How to Control a Grinding and Classification Circuit

The system chosen has a “fill in the blanks” process control compiler that permits the control loops to be constructed at the system teletype in

The system chosen has a “fill in the blanks” process control compiler that permits the control loops to be constructed at the system teletype in

In the past, it has more or less been a general rule that any time the total product is being washed, both mechanical and thermal

Before the work was started, a review was made of possible oxidative and disposal processes, including: evaporation, ponding, lime-sulfur treatment, acidification-aeration, ion exchange, biological oxidation,

The unit consists of two rotary carriers between which there is a mounted series of independently rotatable slurry receiving baskets which are circumferentially spaced and,

Nickel ores may be classified into two major categories : sulphide ores, and oxidized lateritic ores, these latter containing nearly 80% of the known reserves

You have all seen a gas stove. Gas burns with tiny, bright-blue cones of flame; they are very hot, very clean, very quick to burn.

The processing of residues derived from various operations in the mining and metallurgical industry for by-product recovery is becoming more prevalent. A principal target for

A new suspension electrolysis method has been developed, which enables without any gas or dust pollutants a direct anodic extraction of zinc from zinc sulfide

As part of a larger study to identify factors influencing the practical operating life of wire rope used on large draglines in surface coal mining,

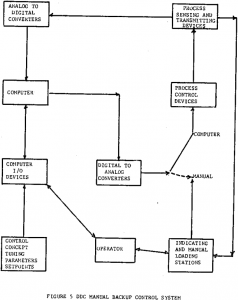

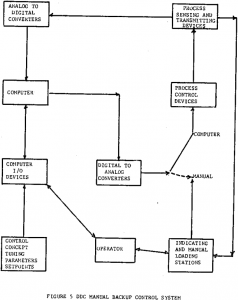

Ideally, mill circuits should be controlled so that excessive random disturbances are reduced in frequency and amplitude. It is difficult to derive an objective measure