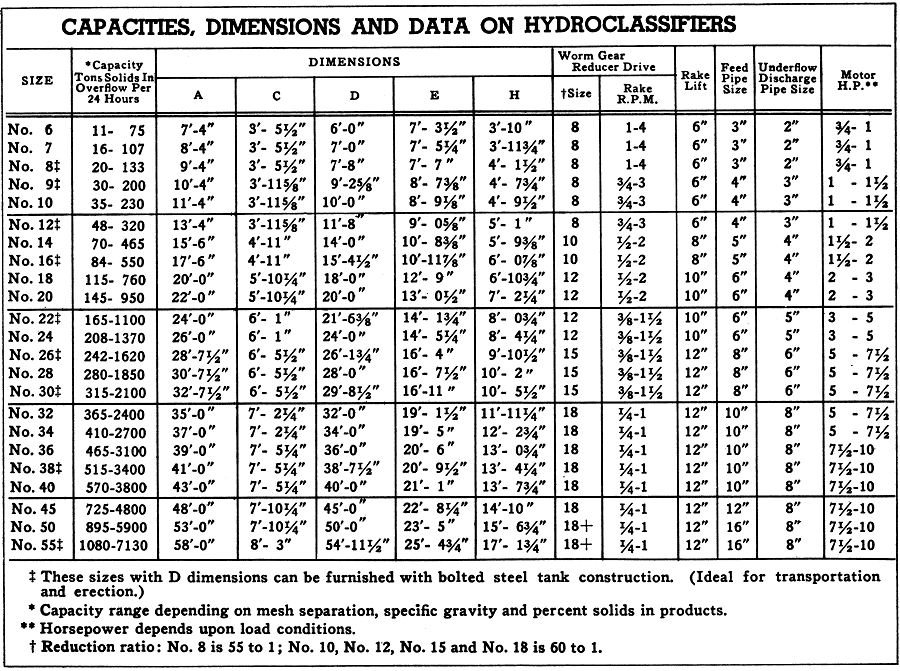

Hydroclassifier

Hydroclassifiers are solving the most difficult fine sizing and desliming problems by combining high metallurgical efficiency in a rugged, well- built machine to accurately fulfill the exacting conditions required. Accurate separations can now be made in the 100 mesh range and finer. This fine separation requires considerable classification area per ton as well as minimum […]