Burning Magnesium and Aluminum to get Refractory Material

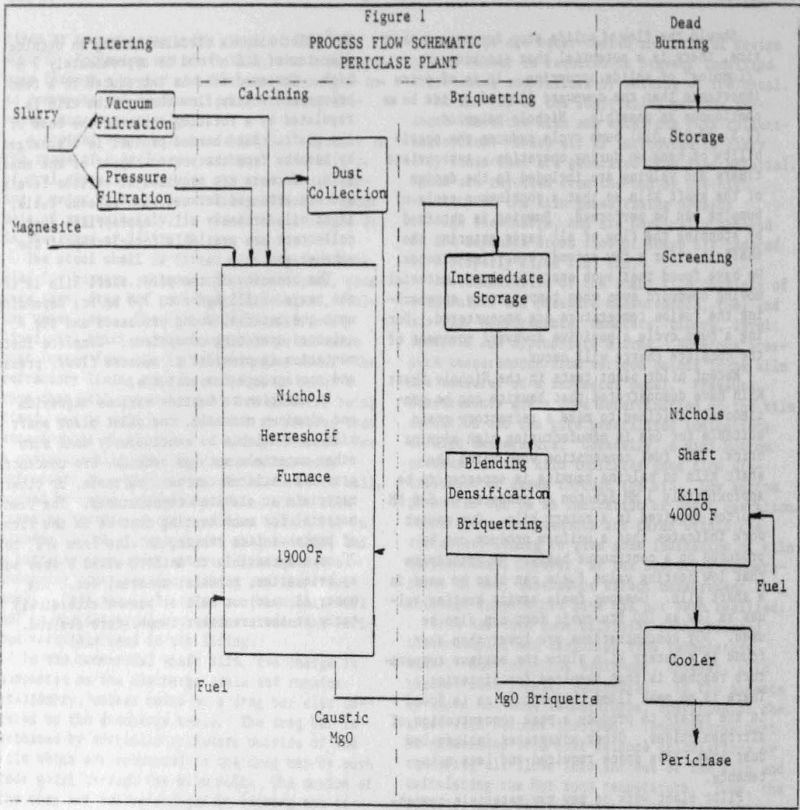

Bauxite, dolomite, and magnesite are natural occurring minerals that are used extensively in the manufacture of refractory products. In addition, magnesia produced from seawater or brine finds its way into the production of refractories. All of these materials must be processed at high temperatures, 1500°C to 2200°C, to produce an intermediate raw material (refractory grain), […]

Grate Kiln System

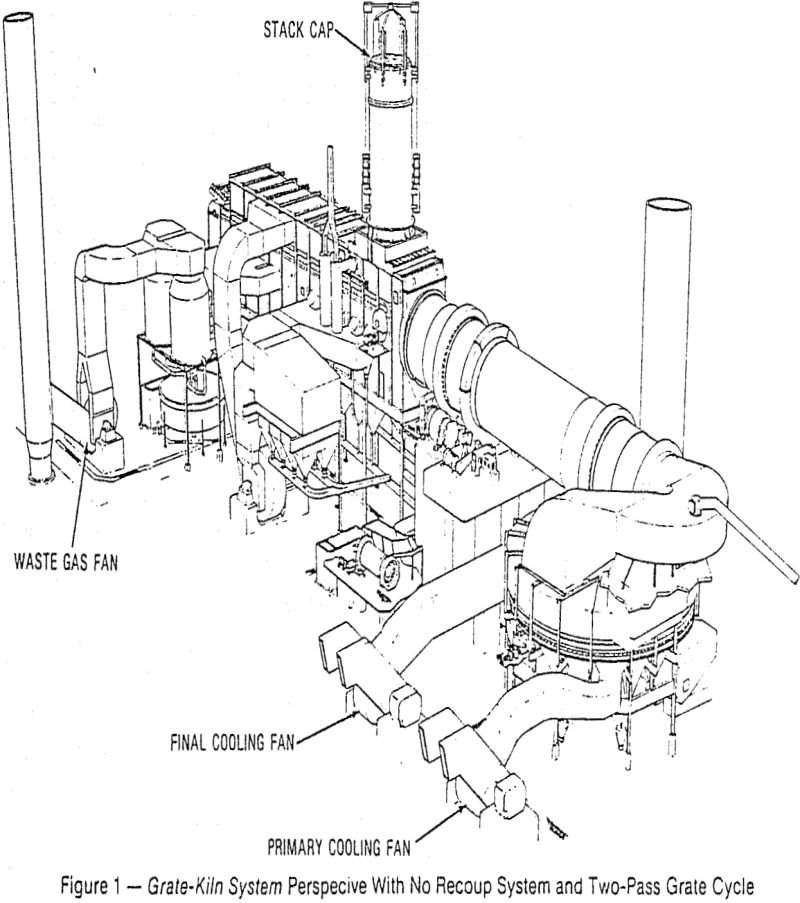

The economics of pellet plant operation, in terms of fuel and power consumption, flexibility in the selection of the cheapest fuel source, system availability, maintenance costs, and the simplicity of process design, contribute to the determination of building and profitably operating a pellet plant. Design innovations, supported by actual field data, have been initiated into […]

Direct Fuming of Zinc in Sulfide Ores & Concentrates

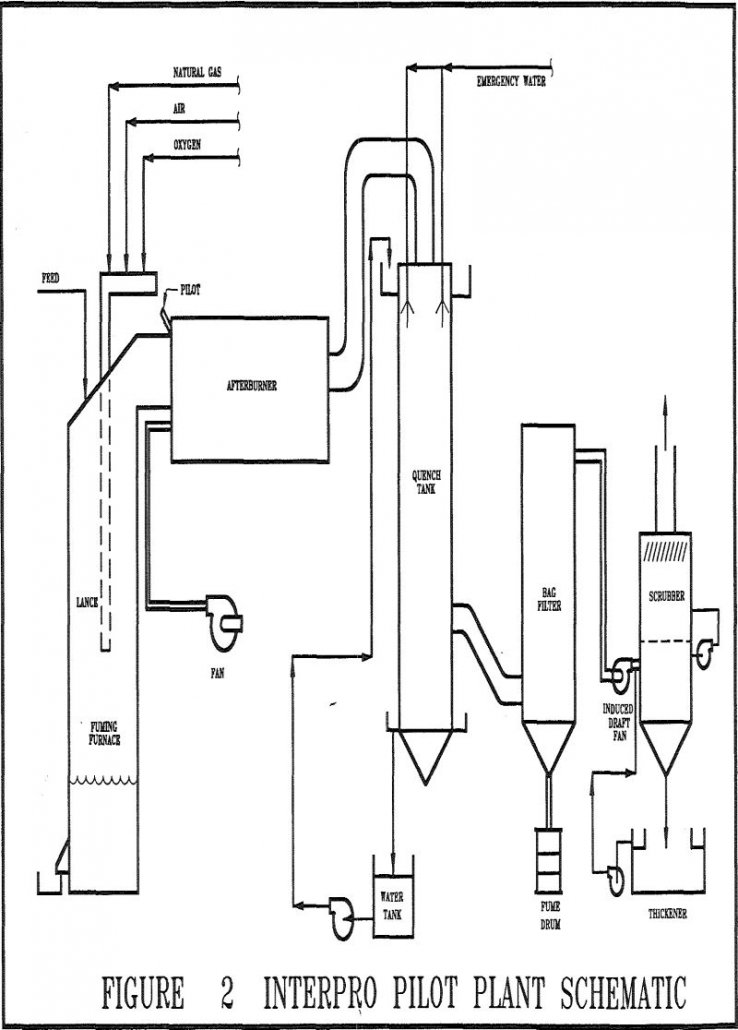

Minproc has developed a process concept of preconcentration of zinc and tin to moderate grade preconcentrates at high recovery, followed by pyrometallurgical upgrading (filming) of the preconcentrates to high grade, saleable oxide fumes. Broadly, concentrate grade is inversely proportional to recovery, and while high recoveries of zinc and tin can be achieved into low grade […]

Flash Smelting Process

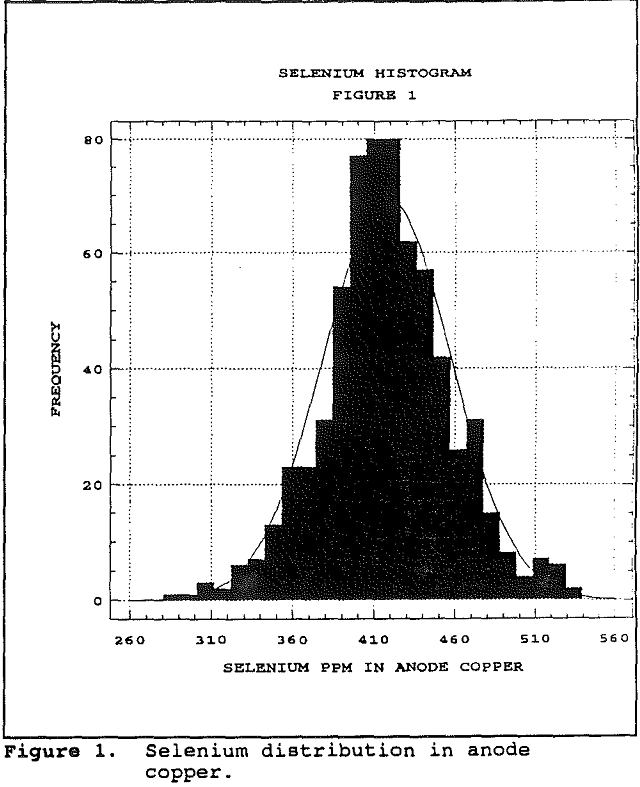

Process Flow Description: Concentrates and other copper bearing material are blended and conveyed from two separate areas of the plant to three 464 ton capacity wet charge bins located above the rotary dryer. Flash furnace silica flux is conveyed to a 250 ton capacity fine flux bin located adjacent to the wet charge bins. The concentrate […]

Segregation Process for Treatment of Copper-Cobalt Oxide Ore

The segregation process has been known for many years and applied industrially for the treatment of various refractory copper ores. The principles of the process are briefly reviewed; the process was tested in the laboratory on two copper-cobalt oxide ores from Gecamines, Shaba Province, Zaire. Various parameters of the process, such as segregation temperature, dosage […]

Atmospheric Elution Process

Acid-washed carbon is loaded into the top of the column from a feed vessel and allowed to rill into the feed hopper. The carbon flow from the feed vessel is automatically choked and will only feed as carbon is withdrawn from the base of the column. There is sufficient surge capacity in the feed hopper […]

Nonconventional Fluid Bed Drying

Drying System Design The fluid bed dryer has been designed for the specific requirements of drying a 6 mm x 0 (¼” x 0) feedstock of anthracite culm and occasional intermittent feeds of anthracite silt. The feed moisutre of the culm ranges between 16 and 18 per cent by weight and is approximately 24 per […]

Ceramic from Ilmenite & Zircon

The direct conversion of mineral concentrates into useful ceramic materials, without several intermediate processes, is of great interest to the materials community. Recently there has been increased interest in producing ceramic powders with very small sizes (in the order of nanometers) starting with mineral precursor. Thermal plasma processing of mineral concentrates may be used to […]

Continuous Elution for Extraction of Gold from Carbon

The continuous elution process is a continuous counter-current system operating in a pressure vessel at elevated pressure and temperature in which both carbon and the eluate are simultaneously moving through each other in opposite directions. During this process the carbon particles enter the top of the vessel loaded with gold and exit barren through the […]

Recycle Superalloy Scrap Metals

We treated mixed and contaminated superalloy scrap by pyrometallurgical and hydrometallurgical methods to separate and recover metal values. Best results were obtained by leaching Zn-treated or atomized scrap with HCl-O2 at 95° C and 50 psig O2. This resulted in dissolving approximately 98% of the Al, Co, Cr, Cu, Fe, Mn, Ni, and Zn while […]