Pellet Cold Bonding

This paper describes the production of cold or low temperature bonding method using sponge iron powder as a binder for iron bearing material after balling. Development of cold bonding pellet methods Theoretical foundation of the cold bonding pellet method The bonding mechanism of cold bonding pellets using sponge iron powder as a binder is based on […]

Hydrothermal Boehmite Precipitation

The currently proposed method for the recovery of alumina from nonbauxitic materials involves acid leaching (Figure 1). Primary emphasis is on kaolin clays. To date, leaching by nitric acid, hydrochloric acid, and sulfurous acid has been considered, and it appears that leaching with hydrochloric acid (25-27%) is the most practical process. The first step in […]

Extracting Lithium

The Federal Bureau of Mines investigated extraction of lithium from non-conventional resources in keeping with its goal of maximizing minerals and metals recovery from domestic resources in order to assure an adequate supply of minerals to meet national economic and strategic needs. This report describes the results of bench-scale studies on the processing characteristics of […]

Flux Lime

All forms of “lime” are used in the steel plant. Calcium hydroxide is used for water treatment, acid neutralizing, and as a lubricant for wire drawing. All the other limes are used as fluxes in the sintering plant, blast furnace or steel producing furnaces. In the production of self flux or super-flux sinter, high calcium […]

Centrifugal Casting of Refractory Concretes

As part of its program to conserve the Nation’s natural resources by developing improved performance materials, the Bureau of Mines, U.S. Department of the Interior, in cooperation with the U.S. Department of Energy, has conducted an investigation of materials of construction able to withstand the high temperature and hostile environments encountered in coal gasification units. […]

Fine Gold Recovery & Refining

How to Remove Copper from Fine Gold Prevention of copper entering the final bullion has been the principal objective of all experimental work performed on zinc slimes in the goldroom. Above all other metals encountered during treatment, it is the most difficult to separate from gold and silver. Broadly, two methods are possible for elimination […]

Gold Refinery Procedures

Before processing by the gold refinery, gold can be extracted from ore by the following series of operations: Coarse crushing; Fine grinding; Straking for free gold; Flotation; Concentrate roasting; Straking for free, gold; Cyanidation of concentrates; Precipitation of gold from cyanide solution. The last operation is performed in a Merrill-Crowe radial leaf type precipitator, to […]

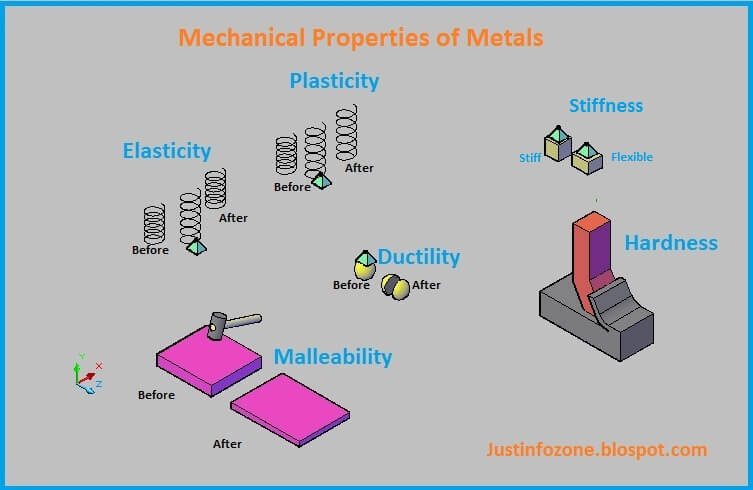

Mechanical Properties of Metals

In a recent discussion of Dr. Jeffries’ paper on tungsten, J. C. W. Humfrey, after taking exception to certain of the author’s ideas relative to the cohesion of A and C metal, expresses the opinion that future research is likely to develop a method of preparing tungsten possessing “mechanical properties in line with those of […]

Zinc Vapor Condensation

The study of the condensation of zinc from its vapor was undertaken to shed light on certain problems encountered in large-scale electric zinc-furnace work recently conducted. It is a matter of common knowledge that one of the disadvantages of the arc type, electric zinc furnace, is the production of a large amount of blue powder […]

Electric Gold Melting Furnace

The furnace described in this paper was installed and has been used by the writer for the melting of rich gold-bearing material, and has given complete satisfaction. It may, therefore, prove of interest to other metallurgists who are faced with a similar problem. A furnace of this type should be most suitable for the reduction […]