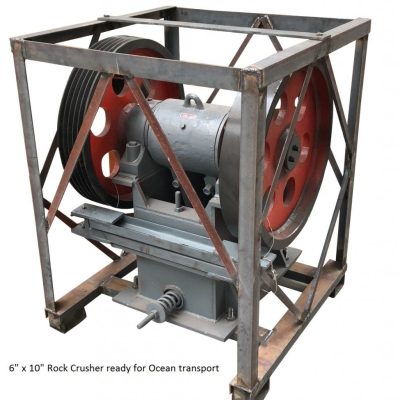

Our Large Industrial Rock Crushers employ two planer-crushing surfaces set at a small angle to each other and convergent downward. One plane is fixed and the other is pivoted either top or bottom allowing a reciprocating motion when pushed by a pitman-toggle arrangement activated by an eccentric drive.

The 3 common variations of the jaw crusher drive system are described here.

The Blake features a double toggle jaw crusher drive mechanism which gives relatively smaller movement at the receiving end of the chamber generating a powerful crushing action for large rock pieces. A refinement on the crusher illustrated is the use of a curved jaw plate on the swing jaw which renders the crusher non-choking. This curvature decreases the effective receiving opening but does prevent choking and thereby increased capacity. A high-capacity Blake has subsequently been manufactured which has a decreased crushing angle and several altered structural design details. This type of crusher is now more commonly installed unless the prime objective is to have a maximum receiving opening for hard and coarse feed.

The single toggle jaw crusher is similar to the Dodge type in that maximum movement is at the receiving opening but in all other respects compares with the Blake type. The actual crushing motion is somewhat complicated consisting of vertical as well as horizontal components. The machine is popular for its simplicity, lightweight, moderate cost, and ease of adjustment as well as its high capacity and high reduction ratio. It is particularly applicable for portable crushing rigs. Its disadvantages are the high wear of jaw plates due to the vertical component of movement and its vulnerability to bearing damage due to shock loading.