Mineral Processing Pilot Plant Equipment

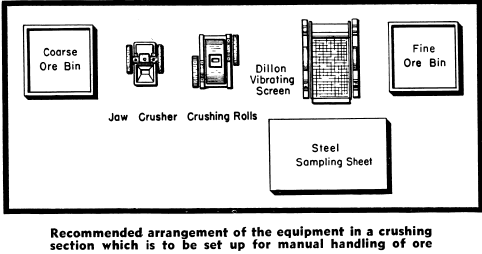

The testing of tonnage lots of ores and industrial materials by continuous Mineral Processing Pilot Plant operation is in many instances advisable before a full scale milling plant is installed. The treatment of complex ores by new processes or by the use of new or unusual reagents in flotation may involve problems the effect of […]

Metallurgical Laboratory Equipment & Test Methods

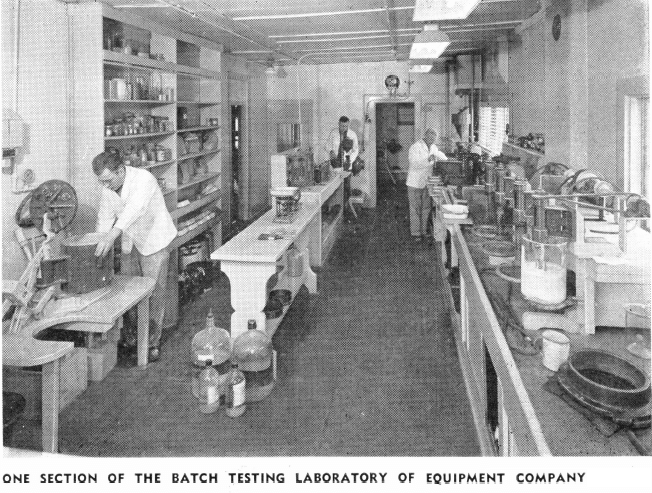

The Mineral Industries have for many years recognized the importance of small-scale ore dressing tests for determining the amenability of ores to various methods of concentration. The successful development of the flotation process, which was accomplished with the aid of small-scale laboratory machines, gave a decided impetus to the laboratory testing of ores. Today the […]

Laboratory Flotation Testing

Batch Laboratory Flotation Testing starts from the 3 fundamental types of flotation processes or methods which can be classed as either: Bulk flotation Differential flotation Sequential flotation While all flotation processes are selective or differential in that one mineral or group of minerals is floated away from accompanying gangue, bulk flotation generally refers to separation […]

Mineral Processing Laboratories

Finding a good and the right mineral processing laboratory and have your testing filled properly is important. Most metallurgical laboratories now are actually specialized. They will claim to “do-it-all” while what they can actually do truly depends on who their current staff is. You have hear the cliché on people are our greatest asset? Well, it […]