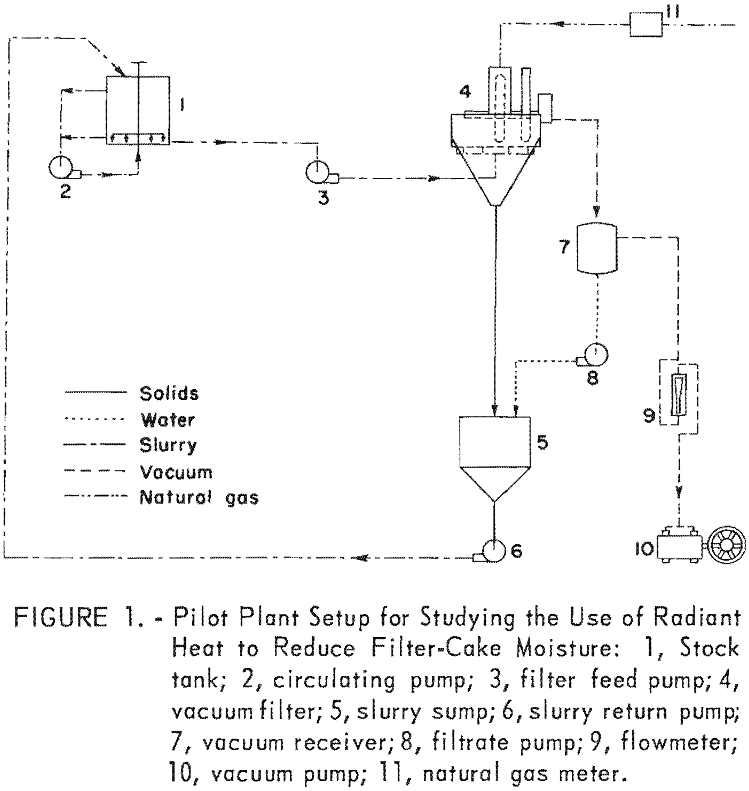

Dry Filter Cake using Radiant Heat – Reduce Moisture

This report stems from a study by the Bureau of Mines of the possibility of reducing coal filter-cake moisture by applying radiant heat directly to the filter cake while under vacuum during the drying phase of the filter cycle. One disk of a 4-foot-diameter vacuum filter was equipped with gas-fired radiant-heat generators and the effect […]

How to Improve & Aid Slurry Filtration by Flocculation

The experimental results appear to support two principal conclusions: First, the three natural and three synthetic slurries tested all exhibited individual filtration characteristics and individual flocculation properties; moreover, their behavior was not related directly to either size composition or ash content. Thus each slurry must be evaluated individually in predicting the possible benefits of fIocculation. […]

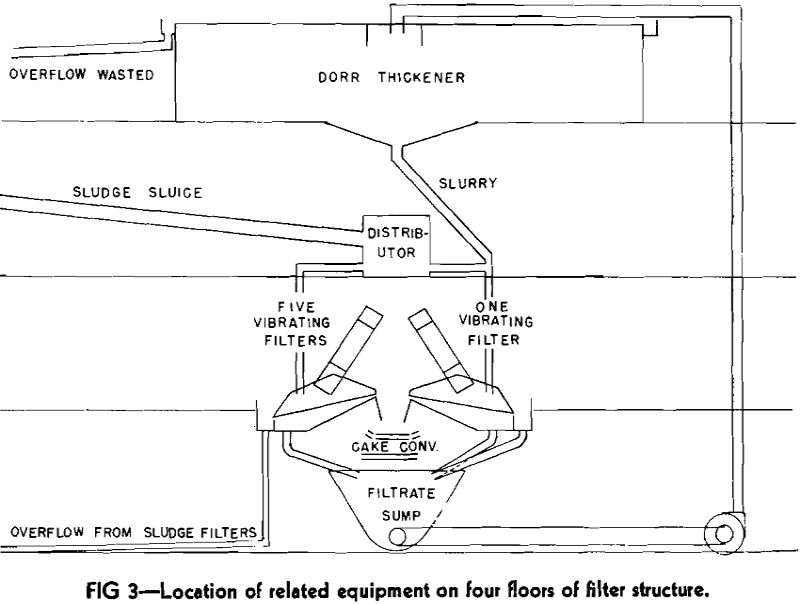

The Rupp-Frantz Vibrating Filter

One of the chief difficulties with which the operator of a coal washing plant has been forced to contend is the handling of the very fine coal. First he has the problem of separating the fine coal from washery water. This is usually accomplished by the use of settling cones or Dorr thickeners: in either […]

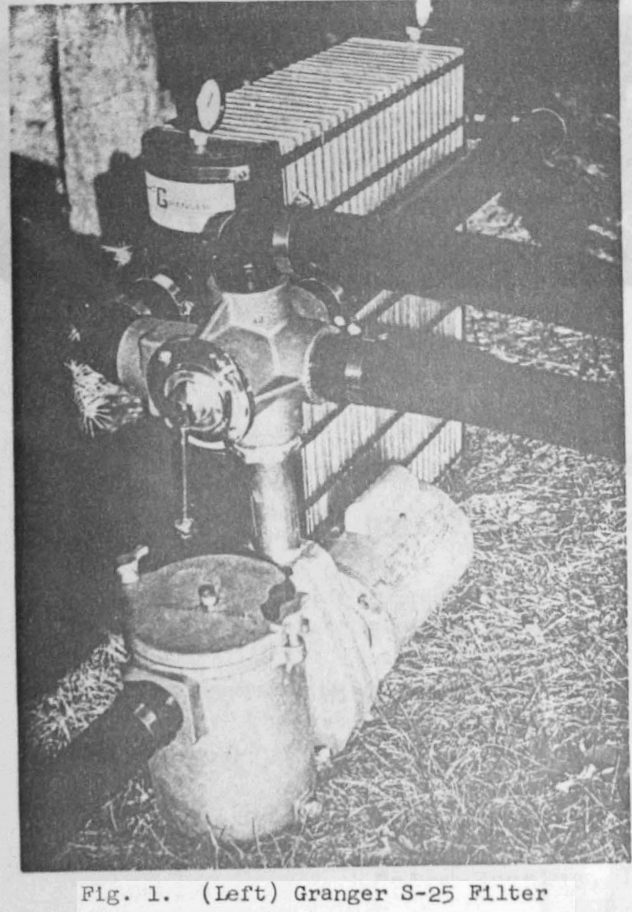

Clarified Solutions by Reversible Cake Filtration

In order to filter small amounts of fine slimy solids the reversible cake filtration process was developed. The filterable solids concentration in feeds can range from less than 1 ppm up to about 5%. The relative advantages of this process are usually the greatest in the range of.0.05% to 1.0% filterable solids. Filterable solids that […]

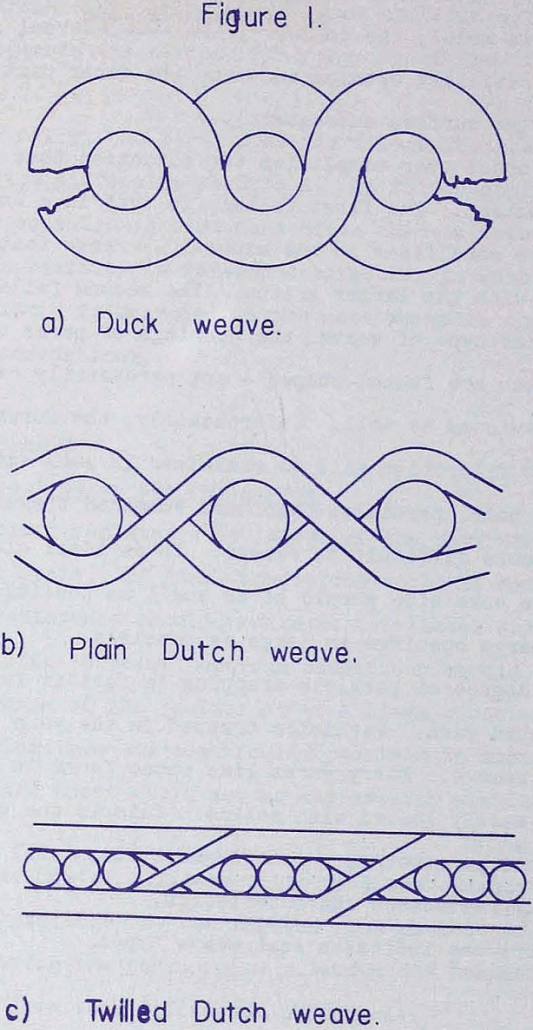

Filter Medium in Continuous Vacuum Filtration

The filter is an apparatus designed to hold the filter medium. At such a medium takes place the entire liquid-solid or gas-solid separation process. Hence, the medium is really the essence of filtration. Yet, the medium, an originally clean porous substance with trapped solids in it, is perhaps the most neglected part of filtration research. […]

Continuous Countercurrent Decantation and Filtration

In extractive metallurgy, separation of insoluble solids from solutions is an important economic factor in almost all flowsheets. This separation step can employ sedimentation, filtration (vacuum and pressure), or centrifugation. Since practically all systems require a relatively complete separation, multiple unit, countercurrent thickeners or vacuum filters are generally used. Continuous Countercurrent Decantation In its simplest […]

Centrifuge System

The unit consists of two rotary carriers between which there is a mounted series of independently rotatable slurry receiving baskets which are circumferentially spaced and, therefore, during rotation of the carrier, orbit about the axis of rotation of the carrier. The speed of the rotating carrier plates determines the centrifugal force available, while the speed […]

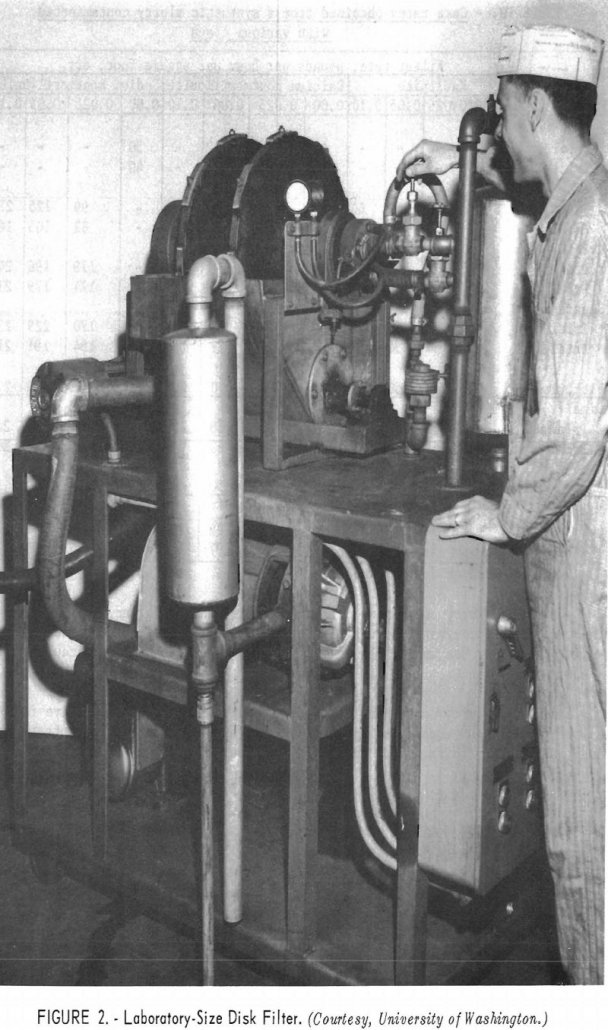

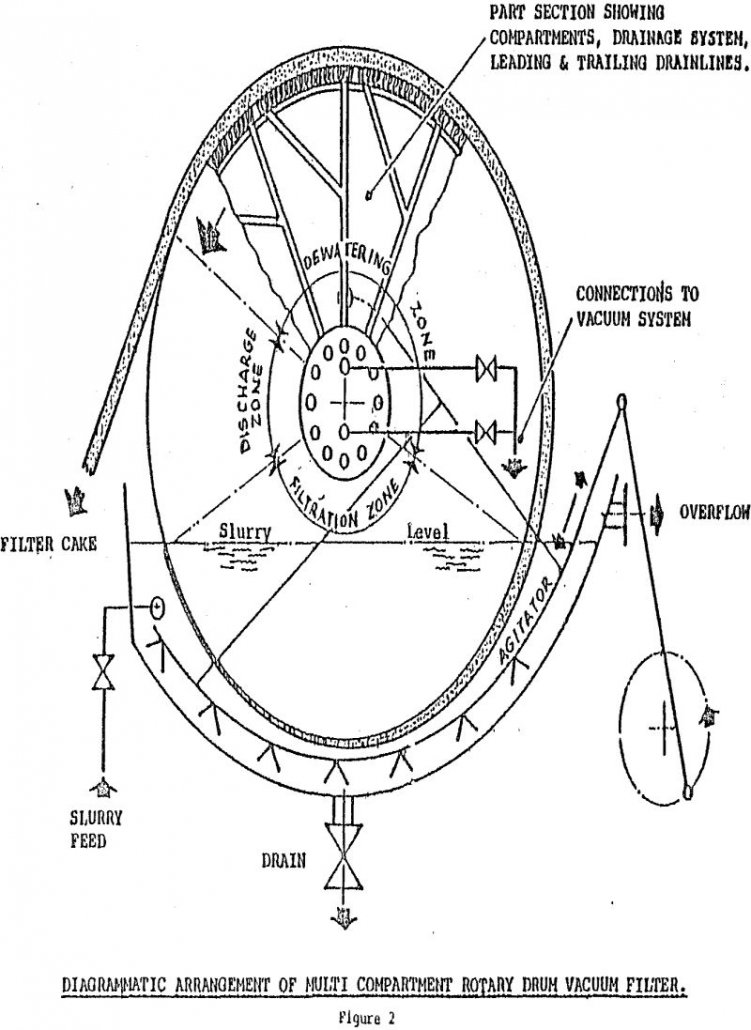

Vacuum Filtration

In reviewing available vacuum filtration equipment in this paper, several types of filters have been included which are probably not familiar to operators in the mining industry. However, it was felt that these units might be of interest in the event that an application should arise for the filtration of a product in the future […]

Vacuum Filters for Dewatering

The pelletizing process for low grade iron ores has undergone continual changes since its inception over twenty years ago. These changes have necessitated filtration equipment changes in order to produce a product suitable for balling. With modern techniques it is now possible to produce pellets of 68% Fe from ores containing as low as 26% […]

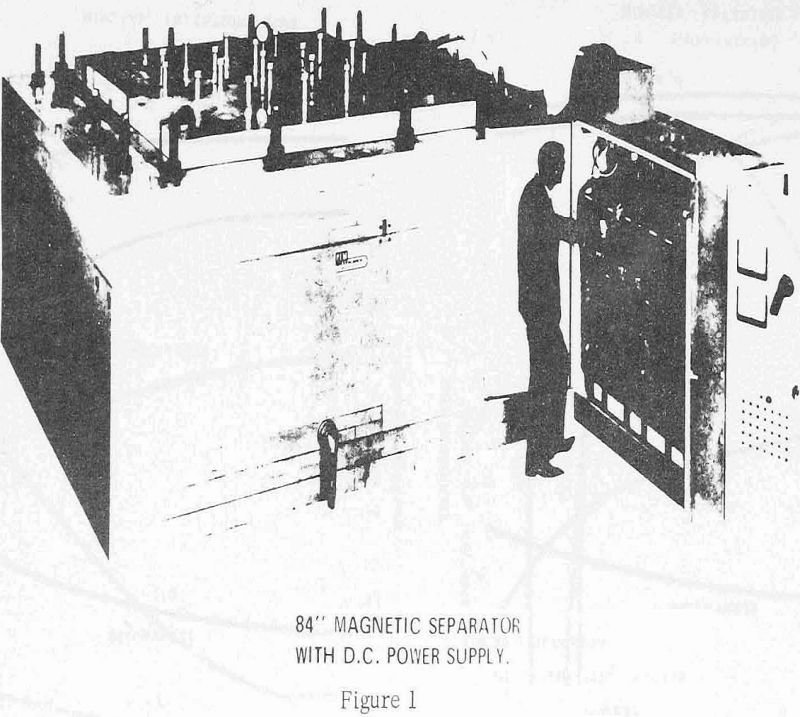

Magnetic Filtration of Kaolin Clay

The kaolin development brings together for the first time four concepts that make practical large scale use of high extraction magnetic filtration (HEMF). These include retention time, extreme gradients, high intensity fields, and efficient design of large high field magnets. Each of these elements was known and available but never refined and optimized in magnetic […]