RADIUM, URANIUM & VANADIUM Extraction & Recovery #1

Until recently little had been published on methods of treating any of the uranium ores for the extraction of radium, although a number of patents have been issued both in this country and abroad. Therefore persons interested in methods of extracting radium have had little to guide them, as details of the methods in use have […]

Copper Precipitation Methods

In a leaching process, having obtained the copper in solution, the choice of the precipitation method is influenced by the following factors: Availability of precipitant. Adaptability to the leaching process. Final product desired. Regeneration of leaching solutions. Fouling of solutions. There are three general classes of copper precipitation methods: 1. The copper precipitation by use […]

Method of Precipitating Copper

During the last few years we have been doing considerable experimenting on methods of precipitating copper. The first patent on precipitating from sulphate solutions by heating with SO2 under pressure was taken out by us (U. S. Pat. 723,949). This reaction, CuSO4 + SO2 + 2H2O = Cu + 2H2SO4, is interesting, but there are […]

Leaching Copper: Iron form Electrolyte

The solvent we would use; how we would precipitate the copper from the solution, and what we would do with the iron in the electrolyte. Without going into the details of the reasons, we decided that sulphuric acid would be the most satisfactory solvent and that we would recover the copper from the solutions by […]

How to Recover Copper from Solution

At the beginning of our investigation we seriously considered what I called the “brutal method” of leaching, namely, the manufacture of sulphuric acid, the solution of the copper from the ore with such acid, and the precipitation of the copper by metallic iron, with the resultant complete, or nearly complete, destruction of both acid and […]

Copper Leaching Problems & Solutions & Procedures

In recent years the metallurgical field of the copper industry has expanded greatly, the copper ores have become lean and diverse in character, and we are obliged to treat such ores on a very large scale. On the commercial side, the operating and consulting staffs of the great mining companies have been enlarged and organized, […]

Copper Leaching Method

The advance made in recent times in this branch of metallurgy is indicated by the attention the subject is receiving from important American Copper producing companies. Reference to the files of publications devoted to the mining industry discloses that some 20 American companies are actively investigating the amenability of their ore, or other material, to […]

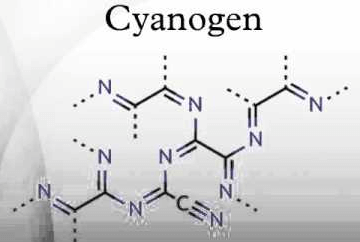

Cyanogen Compounds Chemistry

It is a common observation that the improvements introduced in practice since the first announcement of the cyanide process have been almost entirely mechanical. Although a good deal of study and research has been devoted to the chemical problems involved, the results obtained appear trifling in comparison. Few of the suggested modifications in the chemical […]

Precipitating Gold & Silver Using Metallic Minerals

While the reducing action of organic matter, of ferrous sulphate, and of hydrogen sulphide has frequently been invoked to account for the deposition of native gold and silver from ore-forming solutions, the high efficiency in this respect of certain of the metallic minerals which form the ore itself has not been sufficiently recognized. If a […]

Agitation Leaching in Parral Tank System

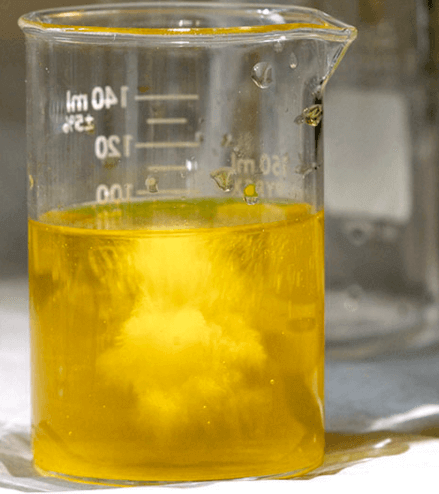

Of the treatment of the slime-pulp of gold- and silver-ores by cyanidation, agitation is an essential part. When prepared for treatment, this pulp, consisting of ore reduced to such fineness that approximately 80 per cent, of it will pass through a 200-mesh screen, is mixed with a certain proportion of water, carrying in solution the […]