Table of Contents

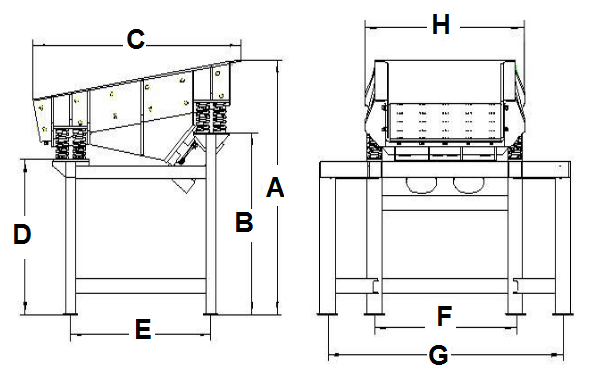

Vibratory feeders are used in gravimetric feeding systems to handle solids with particles that are loo large to be handled by screw, rotary-vane, or vertical-gate feeders, or in operations where the physical characteristics of the solid particles would be adversely affected by passage through these volumetric feeding devices. The discharge flow pattern of a vibrating feeder is extremely smooth and thus is ideal for continuous weighing in solids flow metering applications.

The vibratory feeder consists of a feed chute (which may be an open pan or closed tube) that is moved back and forth by the oscillating armature of an electromagnetic driver. The flow rate of the solids can be controlled by adjusting the current input into the electromagnetic driver of the feeder.

This input controls the pull of the electromagnet and the length of its stroke. Vibratory feeders are well suited for remote computer control in integrated material handling systems.

The vibratory feed chute can be jacketed for heating or cooling, and the tubular chutes can be made dust-tight by flexible connections at both ends. The vibratory feeders can resist flooding (liquid-like flow) and are available for capacity ranges from ounces to tons per hour.

Electric Vibrating Feeder

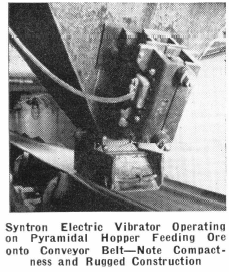

The Electric Vibratory Feeder is a vibrator that provides an extremely efficient, simple and economical solution to the problem of making the most stubborn material flow freely. No longer need there be a sticking together of wet ore in the ore bin, or the arching over and hanging up of materials in hoppers and chutes with resulting lowered operating efficiency.

The powerful vibration of the simple, electro-magnetic vibrator is controlled by a separate, wall-mounted “Controller,” which is furnished with each vibrator. The dial rheostat in the controller varies the power of vibration. By merely turning the manual dial rheostat the power of vibration can be turned down to provide the most effective vibration required for the purpose. The controller is in a separate, dust-proof housing, arranged for wall-mounting at any desirable distance away from the vibrating mechanism attached to the bin, hopper, or chute.

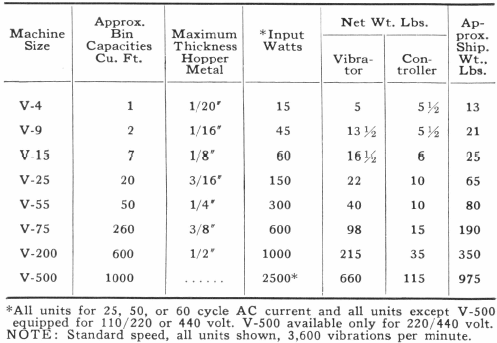

These vibrators are furnished in many different sizes. Units are available that range from those equipped to handle large tonnages in ore bins down to the small noiseless model best suited to be attached to a dry reagent feeder. Reagent feeder applications are numerous, but a well-known use is where the vibrator is utilized to keep moist lime or soda-ash stirred up and flowing evenly.

In an ore bin with a flat bottom and a center discharge, the material, especially when wet, will build up in the corners and form a dead storage space just inside the walls of the bin. One or two vibrators mounted on the outside of the ore bin (opposite to each other, when two are used), will eliminate the work that otherwise frequently has to be done by hand with a pick and shovel. Another, and possibly more important aspect, is that maximum treatment efficiency is assured by an even feed to crushers or ball mills.

This small, inexpensive unit will save man-hours, assure a smooth running mill through providing an even feed, and will pay for itself in the first few months of its operation.

These vibrators are also available at extra cost with totally-enclosed explosion-proof, or water and dust-proof cases. Also, for special jobs where danger of explosion or fire exists, a water or air-pressure vibrator can be furnished. A major advantage of these hydraulic vibrators over electric vibrators is that they can be made to run at a slow speed as well as at a high speed (2400 to 4800 vibrations per minute).

Vibrating Feeder Capacity

Electric Vibratory Feeder Capacity Formula

q = W x D x δ x v/4800, tons per hour

where q = capacity of the feeder, tph

W = tray width, in.

D = material depth, in.

δ = density of the material, lb/cu ft

v = material flow velocity, ft/min

The flow velocity depends on the method for loading the feeder—is it fed through a hopper? The velocity is also dependent on the material characteristics, size distribution and moisture content, as well as the slope of the feeder. The only way to determine the value for v is by actual observation and then the feeding rate may vary considerably.

How Feeders can improve Material Flow in Bins

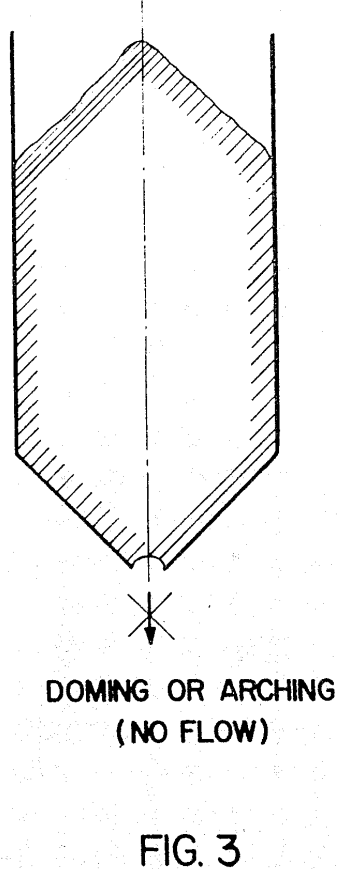

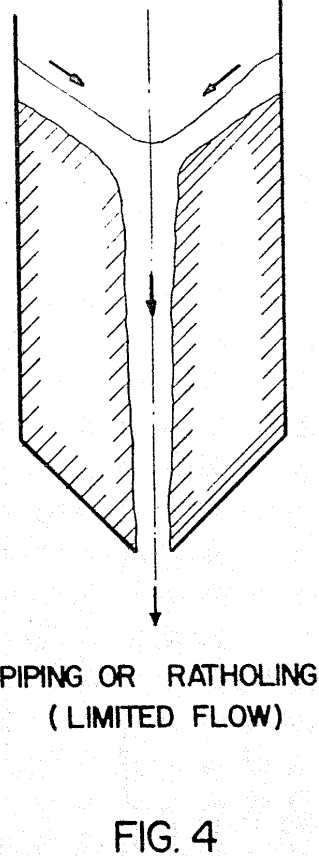

Feeders are used to provide and control the flow of bulk solids to the process from storage units, such as bins, bunkers, silos, and hoppers. In to-day’s fully instrumented process plants, it is mandatory that feeders maintain a uniform flow of material at the rate set by signals from process equipment farther downstream in the flow. Large variations in feed, due to feeder blocking, arching or ratholing in the bin, may completely defeat the purpose of such a sophisticated control system with all its planned advantages to the process.

Flow of Bulk Solids

Before proceeding to the main subject, a brief review will be given on the basic flow patterns of bulk solids.

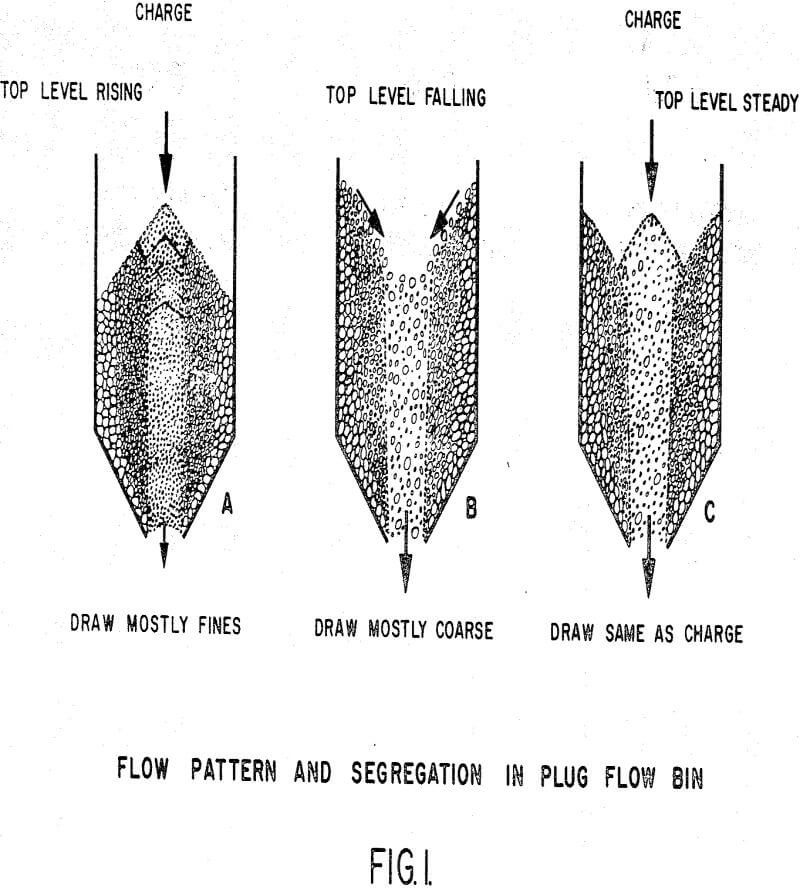

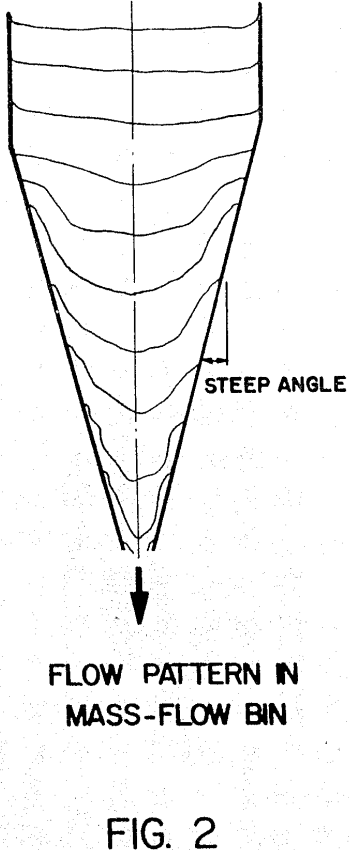

Most of the bins used in the mining and metallurgical industry to-day are of the plug flow type, as they are suited for the storage of hard, abrasive or coarse materials. Exceptions are the ore concentrate or fine powder bins which usually are of the mass flow type.

Plug flow occurs in bins or hoppers with flat sloping walls and is characterized by the flow of solids in a vertical channel extending upward from the bin outlet. Plug-flow bins are suited for solids which are free flowing, do not deteriorate with time and in which segregation is of no importance. As flow does not occur at the bin walls, this type of bin is useful for the storage of hard and abrasive materials. The drawbacks of this type of flow, however, are as follows:-

a) The live bin capacity of the bin is drastically reduced.

b) The bin is not self-cleaning and usually cannot be emptied by gravity flow.

c) Materials which deteriorate with time cannot be stored in this type of bin.

d) The flow is erratic and non-uniform, as solids flowing through a vertical channel with a constant cross section tend to form arches which collapse and compact the material below, thus causing arching again.

e) This type of flow pattern in the bin aggravates the segregation of particle sizes.

In many instances, hopper openings are large enough to prevent arching: however if the hopper is not designed for mass flow, piping or ratholing may occur. In plug flow bins, the material flows in the centre of the bin, into which the sides slough as the material is drawn from the bin. Reaching a certain level in the bin where the material has time to consolidate, sloughing will cease and a steady channel or rathole (limited flow) will form, drastically reducing the bin’s live capacity. In mass flow bins, channelling can also occur if the feeder does not draw the material uniformly across the whole area of the feed opening.

Improving Material Flow in an Existing Bin

To overcome flow problems, flow-promoting devices such as external vibrators, pneumatic air panels, air jets and vibrating internal structures are usually installed. These relatively inexpensive devices can solve the problem in marginal cases. However, where the costly complete re-design of bins or hoppers is indicated by bulk solids flow calculations, other apparently less costly ways for improvement are usually sought.

The extension of the mine workings under adjacent lakes for the reach of the recently found copper ore body, and the introduction of sand fill underground in the past years using the mill tailings, led to build-up of the moisture content of the fine ore. In the meantime, the 50% increase of daily mill output from the original 2000 to 3000 tons necessitated finer fourth stage crushing and the addition of an extra grinding mill. The fine ore actual handled to-day is a roll-crusher product of -5/32″ in size with a moisture content of 2% to 3%.

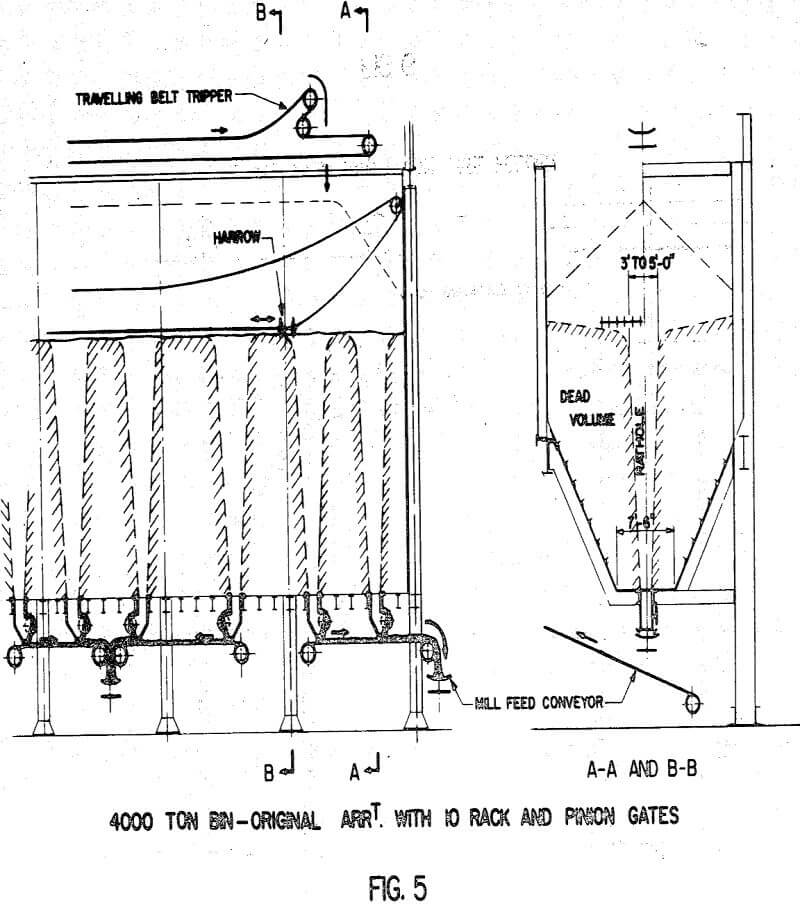

The fine ore bin, as originally conceived with its wear angles on the sloped walls, is of the plug-flow type. It performed satisfactorily in the earlier stages of operation of the plant when the material handled was coarser and lower in moisture content. With increasing ore moisture and material fineness, however, the live capacity of the fine ore bin was gradually reduced to a point where, in some instances, only channelling or ratholing occurred over the feed openings.

After visiting installations using long belt feeders, consideration was given to the use of the existing gathering conveyors as belt feeders. This scheme involved the cutting of long slots into the bin bottom above the entire length of the existing belts.

Improving Material Flow in a Flat Bottom Silo

The flow pattern in a flat bottom bin with single or multiple openings is usually of the plug-flow type. The drawbacks of this type of flow have been explained previously. It was felt, however, by the author that improvements could be made by the appropriate location of feed openings and by the use of suitable feeders. The basic idea for this improvement was initiated by the review of the results of model tests performed on flat bottom bins, which indicate a “mass flow” type of pattern at the beginning of the bin discharge. This pattern switches gradually to plug flow as the material level drops below a certain point. This partial mass flow situation can prevail only if the material handled is reasonably free-flowing, the feed openings are sufficiently closely spaced, and the material is drawn uniformly from each opening.

The example illustrated is taken from an iron ore concentrator, and shows the arrangement in which the mill feed conveyor is receiving material from the gathering belt located underneath the two silos. The fine ore handled is taconite, -5/8″ in size, and a tertiary cone crusher product with 1 to 2% moisture.

When drawn empty, the dead material left in the bin generally takes the form of a wedge-shaped hopper. However, the slope of the material should not be mistaken for the angle of repose ∝, as it is really the included half angle θe of the flow channel, which is usually much steeper due to material consolidation. Approximate expected values of θe can be calculated knowing the flow properties of the material handled.