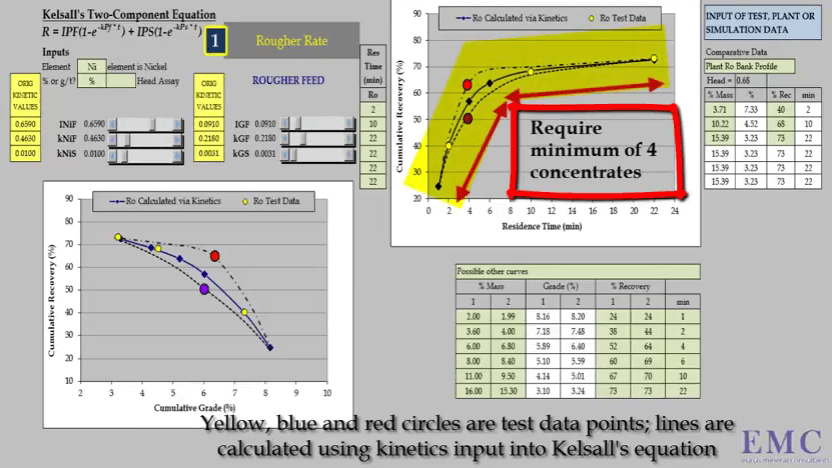

Timed Flotation Test & Cumulative Grade Recovery Curve

Apart from conducting a rate test in the correct manner, it’s important to collect the right number of concentrates and at the right times; doing this will ensure that the data you generate maximizes your analysis of flotation response. To properly define the relationship between recovery and time, you need a minimum of four concentrates […]

Gold Bullion Assay Procedure

The procedure for assay of gold bullion, as described has for its sole object the estimation of the percentage of gold present in the alloy, all other constituents being disregarded. In the first instance, the simple case of the assay of gold alloys containing appreciable quantities of only copper and silver will be dealt with. Refined […]

Parting the Assay Buttons

The assay buttons are flattened by a hammer weighing about 7 lbs., with a convex face, on an anvil kept quite bright and clean and used for this purpose only. A heavy blow is first delivered on the centre of the button, the diameter of which is thereby increased to nearly that of a threepenny […]

Weighing Gold for Assay Checks & Proofs

The balance must readily indicate differences of 0.005 per 1,000, or 1/40 milligramme, with a weight of ½ gramme in each pan. The “checks” or “proofs” (vide infra) are weighed first, and their mean excess or deficiency in weight applied as a correction to all the cornets worked with them. This may be done by means […]

How to Make Gold

The purest gold obtainable is required for use as standards or check pieces in the assay of gold bullion. The following method of preparing it is now in use at the Mint. Gold assay cornets from the purest gold which can be obtained are dissolved in nitrohydrochloric acid, and the excess of nitric acid expelled […]

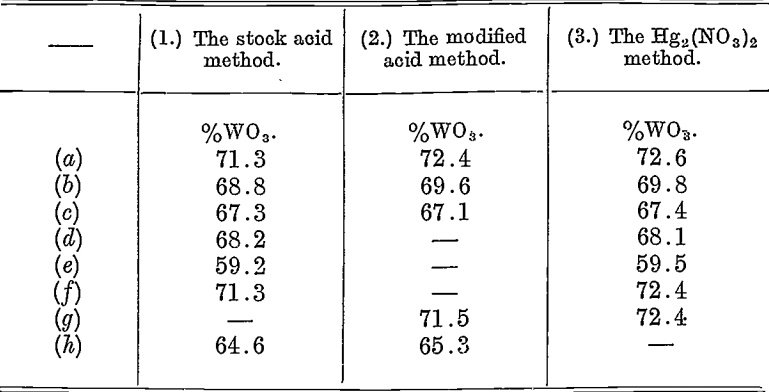

Assaying Tungsten Determination

In dealing with wolfram ores and concentrates, we identified 3 three determination methods for the estimation and Assaying Tungsten that are discussed below are well known, but these results of their trials and comparison under technical conditions may be interesting. Tungsten Assaying Method 1 The routine procedure for the assay of rich wolfram ores or concentrates […]

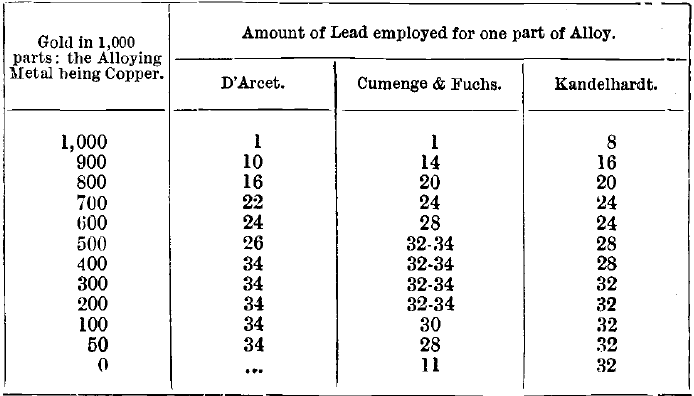

Fire Assaying Gold Alloys

It is often impracticable to apply the ordinary parting assay to the examination of low-standard alloys of gold with other metals. These are then tested by various other methods, of which a summary is given below, the alloys being grouped in four series for convenience: A. Alloys requiring scorification. B. Amalgams. C. Alloys containing members […]

Bone Ash Cupels

In order to get a preliminary view of the question of gold absorption in cupelling gold bullion, certain samples of very pure gold, which were being sent out to various laboratories in the Mint service for comparative assaying, mere assayed in sets of sis with three proofs. The nine ctipe!i were arranged in the muffle […]

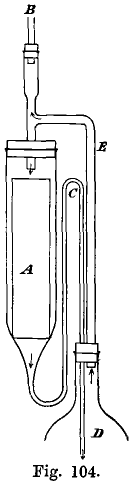

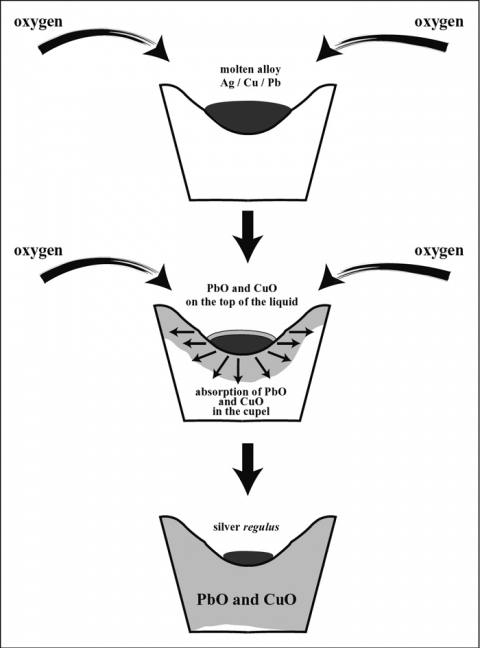

Cupellation

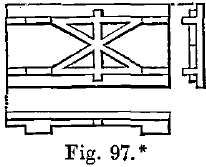

A coke Cupellation furnace still in use at the Mint is shown in front and side elevation in Figs. 95 and 96. It consists of an outer casing of wrought-iron plates about 1/8 inch thick, united by angle iron. This casing is connected with a chimney 60 feet high by means of a wrought-iron hood, a, […]

Gold Fire Assay Process

The Gold Fire Assay Process of ores is almost universally conducted in the dry procedure by furnace methods. Exceptions will be noted later. The plan of operation is to concentrate the precious metal in a button of lead either (1) Fire Assay By fusion in a crucible; or, more rarely, (2) Fire Assay By scorification. […]