XRF X-Ray Fluorescence

X-ray fluorescence or XRF is an analytical technique that has been used for many years to determine the elemental composition of a wide variety of materials. Examples include metal alloys, minerals and petroleum products. X-rays form part of the electromagnetic spectrum. They are on the high energy side of the ultraviolet and are expressed in […]

Principle of XRF & XRD

But first, I want to start with a basic Principle of XRD and XRF technology and how they are similar and how they differ. So, what is X-ray fluorescence? Very simply put, X-ray fluorescence uses an excitation source to excite elements, electrons within an atom. This excitation will eject an electron from its orbital, and […]

Laboratory Leaching Test Procedure

Laboratory Leaching tests of mine wastes are typically performed using procedures that fall into two basic categories: batch and continuous. These categories are analogous to batch and continuous reactor methods used in metallurgical processing. Batch reactors for leaching tests can be in the form of a closed vessel, a cell, or a column. A continuous […]

Laboratory Regrind Mill

A laboratory stirred ball mill was used in a batch manner, with the milling time being varied so as to produce a number of different product size distributions diameter ratio of one, and has a jacket through which cooling water is passed. The vessel is mounted on a turntable which is located on a thrust bearing. The turntable is restrained […]

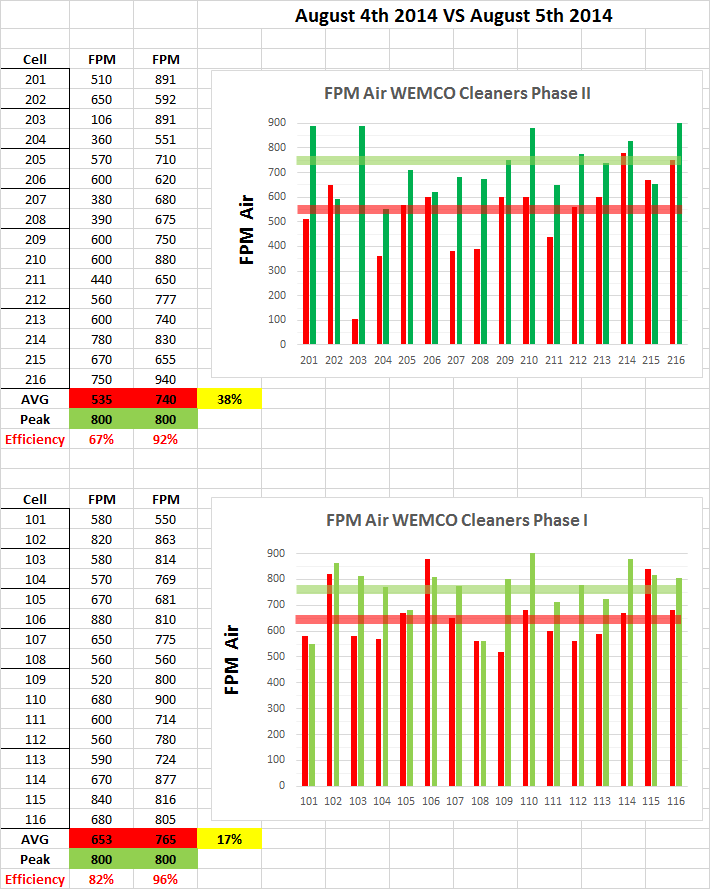

Anemometer to Measure Air Flow Self Aspirating Cell

I once used an Anemometer to Measure Flotation Cell Air Flow on Self Aspirating WEMCO machines. Overtime, operations & maintenance got lazy and never took care of cleaning the airflow supply pipe into the cell. It was clear flows were partially to completely blocked. I improvised the method and now found one the US Bureau […]

How to Determine Power Input in Laboratory Ball Mill

In the study of ball mill grinding at the International Experiment Station of the United States Bureau of Mines at Salt Lake City, Utah, it was desirable to measure the work input to a ball mill at the mill itself so that consideration of motor efficiency and transmission losses would be eliminated. The device adopted […]

DIY Fire Assay Home Laboratory Microwave

I have always been amazed at the amount of knowledge the Alchemists in the Middle Ages possessed regarding chemistry, metallurgy and the precious metals. Yet they did not realise that the fleas of rats were transmitting the plague that killed literally millions of people in Europe during the 1300’s, nor that the earth was round. […]

Ball Impact Spalling Wear Test

Many types of ore crushing and grinding equipment, such as hammer mills, rod mills, and ball mills, subject wear parts to repetitive impacts. The wear that results from fatigue, spalling, chipping, and fracturing can be more severe than abrasive wear. This is especially true of very hard alloys such as martensitic steels and alloyed white cast […]

High Speed Impact Gouging Test

A new and promising method for transporting raw materials from a mine is by pneumatic pipeline. This method uses a flow of air to transport solid particles of rock or ore through a pipeline. Lifting ore from underground to the surface pneumatically has great economic potential but is limited by severe wear problems. Pneumatic conveying […]

Pin-on-Drum Abrasive Wear Test

The pin-on-drum abrasive wear test involves high-stress, two-body abrasive wear. One end of a cylindrical pin specimen is moved over an abrasive paper, abrading material from the specimen and crushing the fixed abrasive grains. The wear is believed to simulate wear that occurs during crushing and grinding of ore-processes in which the abrasive particles are […]