Grinding Mill Gear Assembly

We will begin with the mill’s bull gear assembly and work towards the motor, The BULL GEAR, sometimes called the RING GEAR is designed to

We will begin with the mill’s bull gear assembly and work towards the motor, The BULL GEAR, sometimes called the RING GEAR is designed to

Dealing with leaking Mill Shell bolts is common enough an occurrence in most concentrator plants. All that an operator can really do about it is to keep

The Mill Trunnion Liner fits inside the bearing to protect it from wear caused by the ore being washed over the liner and through the bearing

The first part of the mill that we will look at is the TRUNNION BEARING. This is a HYDROSTATIC BEARING which is a slow moving bearing

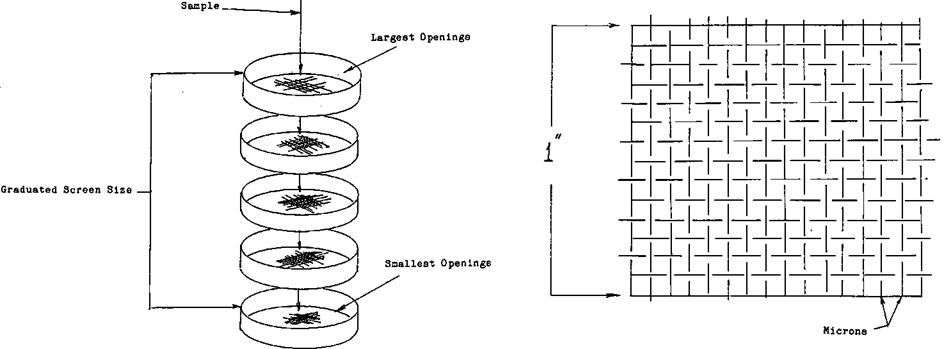

Let me explain as to how a Sieve Analysis is done. If you take a sample of ground ore, heat it until it is completely

The next piece of information that is of value to the operator is to know the hardness of the ore. The WORK INDEX, as the

Mill operators will not get to design too many mills, but this doesn’t mean that the information that has been compiled isn’t of interest to

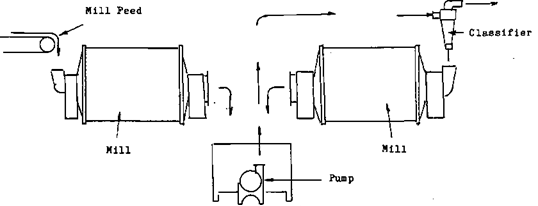

To start the discussion on grinding circuits I would like to begin by showing you some simple Flowsheet SCHEMATICS of some sample circuits, but before

Around these ore storage bins or areas there are three possible places of work, on top, under, and in. Each one has their own brands

Let’s begin with fine ore storage bin or stockpile, get it out of the way and then proceed to grinding. You would think that there