Pellets for Direct Reduction

The iron ores mined by LKAB in the north of Sweden have excellent beneficiation properties. This gives LKAB a favourable position as regards the production of low silica pellets for direct, reduction. LKAB have concentrated on developing and marketing grades of pellets for the Midrex-Purofer-Hyl process group, i.e. such D.R. processes which are carried out […]

Grate-Kiln Operations for Better Pellet Quality

This paper describes some of the latest improvements that have been incorporated or planned by the Cleveland-Cliffs Iron Company to reduce operating costs and improve pellet quality. The Cleveland-Cliffs Iron Company operates and manages mining, beneficiation, and pelletizing operations in Michigan, Canada, and Western Australia. Operating/Maintenance Cost Savings Cleveland-Cliffs Iron Company, in December, 1976, embarked […]

High Porosity Pellets

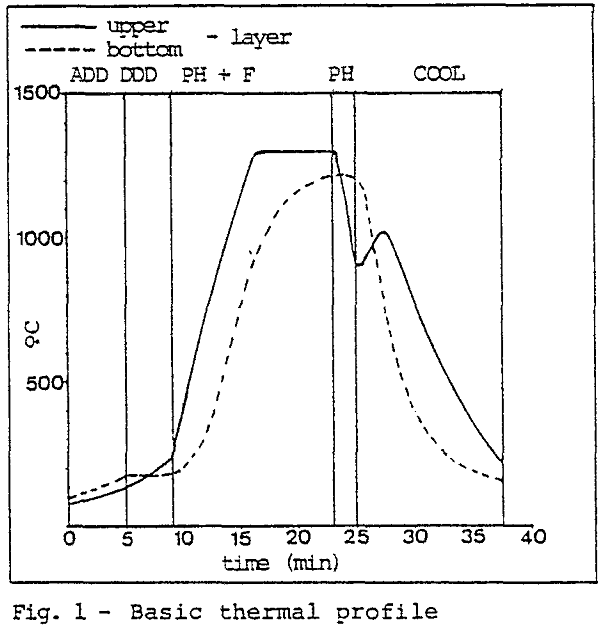

Since the petroleum crisis in 1973, the effect of the energy cost in the pellet production has been very severe with great risk to this economic activity. The countries that import petroleum, specially those under way of industrialization, felt a great impact in their payment balance due to the high expenses in oil. The testwork has […]

Crushed Pellets

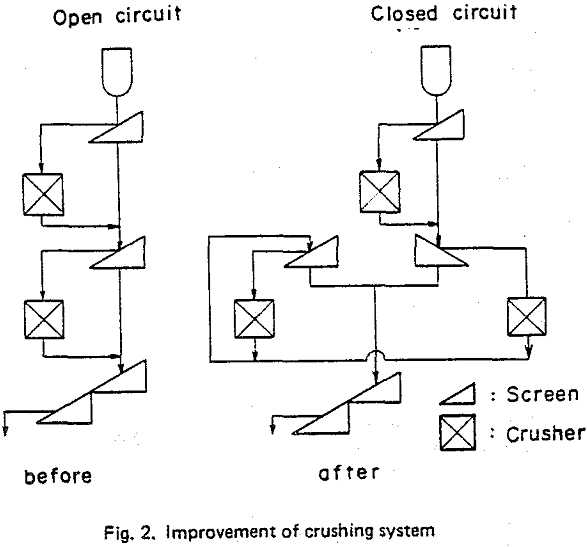

At the Kakogawa works of Kobe Steel. Ltd., the agglomeration facilities are composed of a pelletizing plant and sintering plant. This aim is to utilize raw materials efficiently and stabilize the raw material resources. Therefore at Kakogawa works, the blast furnaces (BF) have been operated with high pellet ratio and various developments for pellet properties […]

High MgO Blast Furnace Pellets

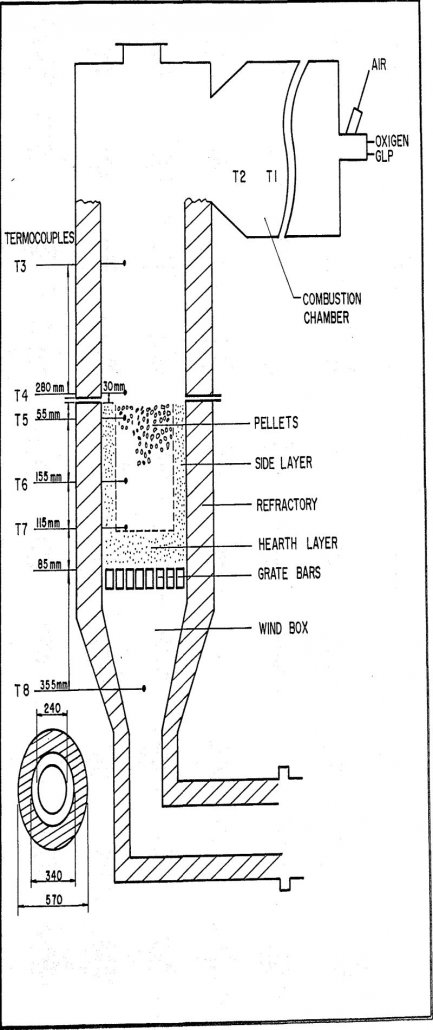

The pellets were produced in the pilot plant, and followed the steps bellow: – Definition of pellet chemistry – Model for high MgO blast furnace – Pellet production run Pellet chemistry was defined based on the fact that high MgO levels have the capacity to attain improved softening and melting characteristics. Therefore the chemical properties […]

Iron Ore Pelletizatton Layering Mechanism

Pelletization is the unit operation of agglomerating moist particulate materials by tumbling in horizontal rotating drums or inclined discs. Pelletization has extended the life of iron ore industry by enabling the treatment of low grade iron ores which are available in large reserves through out the world. Iron ore pelletization is a two step process […]

Ferrosilicon in Dense Medium Separation

Aqueous polydisperse suspensions of angular (milled) or spherical (atomised) ferrosilicon alloy powders are widely used in mineral, aggregate and scrap separation processes as a dense medium. Table I shows the typical range of Dense Media Separation water analyses (analysing the supernatant after allowing the ferrosilicon solids to settle) taken from three diamondiferous-kimberlite circuits, from which it […]

Mineralogical from a Smelting Reduction Ironmaking Pilot Plant

The American Iron and Steel Institute (AISI) has conducted major cooperative research efforts with the United State Department of Energy (DOE) and industrial organizations since the autumn of 1988 on the development of a process for direct steelmaking. This research has been inspired by the fact that the direct iron reduction smelting process holds several […]

Iron Ore Beneficiation Process

During the last ten years great strides have been made, on the Mesabi range, in the practice of beneficiating low grade iron ore material. By beneficiation is meant all methods of removing impurities, and raising the iron content to a point where it can be sold in open market, the principal impurities being silica and […]

Types of Welding Process

The general object of the investigations has been to extend the use of welding in the construction of merchant ships and, specifically, to provide a definite basis for obtaining the best economy and efficiency in employing welding in place of riveting in the construction of the hulls of such ships. The extent of the field […]