Touchstone Gold Tester

There are three methods for ascertaining the quality of gold, viz., by the touchstone and needles, by cupellation, and by parting or quartation. The first is the process which, from its simplicity and convenience, is used by jewellers and others for learning at a glance the value of the articles which they buy and sell, […]

Melting Gold

For melting gold, a strong fire is necessary, and the operation is generally performed in a forge or furnace. The following is a description of a new form of furnace, invented by the author, and which is admirably calculated for melting in crucibles, for the distillation of mercury, for cupellation, and for every other chemical […]

California Gold

Having lately analyzed three specimens of ore from California, all of which were supposed by the possessors to contain gold, and finding but one of them that proved to contain it, I am convinced that the native gold is found in the same localities as some worthless ores, having a yellow colour, and which are […]

Electrolytic Method for Recovery of Lead from Batteries

Low Temperature Properties of Tin and Tin-lead Alloys Add see Leaching and electrochemical recovery of copper, lead and tin from scrap printed circuit boards.

Coal Beneficiation Technology

So far in this module we’ve looked at how coal or minerals are found and how they are mined. In this topic we will look at the next step in the process that is upgrading the mining material to increase the concentration of the value of the component, before it is then transported to the […]

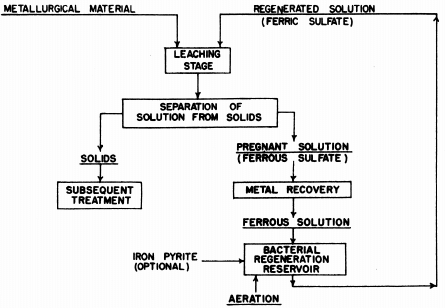

Bacteria Leaching Low Grade Ores

USING BACTERIA to leach and recover a metal from any metallurgical raw material with a ferric sulphate sulphuric acid lixiviant has been patented by Kennecott. Kennecott Copper Corp. just recently obtained a U.S. patent on bacteria leaching of ores containing sulphides and/or iron sulphate. According to Stuart Zimmerley, director of research and one of the […]

Arsenic Recovery

The arsenic trioxide produced in roasting is collected in chambers, where it deposits on cooling, some 10,000 cu. ft. being allowed per ton of arsenious oxide per 24 hours. At South Crofty mine, Cornwall, these chambers are partitioned, so that the flue gases pass through some 400 ft., having a cross-section of 3 ft. by […]

The History of Grinding

Start following 911Metallurgy’s Linkedin page to get a free (my used) hardcopy of: The History of Grinding by Lynch & Rowland I will select a winner from All the Company’s Followers on November 26th 2016 and announce the winner on 911Metallurgy’s Linkedin page CLICK BELOW ON FOLLOW Contact via Linkedin will be attempted with the winner and […]

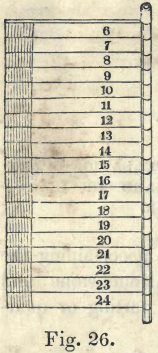

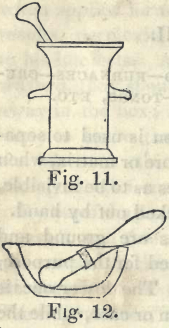

Gold Refining Crucibles

The guard pot placed for safety under the white pot and afterwards used for remelting the refined gold, is a plumbago crucible 8 ¼ inches high, 6 inches inside diameter, 5/8 of an inch thick at the top, and ¾ of an inch at the bottom, which is flat inside and stands on a cylindrical firebrick […]

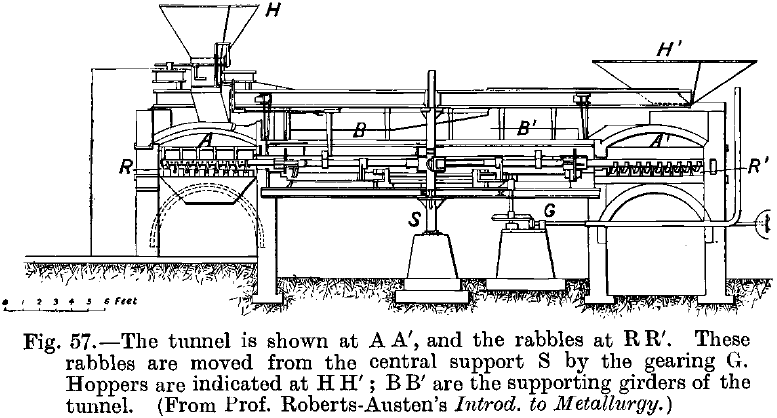

Mechanical Types of Furnaces used in Metal Industry

The furnaces which have been designed with the object of saving the labour necessary to work the reverberatory furnaces may be divided into four classes: Stationary hearth furnaces, supplied with iron hoes moved by machinery by which the ore is rabbled. The O’Hara, Spence, Pearce Turret, Brown, Ropp, Edwards, Merton, and other furnaces are examples […]