Ball Mill Wear Test

When a lump of ore is crushed by the impact between two balls in a ball mill, it is considered high-stress, three-body abrasive wear. The abrasive wear of balls that results from the milling of ore is the major wear loss in most minerals processing plants. During the wet milling of ores, abrasive wear is […]

Jaw Crusher Gouging Abrasion Test

Gouging wear occurs in many mining operations , for example, where excavator teeth or loaders penetrate or drag over rock, and in jaw and gyratory crushers. Gouging wear is identified by the removal of a significant amount of material (a gouge) from the wear object after an encounter by the abrasive object in which the […]

Low Angle Slurry Pot Test

Transporting minerals as a slurry is an efficient means of transportation and is done during many mineral beneficiation processes. However, the movement of slurries can cause significant wear to the slurry-handling equipment, especially in places where the flow changes direction. Wear caused by slurries is an economic concern of industry. Pumps, elbows, tee junctions, and […]

Elevated Temperature / Dry Particle Erosive Wear Test

Many industrial materials are subject to high-velocity abrasive particles at elevated temperature. Wear of this type is found, for example, in hot dust collection equipment. In order to select and develop materials for high-temperature use and to study the basic mechanisms of hot erosion, a laboratory test is necessary. Much has been learned about erosion […]

Dry-Particle Erosive Wear Test

Dry-particle erosive wear can be classified as low-stress, two-body wear, the same type as in the preceding test. It simulates the wear conditions that occur in pipes, cyclones, and other equipment that carry fly ash or other particulate matter in a gas stream. A standard practice for conducting a dry-particle erosive wear test has been […]

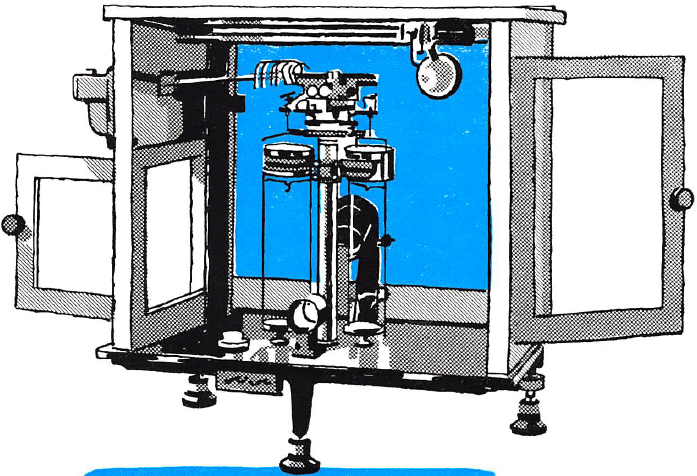

Taber Abraser Test

The Taber Abraser is a commercial wear tester designed to test the abrasive wear resistance of flat specimens of a wide variety of materials including coatings, paints, metals, plastics, paper, textiles, ceramic tile, and etched or printed material on glass. The wear condition can be classified as low-stress, two-body abrasive wear. The model 505 Taber […]

DSRW Abrasive Wear Test

The dry-sand, rubber-wheel (DSRW) abrasion test apparatus simulates low-stress, three-body abrasive wear. This type of wear occurs in the mining industry in linkages, pivot pins, and wire ropes, which suffer slow wear from the sliding and rolling action of abrasive fragments of rock and ore trapped between metal surfaces. Because this type of wear is […]

Wear Testing Laboratory

The laboratory wear testing capabilities are described. Wear tests are used to support the group’s research efforts toward reducing the wear of equipment used for mining and minerals processing and any wear involving a loss of strategic or critical materials. The emphasis is on abrasive wear because it accounts for most of the wear losses […]

Ferrocyanide Methods of Analysis & Assay Procedure

QUALITATIVE DETECTION Because of the distinctive colors of the precipitates formed, various cations have been proposed for the qualitative detection of the ferrocyanide ion. Since interference frequently occurs, some care is usually necessary. As an illustration, the following condensed procedure serves for the detection of the ferrocyanide ion in the presence of ferricyanide and thiocyanate: […]

Copper Nickel Flotation

The Bureau of Mines investigated the flotation responses of two copper nickel ore samples from the Duluth Complex with the objective of recovering bulk sulfide concentrates. One of the ores studied was taken from a test pit; the other was taken from a test shaft. The samples were quite similar except that the pit sample […]