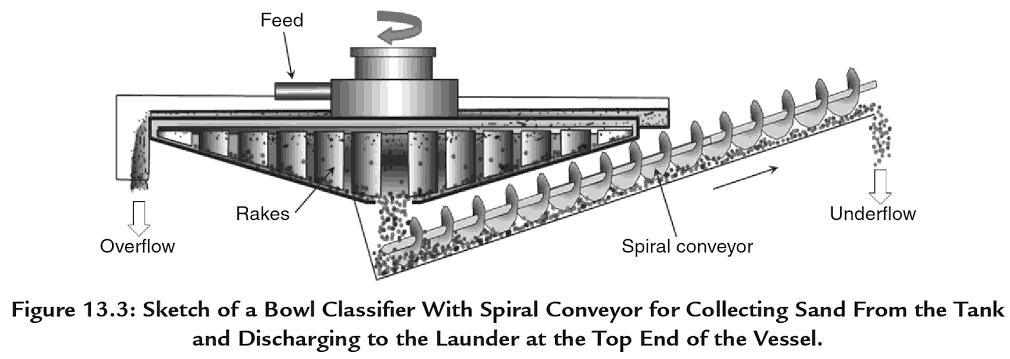

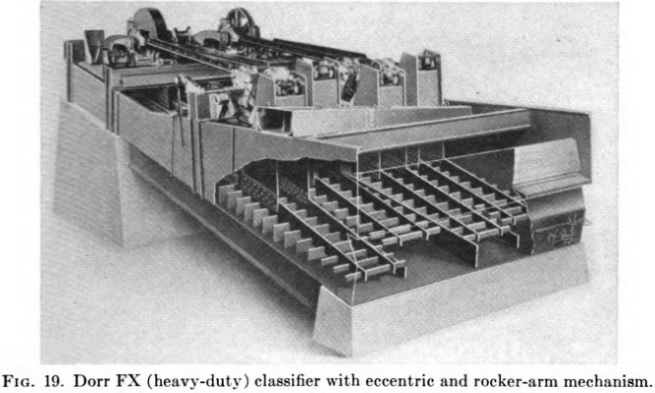

Bowl Classifiers

The bowl classifier incorporates a two-stage baffled-return separating action, and it consists of a straight classifier with the usual reciprocating rakes, upon which is superimposed at the lower end a shallow circular bowl with a revolving rake mechanism. The general construction of the Dorr Bowl Classifier is shown in Fig. 20. The feed enters at […]

Hydraulic Classifiers

Hydraulic classifiers range from simple V-shaped launders with a multiplicity of shallow settling pockets for the discharge of as many roughly sized products to the more elaborate deep-pocket machines of the hindered- settling type, having specially designed construction plates and automatic discharge of spigot products. Dorrco Sizer In the eight-pocket machine, the pockets are separated […]

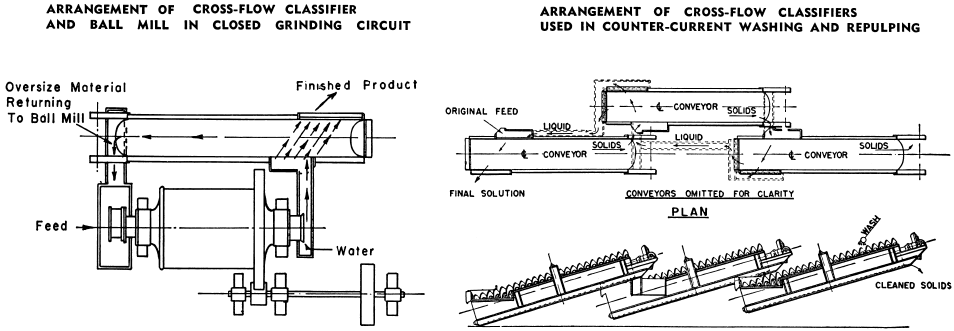

Screw-Spiral Classifier: Select, Size & Install

The size of mechanical classifier required for a particular job depends on the following factors: Tons of dry solids to be overflowed per 24 hours. This is simply a predetermined tonnage. Mesh size at which separation is to be made. The mesh size is determined by laboratory tests or is already known from previous experience. […]

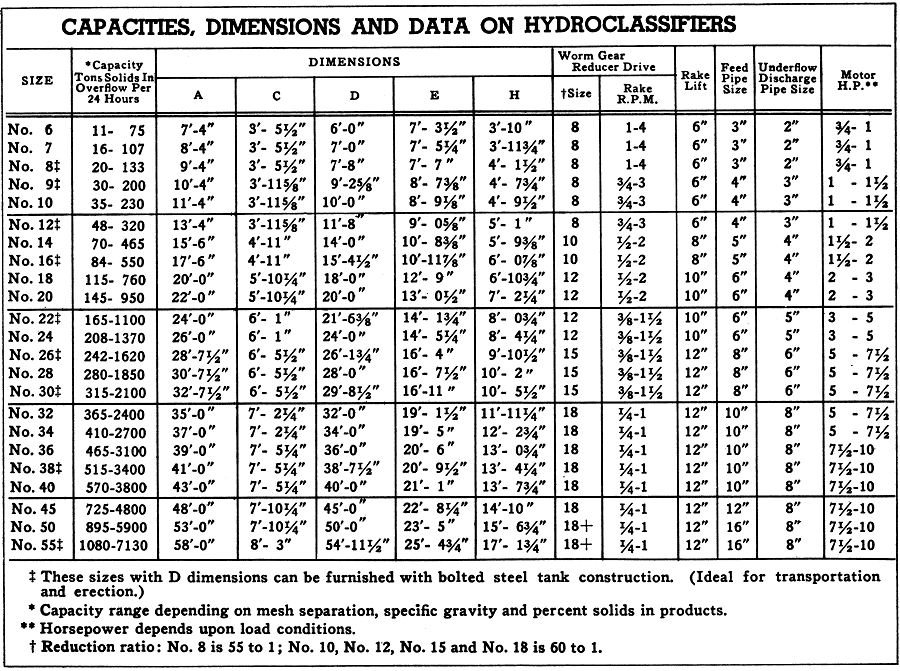

Hydroclassifier

Hydroclassifiers are solving the most difficult fine sizing and desliming problems by combining high metallurgical efficiency in a rugged, well- built machine to accurately fulfill the exacting conditions required. Accurate separations can now be made in the 100 mesh range and finer. This fine separation requires considerable classification area per ton as well as minimum […]

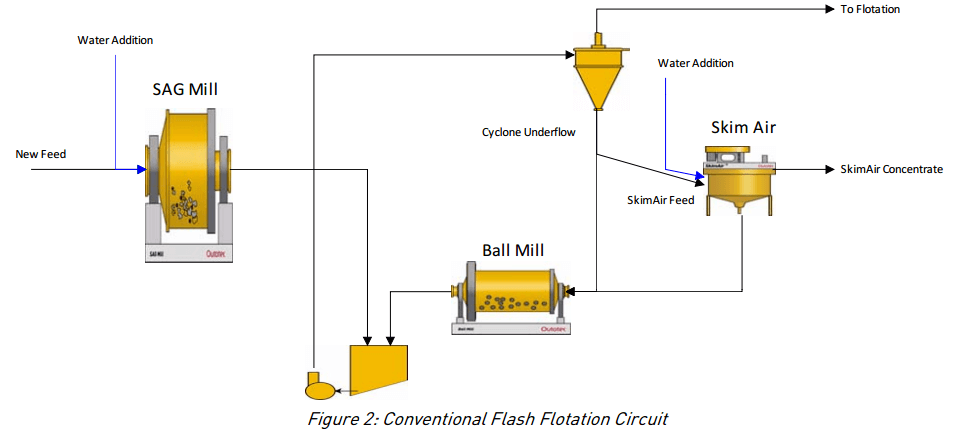

Flash Flotation with Closed Circuit Grinding

The reason why you need Flash Flotation in a Closed Grinding Circuit relates to “Recovering your mineral as soon as free” which has long been recognized in ore dressing practice. This not only applies to gravity treatment but also to flotation. For this application the Flash Flotation Cell was developed for use in the grinding circuit and […]

Grinding and Classification Circuit

Our EXAMPLE Grinding and Classification Circuit is designed to grind 500 tonnes of ore per day, operating 24 hours per day, with an availability of 95%. This circuit will grind -5/8″ material from the Crushing Plant, classify the slurry in one of two cyclones, and pass 70% of the minus 200 mesh material to the […]

How to Improve Cyclone Separation

Good cyclone separation depends upon control of pressure drop, pulp density and apex size. The ‘pressure drop’ may vary but should not change rapidly, and is held at safe levels by keeping an adequate sump level. A falling sump level causes cavitation in the pump and reduction in feed rate; pressure drop in the cyclone […]

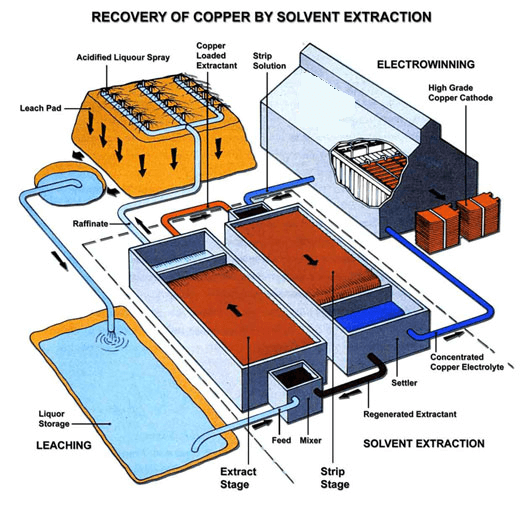

Solvent Extraction & Electrowinning (SX/EW) Plant Design

Cerro Verde began operations in April 1977, originally formed and operated by Minero Peru, as a state-run mining company. The electrowinning tankhouse was designed to produce 33,000 metric tonnes per year (mtpy) of copper cathode operating with current density of 184 amps per square meter (A/m2) and 88 percent (%) electrical current efficiency. In 1994 […]

Hydrocyclone Rubber Liners

We sell Rubber Liners for Hydrocyclone: You can buy parts like the main body liner, lower cone and Apex or Vortex. Long lasting, good wear and better price VS life relationship than a Linatex types Brand.

Hydrocyclone Wholesale

If you are looking for a affordable quality Hydrocyclone Wholesale, contact us.