Mobile Ore Processing & Beneficiation Plant

One of the most serious problems confronting the mining industry today is how to profitably begin the small scale milling of ores from mines where insufficient ore has been developed to warrant an expensive mill installation, but where a large plant might be needed later. The same question arises in connection with the economical working […]

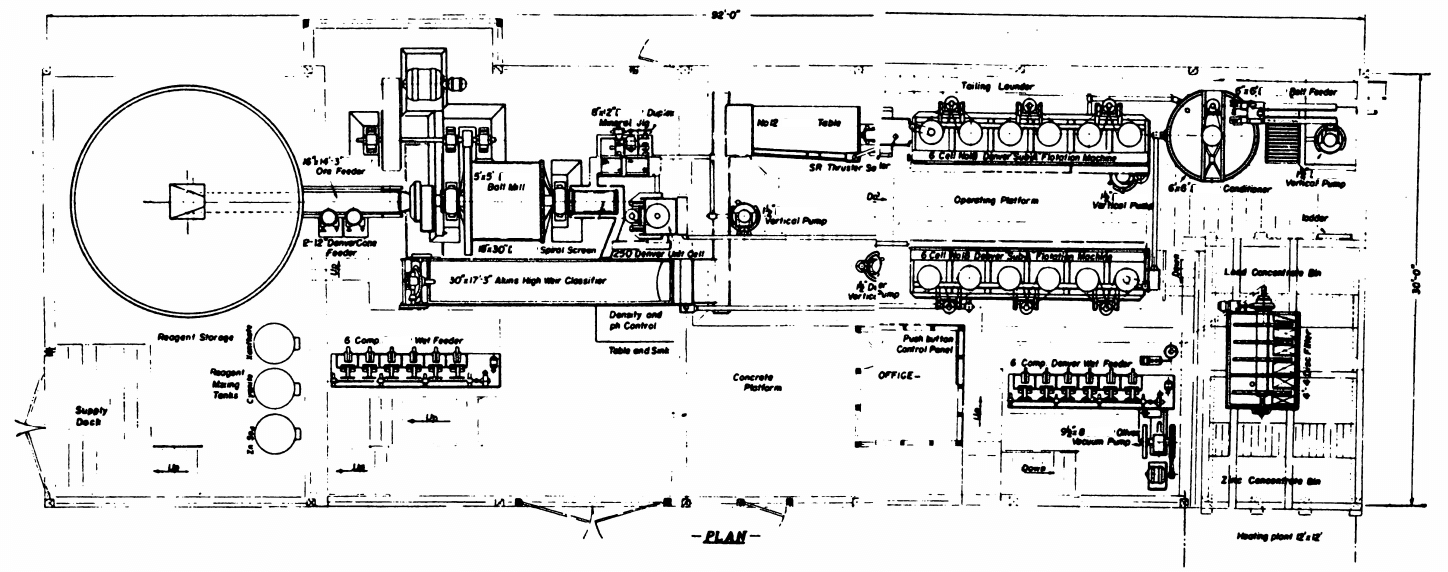

100 to 125 TPD Process Plant Design & Equipment

The 100 to 125 Ton/Day Mill is arranged along the same standard lines as the smaller mills, and a large oversize forced feed crusher is recommended for primary crushing. An intermediate crusher can be installed later if necessary. Changes can be easily made according to your local conditions. Here too, a Selective Mineral Jig may be […]

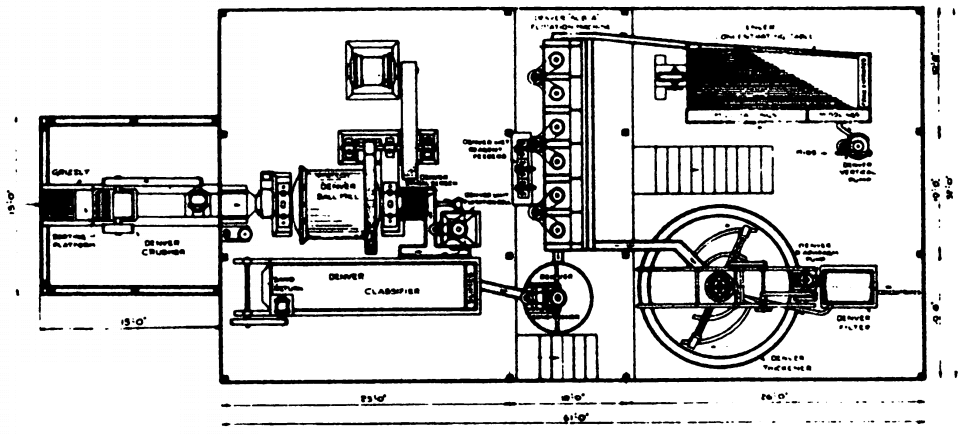

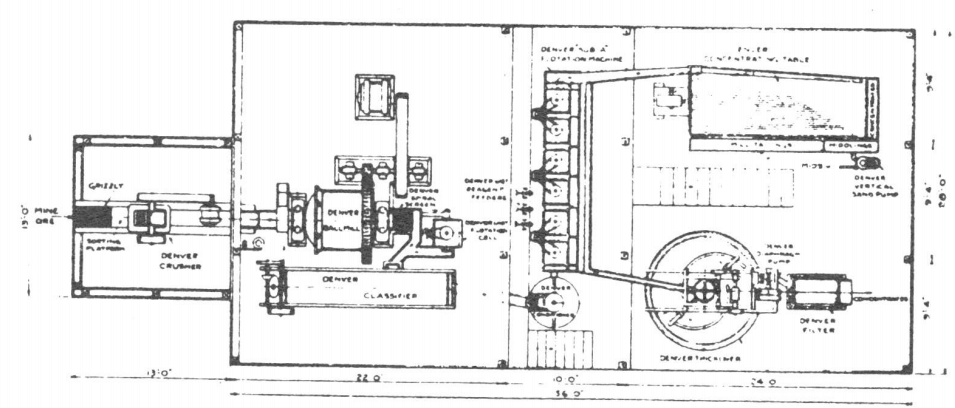

Small 50 to 75 TPD Process Plant Design & Equipment List

The 50 to 75 Ton per Day process plant is the most practical size for the average milling plant. The 9″ x 16″ Jaw Crusher (forced feed) produces enough crushed ore for the ball mill on one eight hour shift to run the balance of the mill for twenty-four hours. Oversize primary crushers are recommended for […]

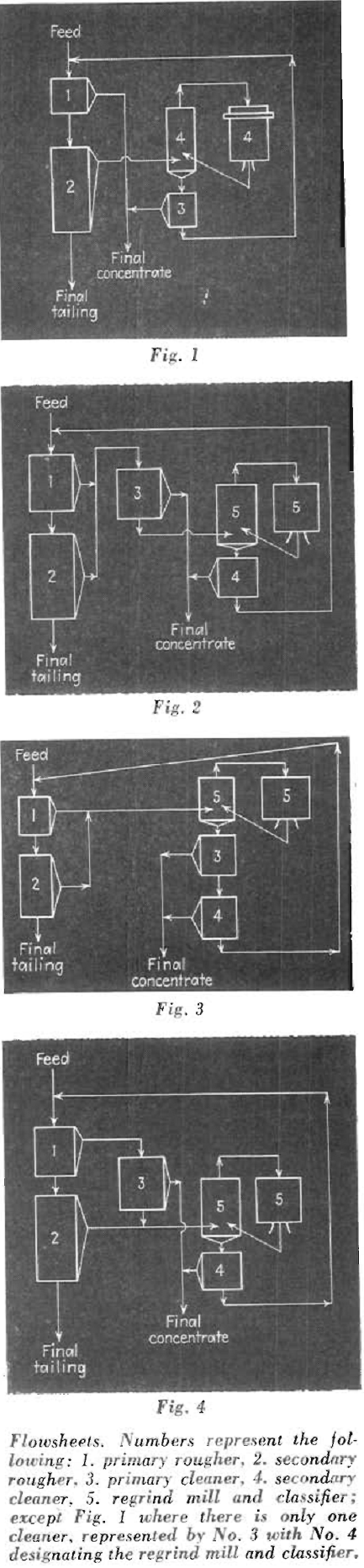

Mineral Processing Flowsheets

The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants. Metallurgical data are shown in these flowsheets which incorporate Crushers, Grinding Mills, Flotation Machines, Unit Flotation Cells, and Selective Mineral Jigs as well as other standard milling equipment. The Flotation Machine, the Selective Mineral Jig and […]