Flotation Controlling Factors

The object of this paper is to offer some suggestions to assist metallurgists to supervise the operations of flotation plants. We do not yet thoroughly understand what “flotation” is, or “why minerals float,” and all attempts that have been made to explain the phenomena have been based on theory or imagination, and have not been capable […]

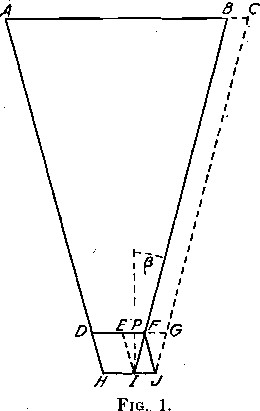

Conical Mill Grinding Tests

In the laboratory work described in the following pages, a 4 ½-ft. Hardinge mill with three removable cylindrical sections, 16 in. each in length, was used. Fig. 1 shows the mill with three cylindrical rings in place. This combination allows a mill 4 ½ ft. by 0 in., 4 ½ ft. by 16 in., 4 ½ ft. […]

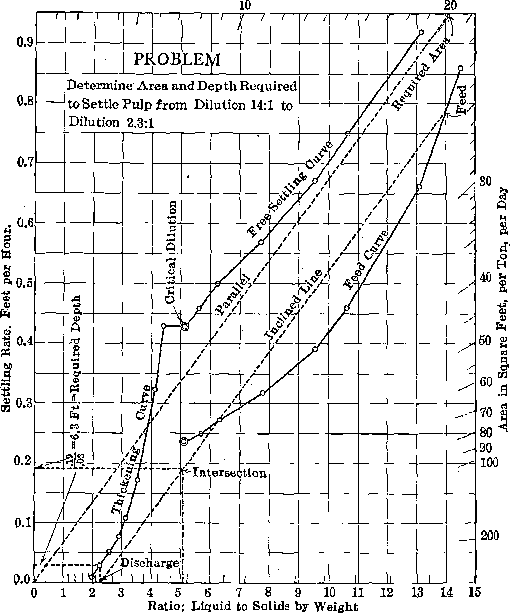

Calculate a Settling Tank’s Capacity – Thickener

During construction work at a mill, the metallurgical engineer in charge, ran a series of experiments on settling. His tests proved that deep settling tanks were not ordinarily necessary. The use of tanks 2 or 3 ft. in depth was suggested. Later experiments demonstrated that the following principles of settling applied to Tigre pulp. In settling dilute pulp, […]

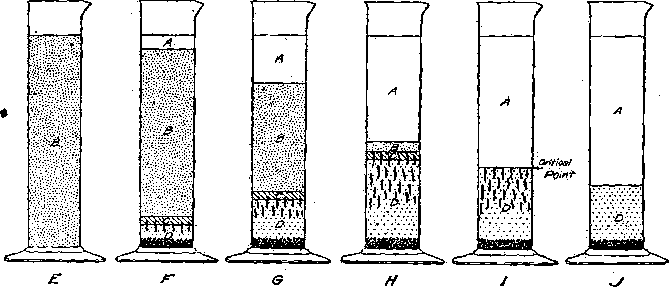

Measuring Settling Rates and Calculating Thickener Capacity

In order to develop rational methods of measurement and laboratory testing, it becomes necessary to study the general phenomena of settling rates. Since it was desired to give the public the benefit of these methods at as early a date as possible, together with the knowledge of the general principles of slime settling necessary for a […]

Factors Controlling the Capacity of Rock Crushers

When estimating the capacity of crushers under given conditions, it is necessary to employ an empirical factor which has here been designated by the letter k, representing the percentage ratio between actual crushing rate, and a theoretical capacity based on the dimensions and other data correlated in equation (12). The accuracy of this factor limits […]