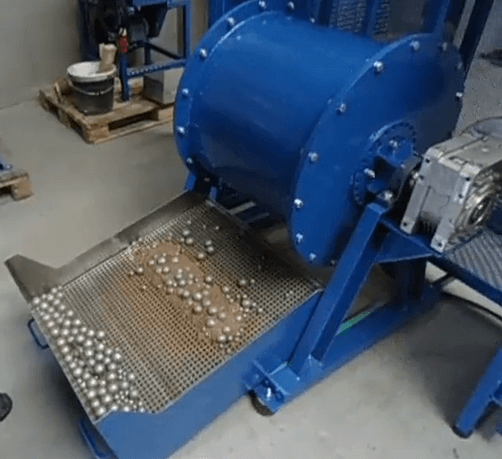

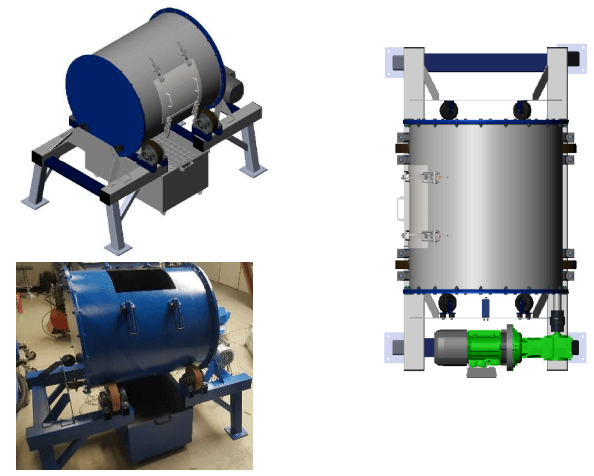

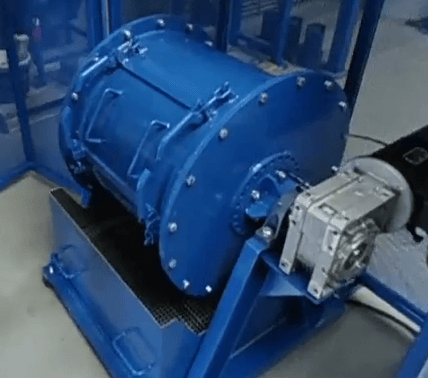

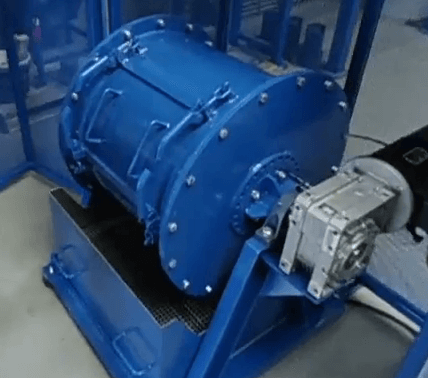

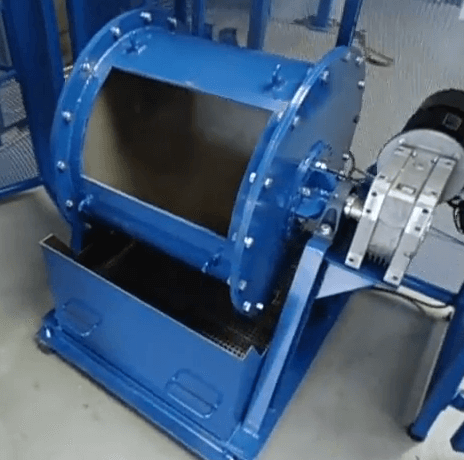

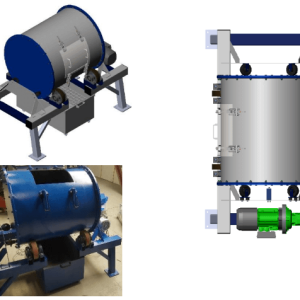

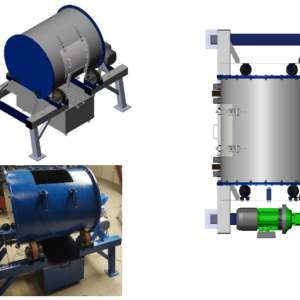

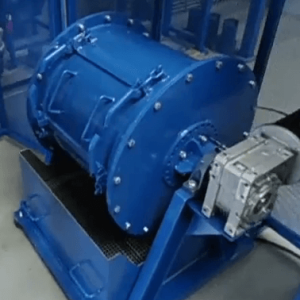

This is our largest batch ball mill. Best at dry grinding, it has a grinding chamber of either 150L or 300L (40 or 80 gallons). The 911MPELMBM-150/300 is a process and laboratory machine, which is suitable for milling and homogenizing soft, fibrous, hard, and brittle materials in the dry and wet state.

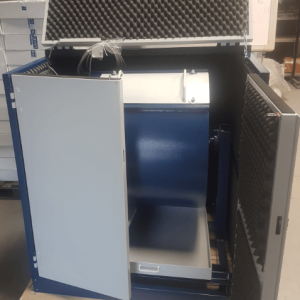

The ball/rod mill is designed to accept a ball/rod charge to 30% of the total volume. The barrel is charged with balls and sample and allowed to grind for the desired time. The milling chamber of the 911MPELMBM-150 is surrounded by a safety cabinet, with a safety locking system.