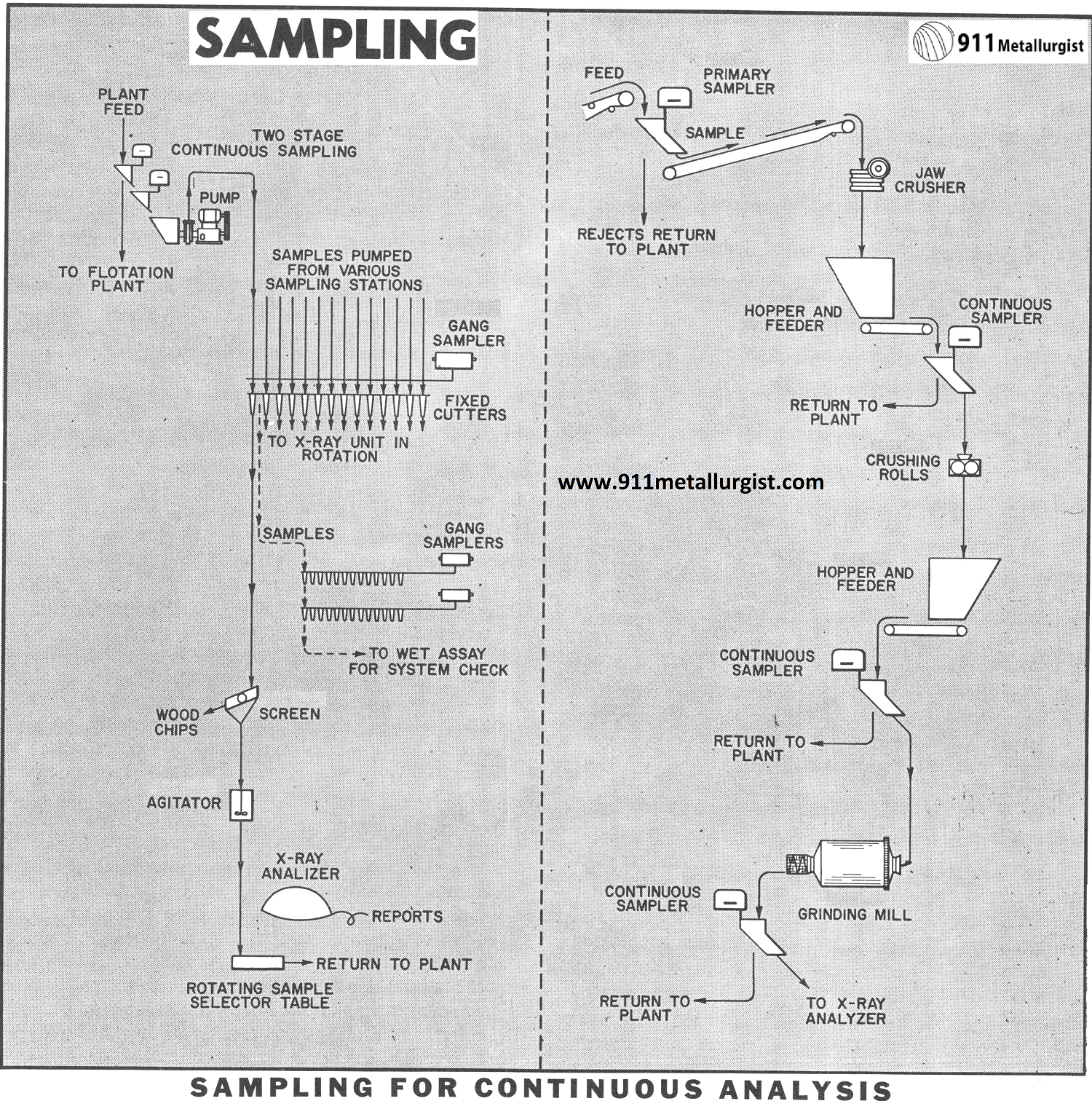

Development and use of on stream analysis for both wet and dry processes promises great advantages in processing and quality control. In many cases the

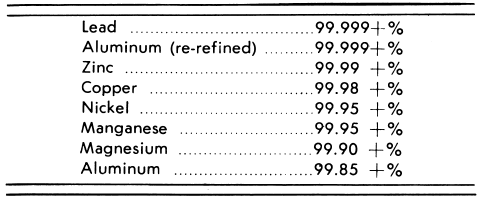

The list of pure non-ferrous metals so widely used in modern industry includes many that are produced by electrolytic means, such as copper, zinc, nickel,

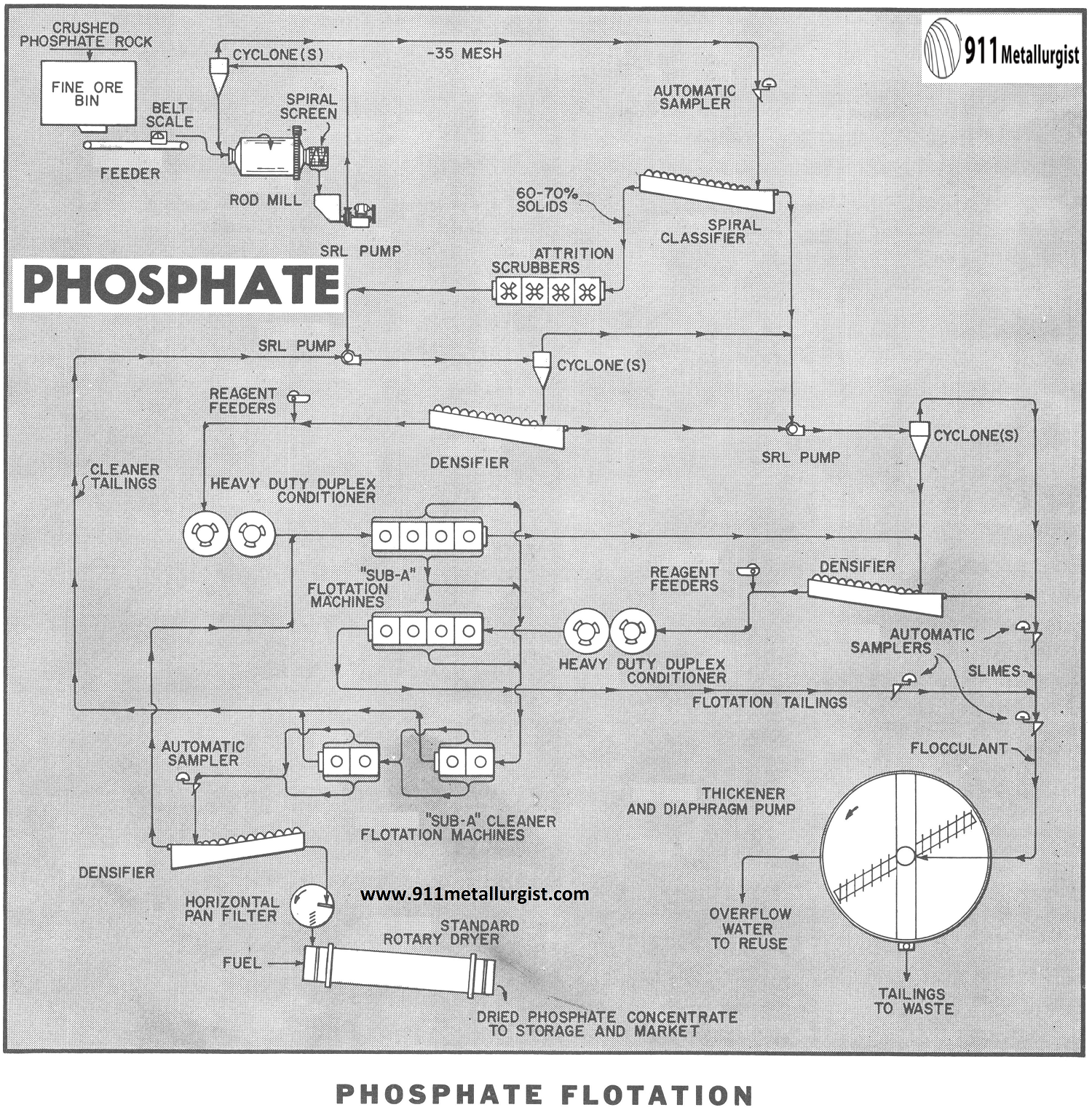

The phosphate-bearing formations in the West constitute relatively thick beds of phosphatic sandstones and shales that can be mined on a large scale employing open

The milling of talc, as is the case with many non-metallic minerals, until recently, has not received adequate technical consideration, for the talc industry has

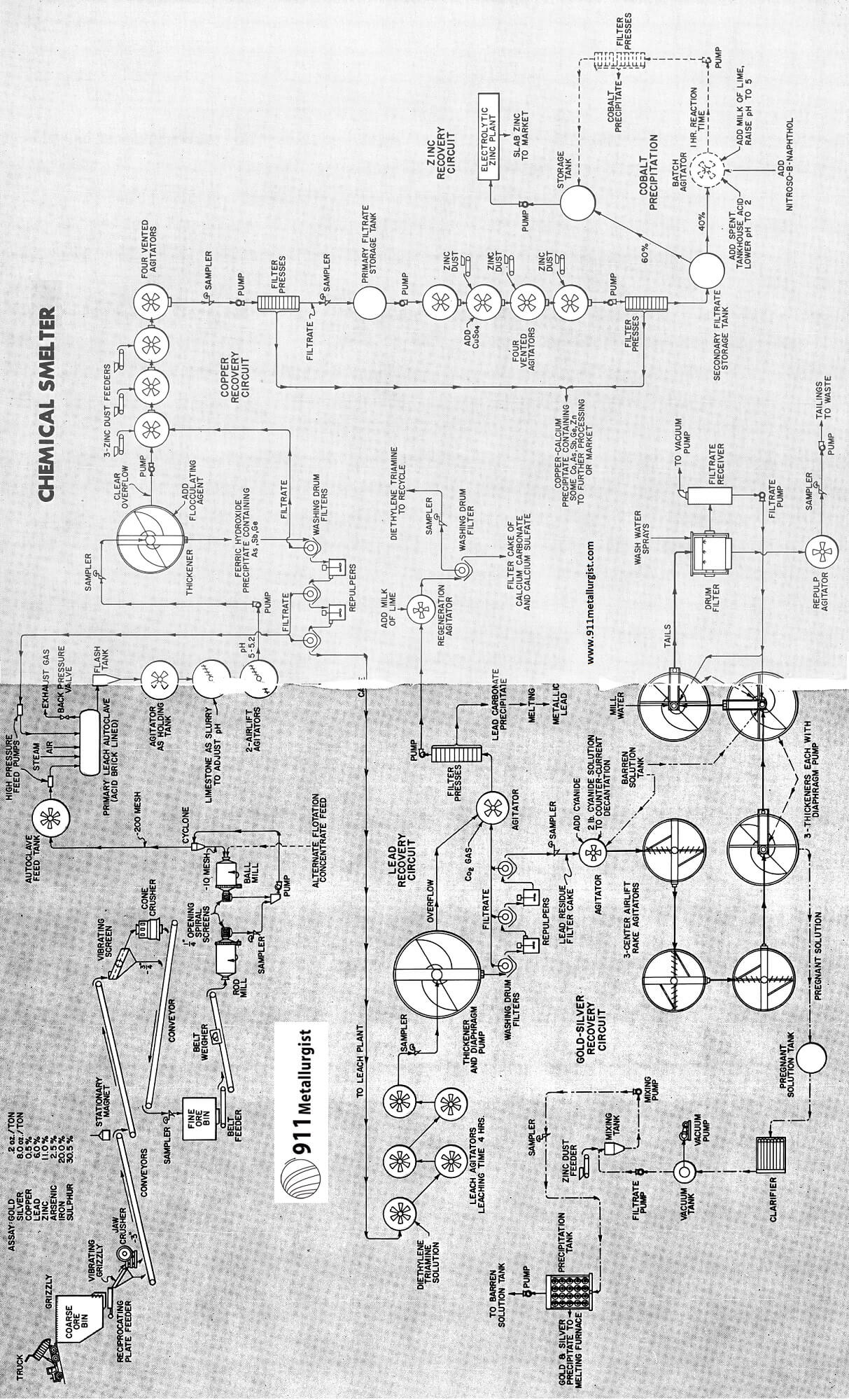

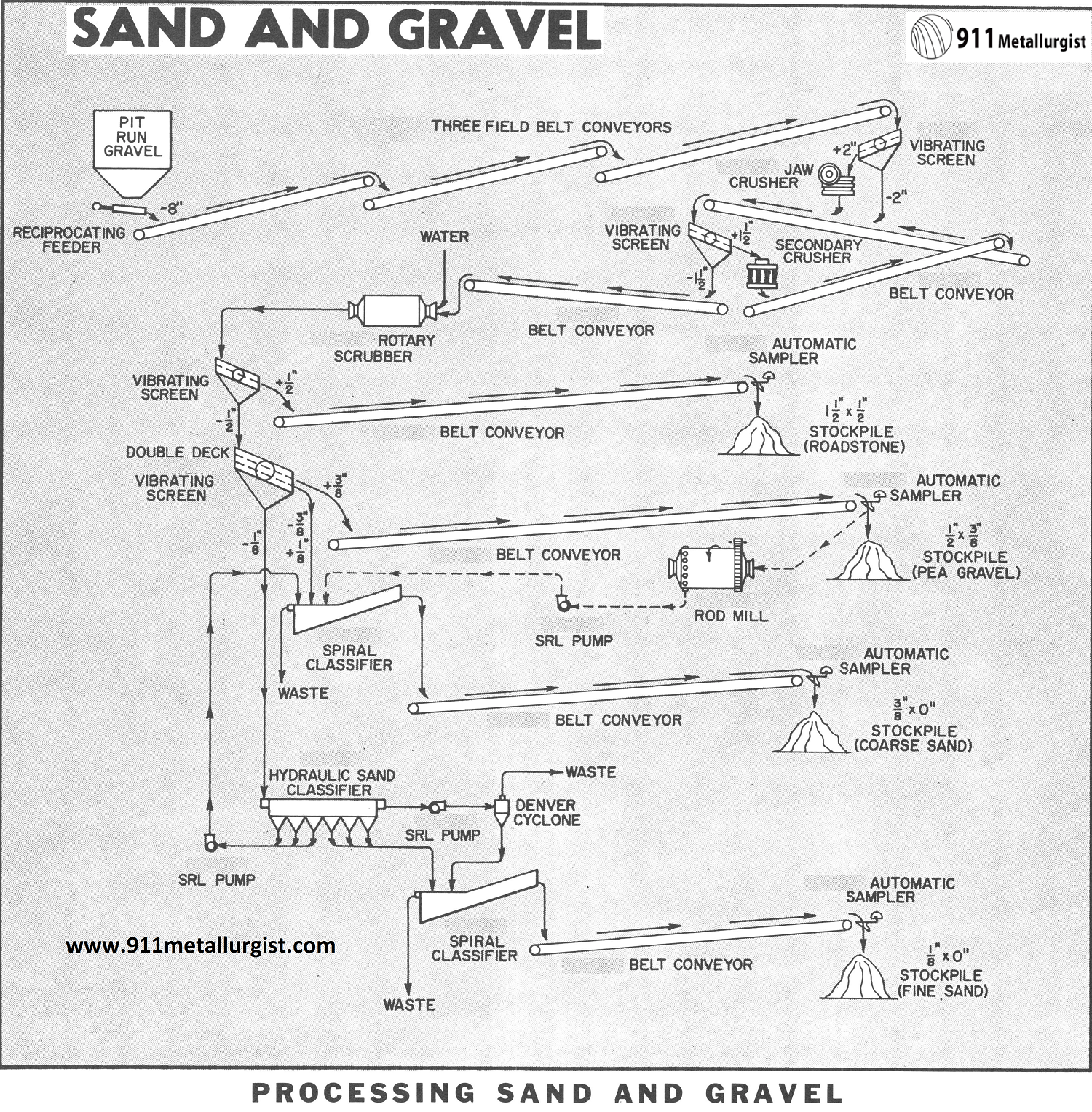

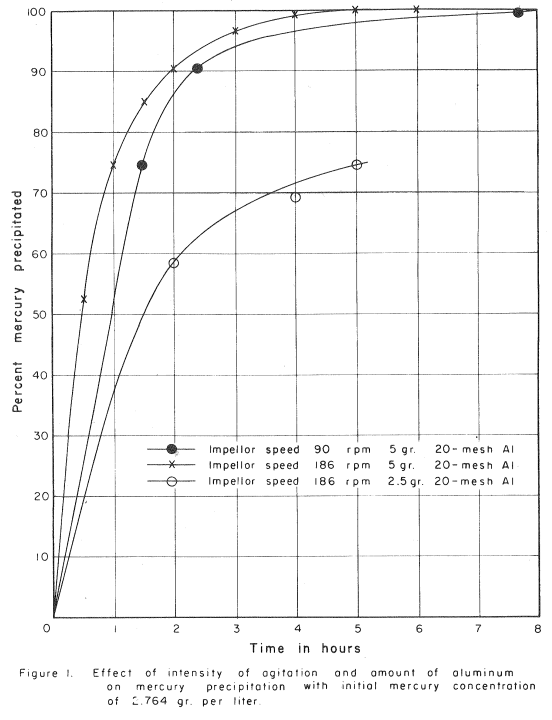

Hydrometallurgical methods have received increased attention for the treatment of many ores in recent years. Whereas, direct furnacing has been regarded as the standard process

Leaching plants, faced with increased tonnage, coarse (up to —3/16″ solids) feed, longer retention time, erosion, corrosion and the high cost of space, must be compact, simple and

Kaolin is an important industrial mineral having numerous uses and requiring various market specifications. High brightness kaolin clays represent a continuing challenge to the producer.