Froth Flotation System

Successful industrial practice has shown that froth flotation sytem needs to be viewed both at the plant level and at the research level as a

Successful industrial practice has shown that froth flotation sytem needs to be viewed both at the plant level and at the research level as a

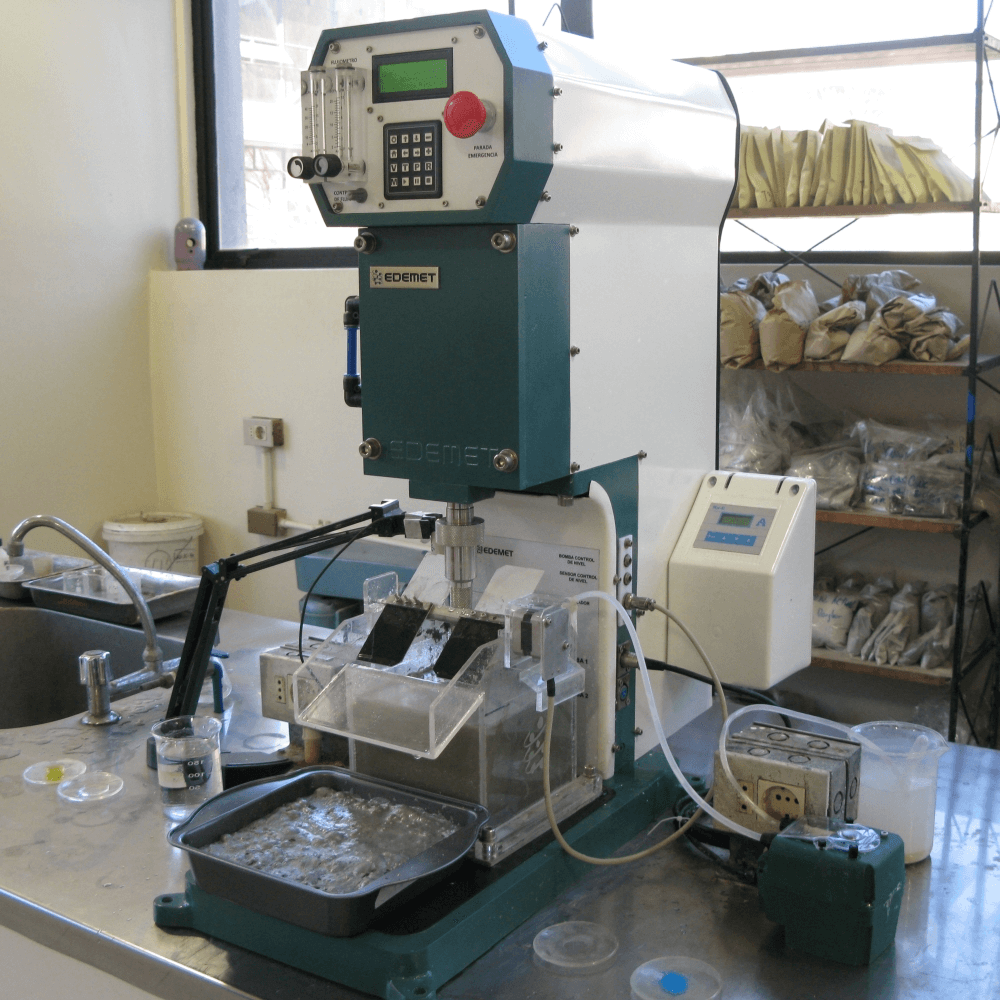

Industrial flotation machines can be divided into four classes: mechanical pneumatic froth separation column air-lift matless As pneumatic and froth separation devices are not commonly

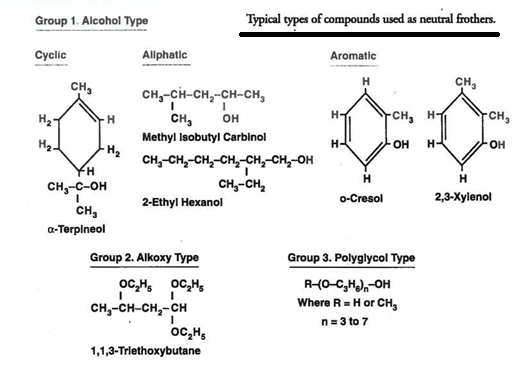

The next reagent that is added is the Flotation FROTHER. The frother strengthens the surface tension of the air that is injected into the flotation

The separation of one component from another by flotation depends on the relative water-wetting ability of the surfaces of the various particle components. Many

Although froth flotation was originally developed for mineral separations in the early 20th century, the use of this process has been extended in the last

Froth Flotation is a mineral processing process achieving solid-solid separation by taking profit of the chemical attribute leading to the possibility of selectively controlling the

So how do we explore for Porphyry Copper Deposits which are completely covered by barren younger rocks? Well let’s back up a bit, we know

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside

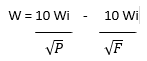

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk

Maximum power is drawn by a mill when the charge occupies approximately 50% by volume. The power curve becomes very flat in the range above