How to Remove Mercury from Copper Concentrate

The copper-silver-mercury orebody of Gortdrum Mines (Ireland) Limited is located 3 miles north of the town of Tipperary in the Republic of Ireland. The first shipments of concentrates were made to the smelter in Europe in late 1967. In the spring of the following year, word was received from the smelter that these early shipments […]

Overcome Environmental Problems in Sinter Plants

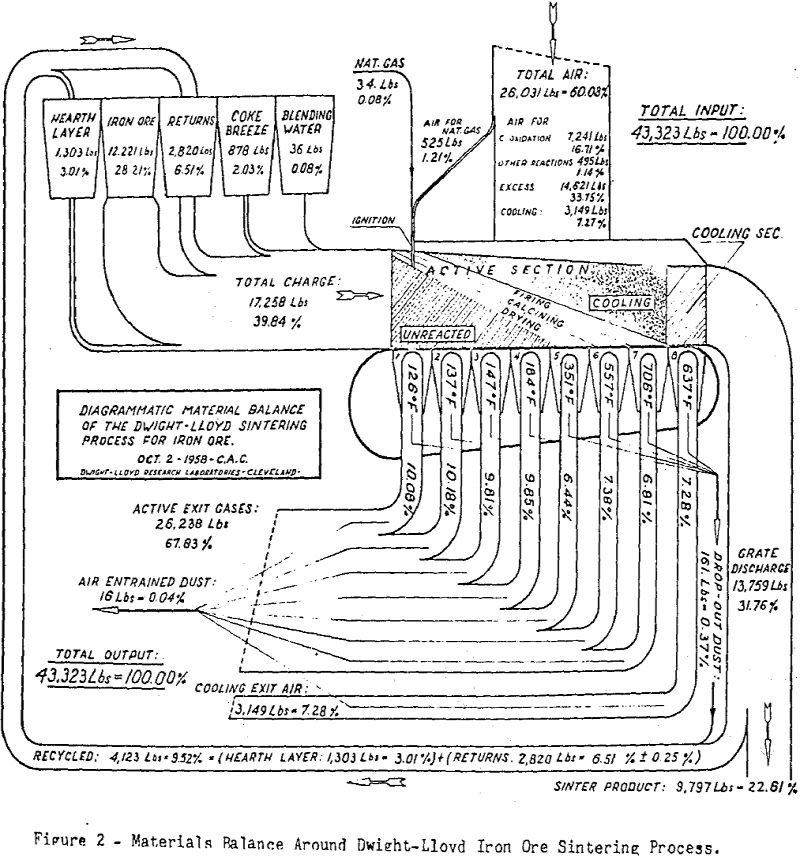

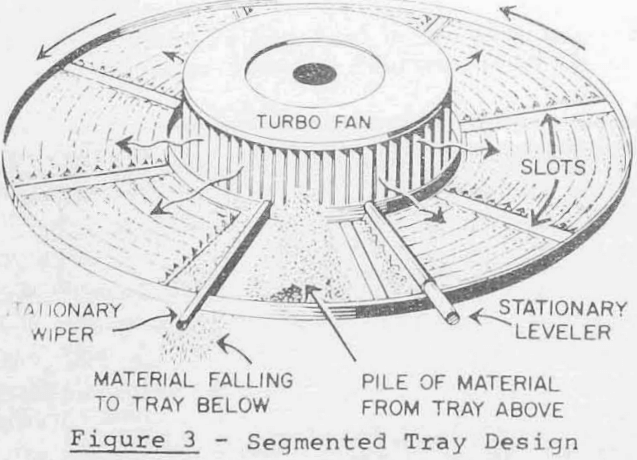

The continuous sintering process was invented more than 60 years ago by two metallurgists, Arthur S. Dwight and Richard L. Lloyd, who saw a need for automation in mineral processing. Their specific objective was to beneficiate copper ore by desulfurizing and agglomerating it for copper blast furnace smelting at the Cananea plant in Mexico. Since […]

Coal Drying Methods

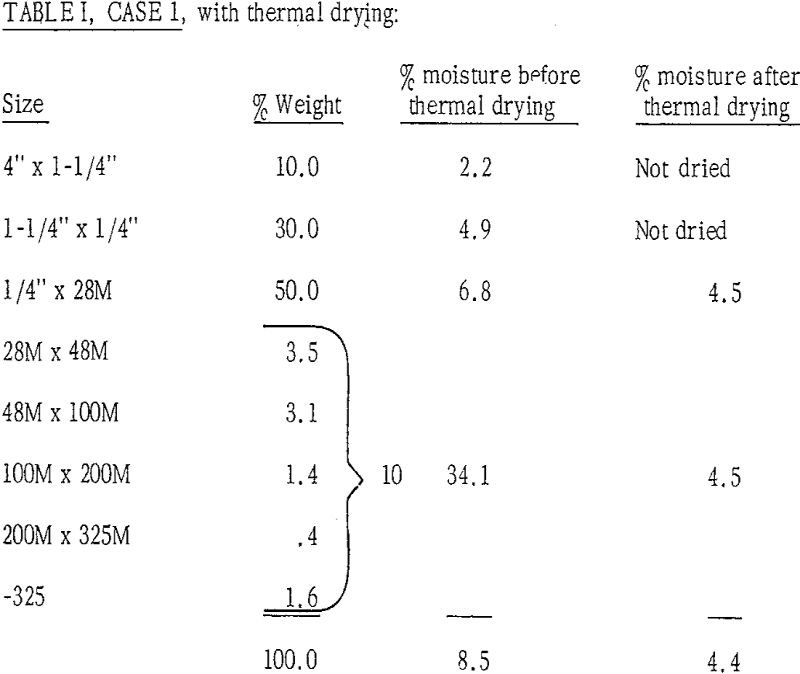

In the past, it has more or less been a general rule that any time the total product is being washed, both mechanical and thermal drying was required. The reason for this was that a product moisture of 3 to 4% was required and thermal drying was and is the only practical method by which […]

Blue Flame Burner

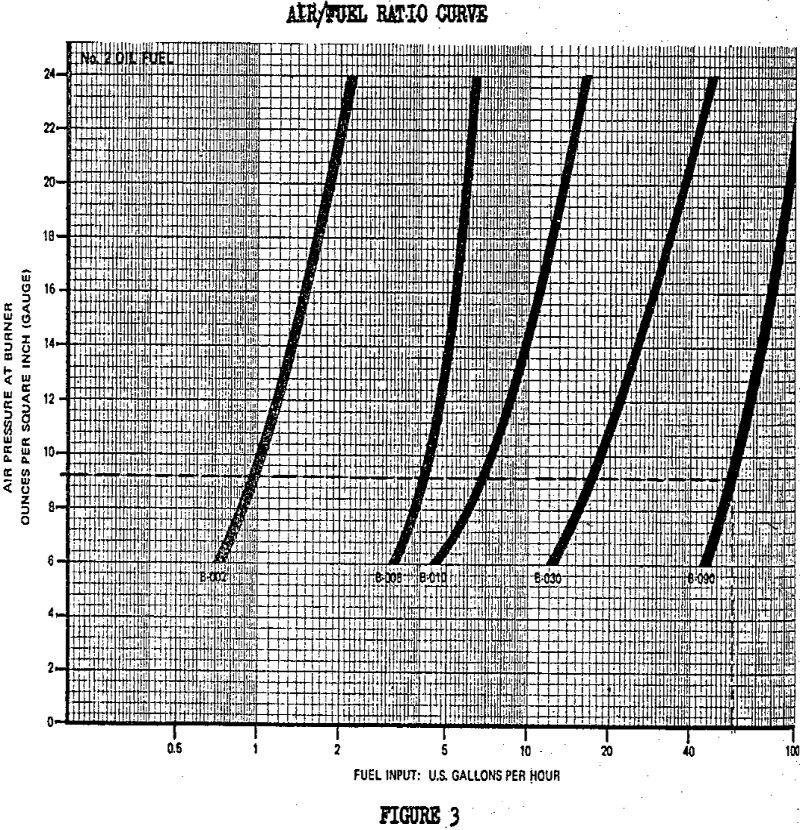

You have all seen a gas stove. Gas burns with tiny, bright-blue cones of flame; they are very hot, very clean, very quick to burn. You have also seen a hardwood fire; when the yellow flame disappears, the charcoal gives off a bright blue, almost transparent flame. Again, this flame is hot, very clean, very […]

Coal Fired Lime Kilns

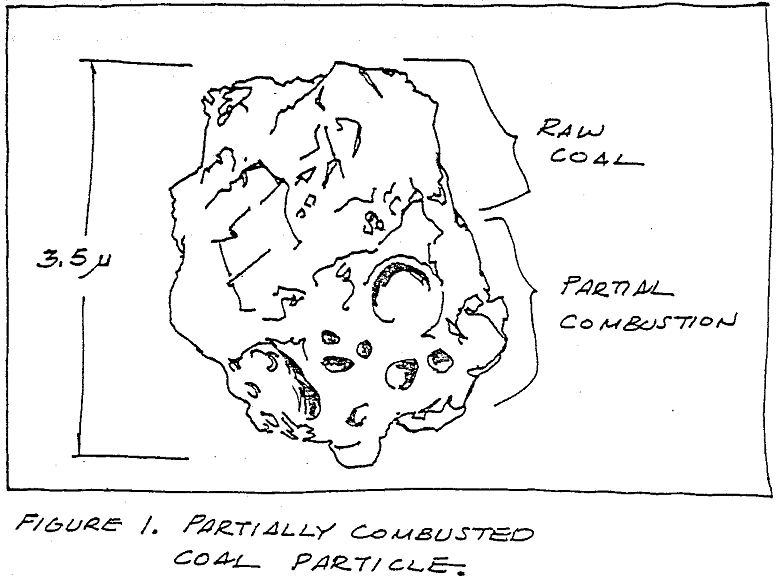

The combustion of pulverized coal is a century-old practice. Many people have investigated coal dust and the residual fly ash particles that remain after combustion. But the combustion process and fly ash formation mechanism are not understood. Working at our Maysville, Kentucky lime plant, the Dravo Lime Company Research team has collected samples of partially […]

How Rotary & Spray Drying of Copper Concentrate Compares

The rotary drying system consists of a final concentrate thickener to dewater the slurry to about 60%-70% solids; a vacuum filter (disc or drum) with the necessary vacuum pumps to dewater the thickened material further to about 14%-20% moisture on a dry basis; a collecting belt underneath the filter to receive the filter cake; a […]

Drying & Calcining Ammonium Diuranate

‘Yellow cake’, so named because of its inherently bright yellow color, is a finely divided precipitate that can be formed after the leaching step when refining uranium ores. Feed solids enhancement then occurs to at least 50% by weight using filters or centrifuges. This is followed normally by drying and then calcining with the conversion […]

Sinter Plant Operation

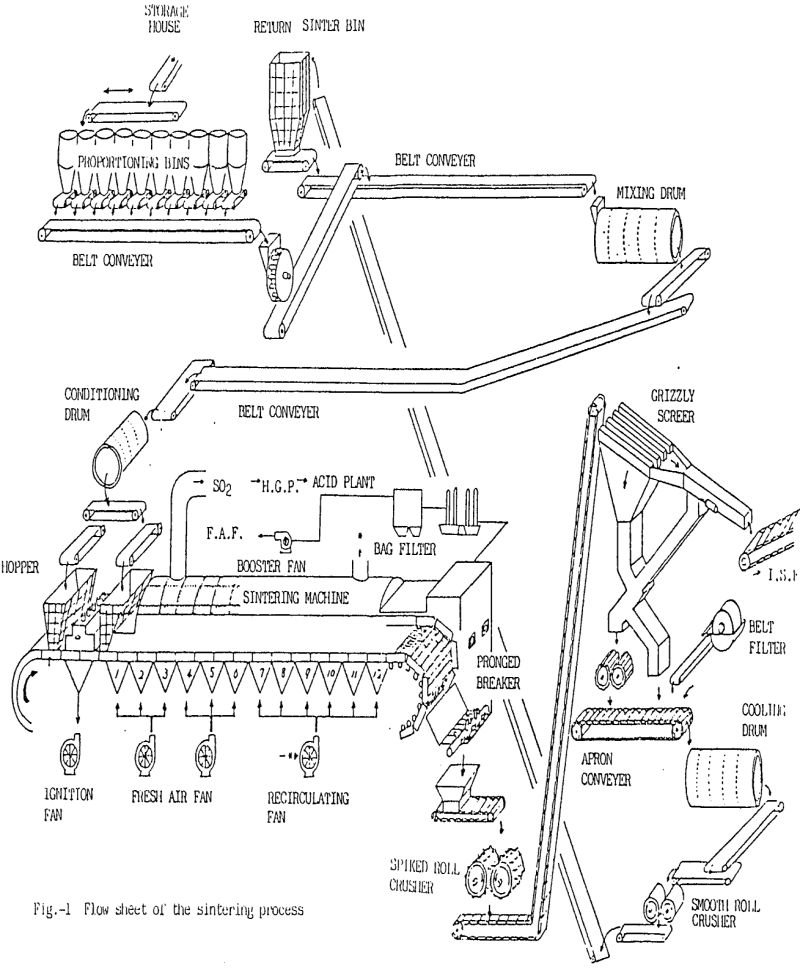

The sintering process for the preparation of raw materials to be fed to the Imperial Smelting Furnace (I.S.F.) is rather diversified in its characteristics. In comparison to the other preparation process for zinc extraction, i.e., fluidized bed roasting, the sintering process enables the Imperial Smelting Process (I.S.P.) smelter to treat a variety of raw materials. […]

Kivcet Process

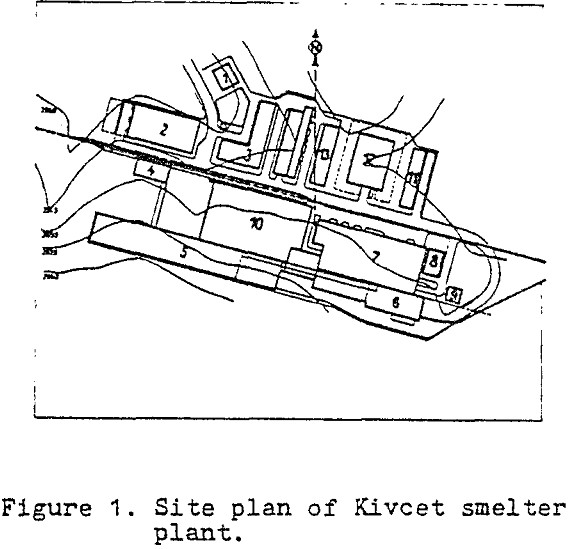

It has long been recognized that the conventional method of producing lead bullion from concentrates via the sinter-blast furnace route presents problems in meeting the tight regulations for environmental protection which have been introduced in many countries. As described by Chaudhuri and Melcher, 1978, this has led to the development over the past decade of […]

Electric Smelting and Refining of Lead

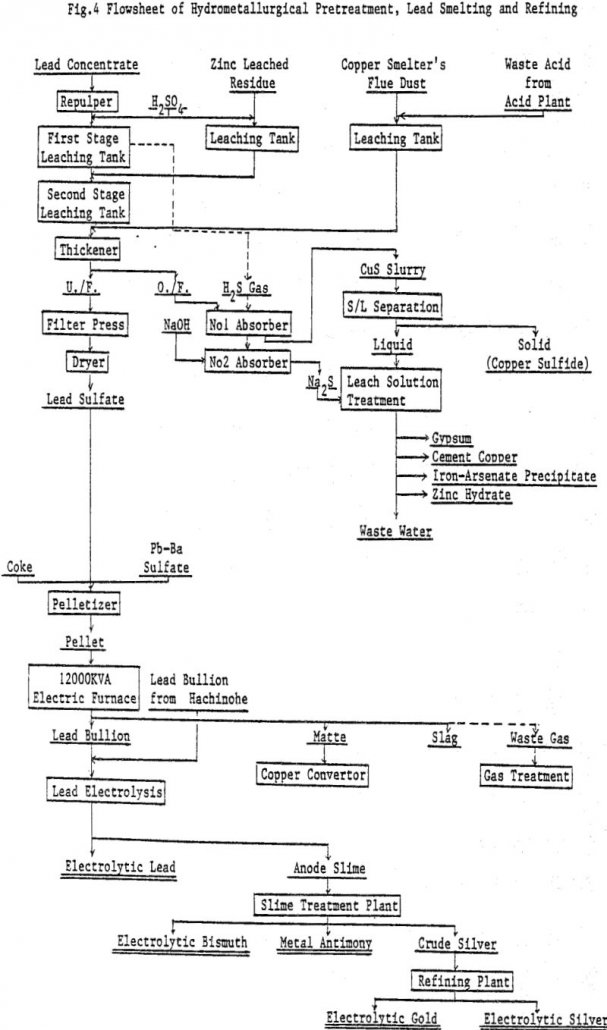

Lead concentrates from Kuroko (black ore) mines, which contain Cu 4 – 7%, Pb 55%, Zn 3 – 7%, As 0.5 – 0.9% are treated by hydrometallurgical process in order to smelt the product by electric furnace smelting together with other lead resources from Kuroko. The hydrometallurgical pretreatment involves sulfuric acid leaching at first stage, ferric […]