Preparing Flotation Reagents

The following flotation reagent mixing system is typical for the flotation reagent mixing systems: A-208, Xanthate and Sodium Silicate. The reagent mix tanks, for the above

The following flotation reagent mixing system is typical for the flotation reagent mixing systems: A-208, Xanthate and Sodium Silicate. The reagent mix tanks, for the above

A Flocculant like the Dry polymer (Percol 156) is used throughout the process to flocculate fine particles and increase the solids settling, filtration and clarification rates.

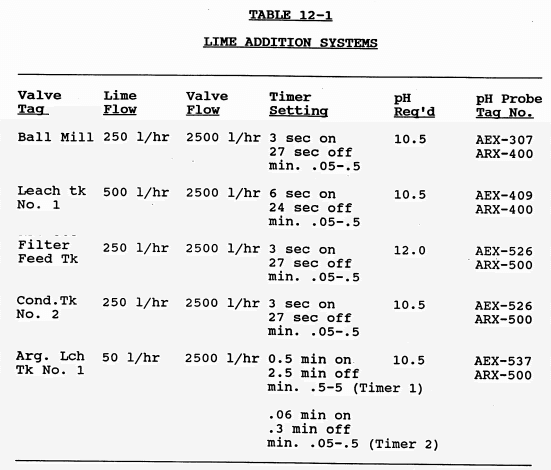

The lime system is a packaged unit which operates automatically and continuously. The equipment provided in the package includes the lime silo, rotary feeder, lime slaker

VARIABLE RANGE EFFECT ON PROCESS Crushing Jaw Crusher Close side setting 3″ plus H – Material too large for cone crusher. N – 3″ L –

In our EXAMPLE precipitate from the – Zinc Precipitation Circuit will be considerably wet and therefore it must be dried prior to entering the induction furnace. Excess

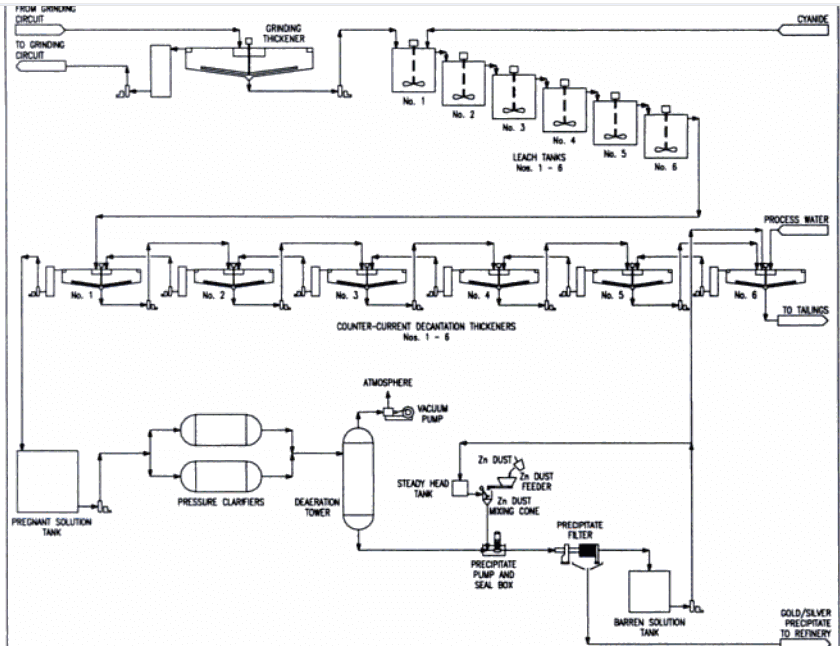

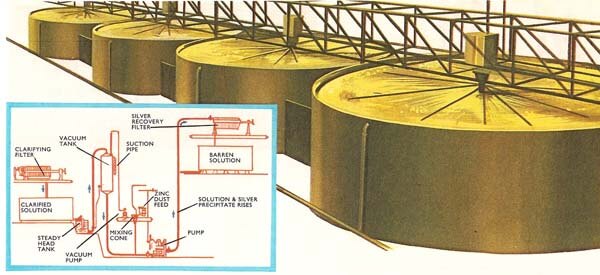

The Operation of a Merrill-Crowe Zinc Precipitation circuit requires for Preparation for its Startup that the following items be checked before the equipment in the Merrill-Crowe Zinc Precipitation Circuit is

In the Merrill-Crowe Zinc Precipitation, the pregnant solution tank collects the gold and silver bearing solution recovered from other circuits of the plant: thickener overflow;

Details of good silver sulphide leaching and filtration circuit operation and instructions for sequencing and preparing for startup. The following items must be checked before

Producing a Silver Flotation concentrate from this EXAMPLE Argentite (cubic silver sulfide (Ag2S)) Flotation Circuit enters the first of four successive Argentite leach tanks. The

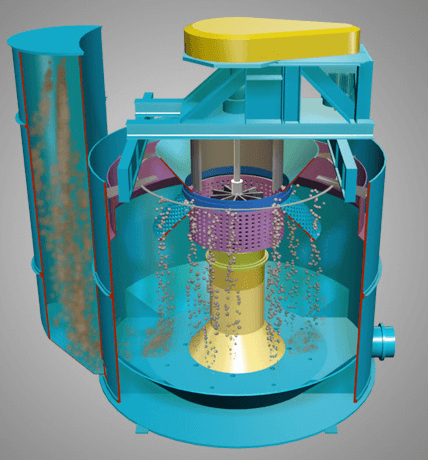

In preparation for this EXAMPLE Startup, the following items must be checked before the associated conditioning and flotation equipment and circuit is started. Ensure that all applicable reagent