Radioisotopes Applications

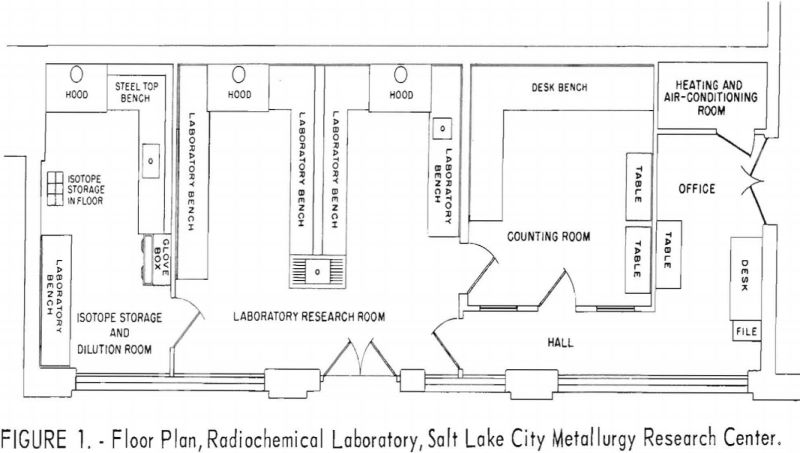

Many factors contributed to the decision to build a radiochemical laboratory at the Salt Lake City Metallurgy Research Center to investigate the application of radioactive isotopes and chemical compounds in extractive metallurgy. These reasons included the notable success achieved in biological sciences with radioisotopes, the development of reliable instruments and methods for identifying the isotopes […]

Limonite Siderite Iron Ore Beneficiation

A laboratory mineral-dressing investigation was conducted by the Federal Bureau of Mines on four limonitic and four sideritic iron ores from the North Basin of the east Texas iron-ore district. The samples, composited from drill cores, were considered representative of the iron-ore reserves of the area. The objectives of this research were twofold: (1) To […]

CUTTING MILL

Our line of cutting mills includes models which reliably process: soft, medium-hard, elastic, tough and, fibrous materials. All models are based on the same grinding geometry and feature. Depending on which model, our cutting mills may feature: Variable speed and adjustable in a range from 700- 3000 revolutions per minute A fixed rotational speed of 1500 […]

How to Prepare Thin Rock Sections

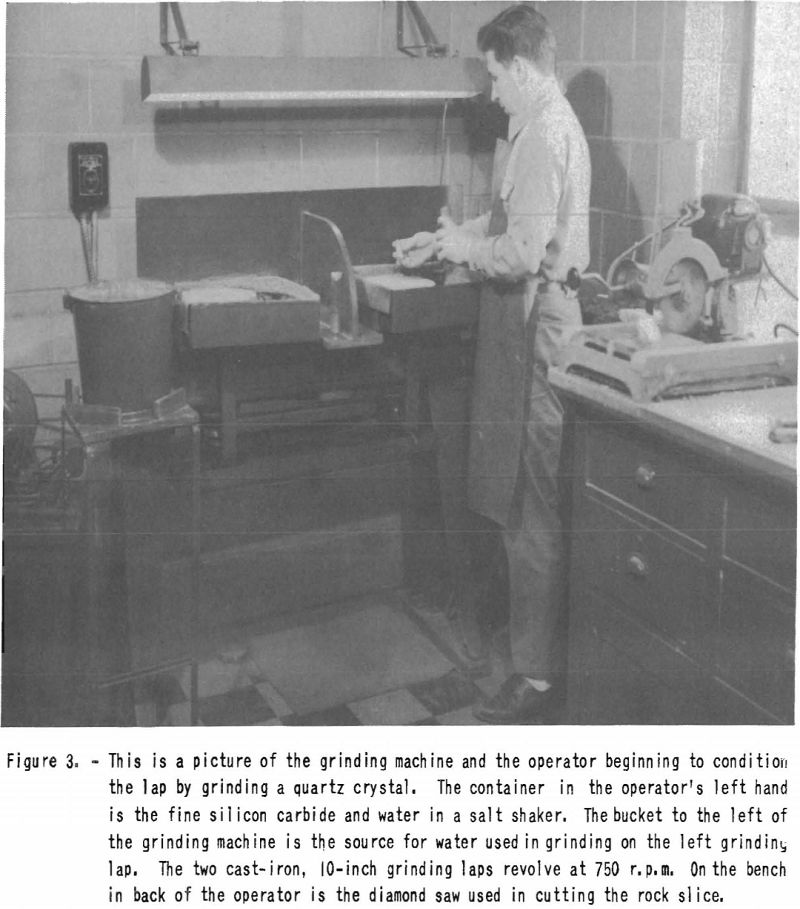

In this recommended method of preparing a thin section the operator begins by obtaining a rock slice approximately 1 inch in diameter and 1/8 inch thick. The rock slice is ground on the coarse and fine grinding laps until a flat surface without visible pits is produced on one side. An important step in the […]

How to Identify the Surface Texture of Rock

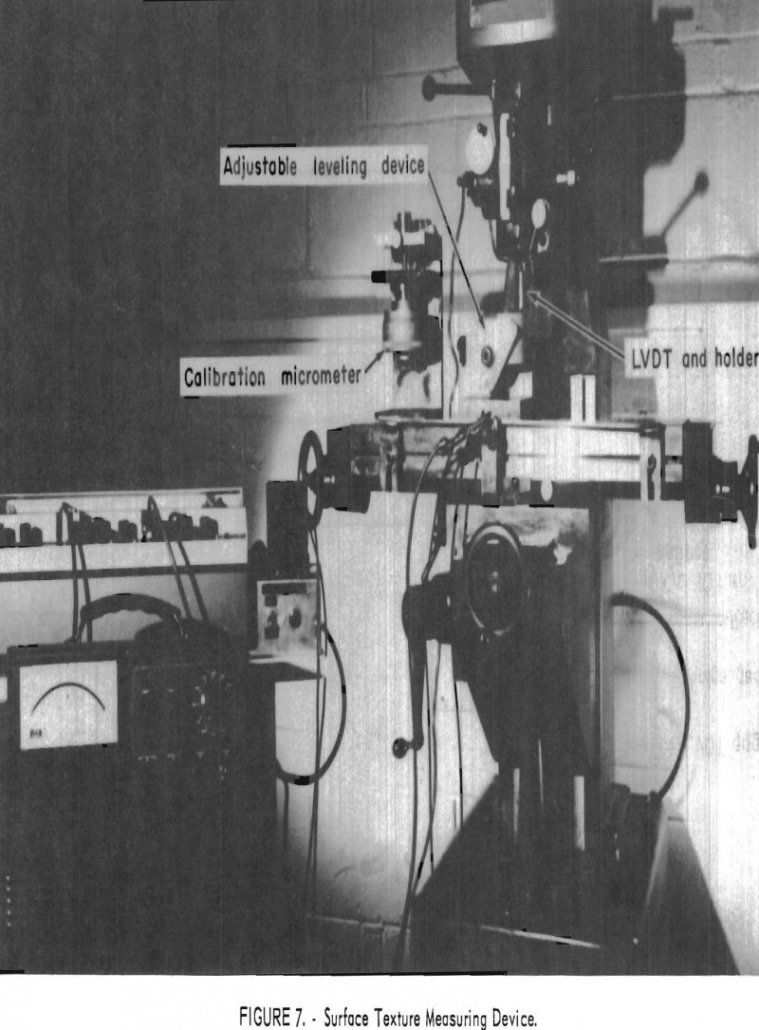

Model studies, using rock, require carefully prepared specimens. Most preparation procedures use some form of grinding or polishing as the last of several steps. During these steps, particularly the final one, the surface formed acquires a configuration defined as texture. Texture is a composite term identifying the physical features called flaws, lay, waviness, and roughness. […]

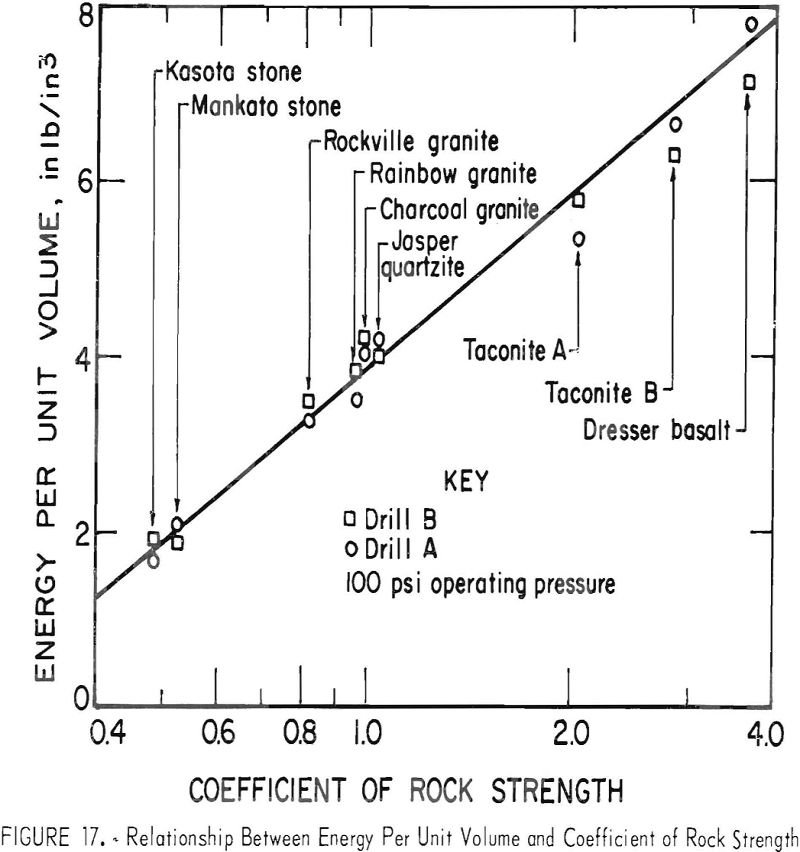

Drillability – Percussion Drilling

Penetration rate is increased by an increase in applied thrust up to an optimum point after which penetration decreases until the drill eventually stalls. Higher operating pressures result in increased penetration rates with the only apparent limitations being the design characteristics of the drill and bit and the ability to remove the cuttings produced. Rock […]

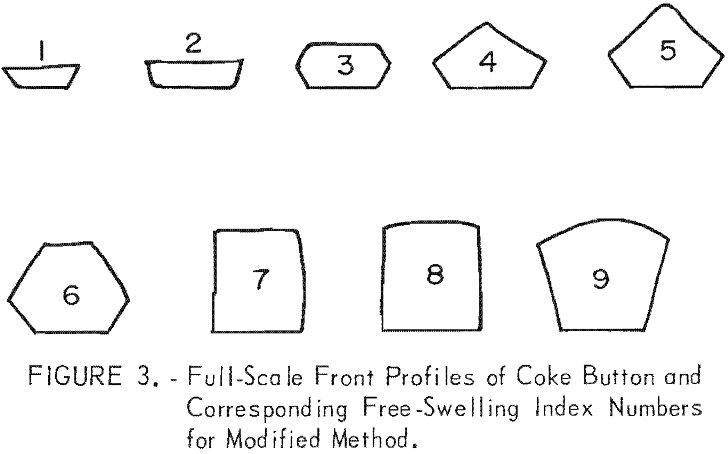

Coal Free-Swelling Index Testing

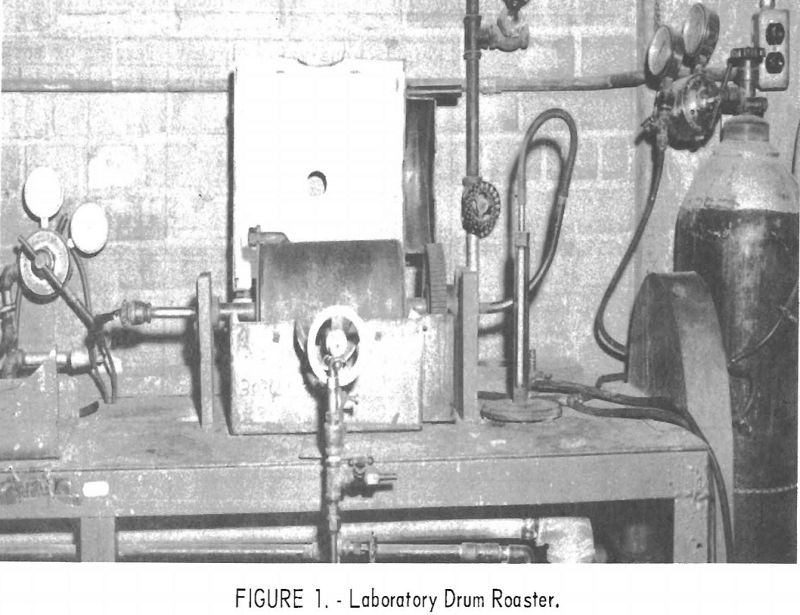

The term “free-swelling” is applied to the behavior of some bituminous coals when heated under specified conditions. Damm defined the swelling of coal as the volume change that takes place when coal is heated. The softened coal can expand, for example due to gases being released on pyrolysis, in the direction away from the heating […]

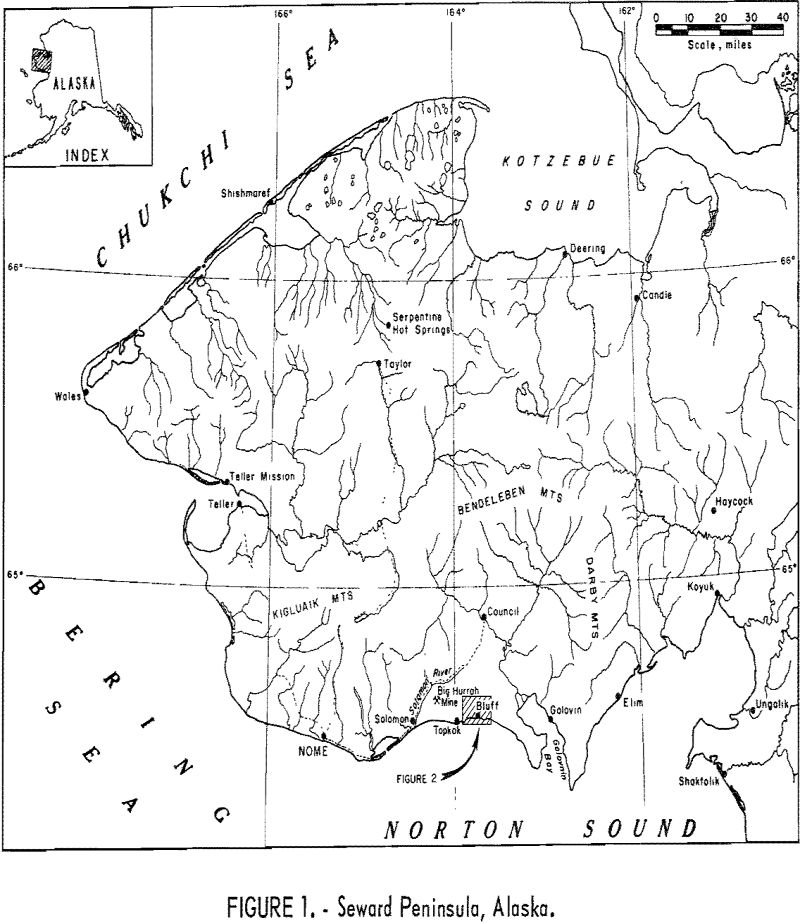

How to Sample Gold Lode Deposits

Placer and lode gold deposits near Bluff, Seward Peninsula, Alaska (fig. 1), were investigated during July and August 1966. The primary objective of this Bureau of Mines investigation was to sample a typical gold lode deposit as a basis for estimating the potential economic value of the lode sources of the productive Seward Peninsula gold […]

Aluminum Alloys – Chemical Spot Tests

The Bureau of Mines is developing technology which will contribute to realizing the most effective use of recycled metals. Development of improved methods for the rapid identification of aluminum alloys has been included in this program. Methods for use outside the laboratory by nontechnical personnel for the identification of wrought alloys have been of primary […]

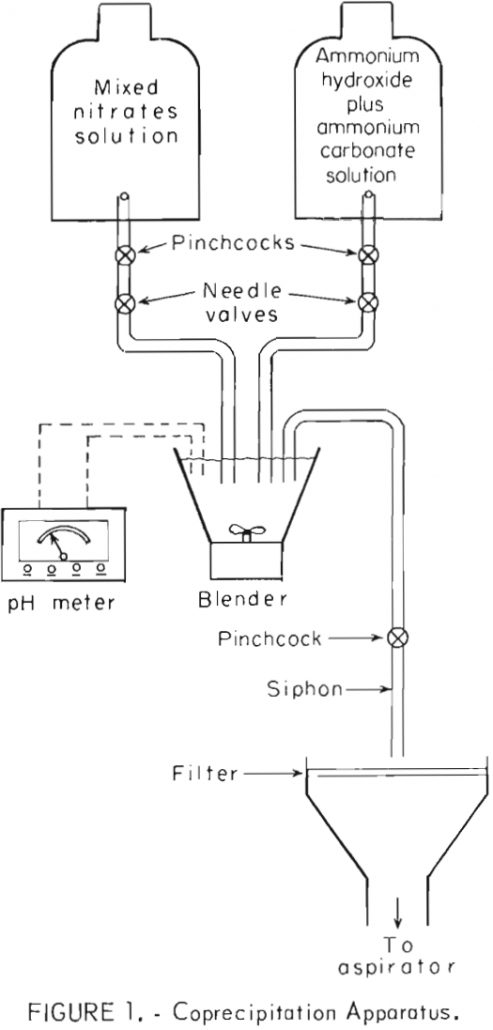

Dispersion Strengthening of Lead by Coprecipitation

This research was conducted as a part of a Bureau of Mines aim to promote more efficient use of mineral-based materials. The objective of the study was to prepare high-strength, creep-resistant lead utilizing the coprecipitation method of dispersion strengthening. The excellent corrosion resistance of lead and its sound attenuation capability, easy formability, and other advantageous […]