- To participate in the 911Metallurgist Forums, be sure to JOIN & LOGIN

- Use Add New Topic to ask a New Question/Discussion about Grinding.

- OR Select a Topic that Interests you.

- Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent).

Using Add Reply allows you to Attach Images or PDF files and provide a more complete input. - Use Add Comment = to comment on someone else’s Reply in an already active Topic/Discussion.

Quantifying Grinding Efficiency (16 replies)

A metric often encountered in the hard rock business is a measure of the power consumed per unit of desired product e.g. kWh/t of -75 micron material in cyclone overflow (assumes you want to grind to 75 microns). You have to compare the specific electrical energy consumption required for the targeted milling final product particles size.

The milling efficiency defined as the ratio of theoretical work index by operating work index can also be used.

From an operations perspective would you say that energy savings from improving grinding efficiency offer the biggest cost savings to a typical mine?

This is correct as the grinding is the highest electrical energy consumer in concentration plants. The increase of grinding efficiency will represent important economy for the mine.

For many mineral processors, drying and smelting can be just as bad or worse, but grinding is always the most galling, as in 'theory', it should not be so bad! I fully agree that, kWh per tonne of -75 micron (or whatever size) is a good place to start.

Could you please provide a description of your crushing and grinding circuit, indicates particle size in each stage, tell me what type of hardness testing you have performed for your ore, what type of metals are you dealing with .

have you performed plant sampling campaigns while measuring energy consumption, do you have the grinding and comminution efficiency curves (based on size by size assay of the feed and discharge and on the energy consumption, do you have the classification efficiency curves for your screen and cyclones (if any).

First remove the water from slurries then grind the dry material; for removing water from the slurries i know a machine, equipments manufacturer if you want.

Thanks, however, the technology I am looking at needs to use wet grinding. Solids could possibly be increased, but it would still need to be in slurry form.

If the ball mills are in connection with hydrocyclones then the ball mills can't be evaluated by themselves but they need to be assessed as part of the grinding classification system.

In any case the evaluation is simple: You need to take a sample of the feed to the grinding-classification system and a sample of the discharge of the system. If cyclones are present then you need to include internal streams such as mill discharge, cyclone feed , cyclone underflow, cyclone overflow. You develop this sampling and measure the consumed energy during the sampling period.

You perform this sampling when you are using the reagent and when you are not using it, but you repeat this sampling at least 3 times per condition to discard that random results are making you to take the wrong conclusions.

You perform size analysis of the different streams and then calculate the grinding efficiency and classification efficiency. Make sure that every sampling campaign last at least 4 hours to make sure that the circuit is in steady state. The residence time in the mills is short as well in the cyclones but the steady state for a circuit is not reached in short time

in the method that I'm suggesting, you end calculating the Specific Selection Function for grinding in ton/KwH as a function of the particle size plus the grinding efficiency by each size fraction

Check any lab testwork for screen passing size. The bond work index actually changes for a specific ore depending on the product size you screen for. I.e. if you are comparing a 75micron product in the plant with a 125 micron product in the lab.

This means that if you are looking at how grinding efficiency varies at different product sizes you will need the BWi in the lab at similar passing size.

One way around this is to use the Morrell fine work index as your basis for comparison. This is an attempt to make the milling work index independent of product size. You can use the lab data from a standard bond ball mill test to calculate this alternative index.

Grinding efficiency plays an important part in calculating the work index of any Ore or Minerals. The Lab data should be precise before scaling to pilot scale and this should be repeated to come to final conclusion.Screening at 74 microns is a tedious affair and there should not be any clogging. Standard bond mill tests are the starting point.

I think the point is missed here.

One should grind to the requirements of the treatment needs of the ore in question

To overgrind costs a lot of money in maintenance, power, steelballs, liners and result n float losses.

Fine grind helps in gold recovery and most other leach plants, especially when it comes to leach mixing characteristic and viscosity which need to be looked at.

Do bottle roll tests to see at what grind you get the best recovery and float runs open and closed circuit using different grind ranges to see at what grind the float is optimized from a recovery point of view... the float will be more challenging as fine grind will liberate more minerals but risk residue losses, course grind could increase residue losses as well, so do the test work to get the optimum grind, after this you can worry about power draw, demand and sizing.

Grinding efficiency could be defined in many ways, useful consumption of energy usually being the parameter to be maximized. The Bond Work Index is a measure of theoretical power consumption to grind to a certain size while the Operating Work Index can be measured for an industrial system and reductions in Operating Work Index show improvements in efficiency. However, milling is a preparation for the downstream process and recovery losses occur in both coarse and fine size fractions so the target size range needs to be identified. Operating Work Index is not always able to account for this. I have been able to use Functional Performance Analysis to track increases in rate of production of desired product size range material during an optimization of a number of mills.

Some very interesting and informative comments from everyone, and thanks for that. We have just run some Bond Index studies and found a reduction in energy requirements with our additive and now need to consider the next step. It is evident from this discussion that we need to give this very careful consideration.

The best way is to quantify the absorbed energy per hour per tone ( Kwh/t) for a given Ore milling practice at a given predetermine hardness and comparing it to the theoretical Power consumption. Care has to be taken to ensure certain influential parameters are kept more or less constant during this survey. such parameters are mathematically represented as

Absorbed power ( Kw) =f( Mill diameter 3,RPM 1.27 ,Filling Degree, Length, pulp Sg)

Efficiency is an ambiguous word that needs to be defined for each specific case. For some people it means power to produce one t/h that's minus a certain size. For others it means actual power compared to predicted power from a Bond work index test to grind a ton to 80% minus a certain size. For others, it means ratio of right size material produced compared to total material ground. It's also affected as much by the sizing or classifying device used as by the mill itself.

Operating work indices include motor, drive and grinding mill efficiencies and inefficiencies, therefore, are not directly comparable to work indices obtained from grindability tests performed on the same mill feed, without the application of correction factors.

Mill power as measured in many plants is motor input power, that is, electrical energy going into the motor. It has to be converted to power at the mill pinionshaft. This is done by applying the motor efficiency factor (electrical and mechanical losses) to obtain motor output power. If the plant does not have the motor efficiency data, it can be obtained from the motor manufacturer. When the motor is coupled direct to the pinionshaft, motor output power is mill pinionshaft power. If a speed reducer or other drive element is used between the motor and the pinion shaft, then the efficiency of the units used must be applied to the motor output power to obtain power at the mill pinion shaft.

The grinding efficiency factors should be applied as required to place the operating work index at the same level as the results from grindability tests. The operating work index so calculated is referred to as Wi0c- This operating work index divided by the work index from the grindability test gives a treasure of grinding efficiency as a multiplier of grindability test results.

(Wioc/Wi) = Efficiency Factor........................................................(3)

The efficiency of the grinding circuit is

100(Wi/Wioc) = Grinding efficiency in percent...........................................(3A)

The multipliers for the efficiency factors can be determined from the following:

EF1 Dry grinding - for the same range of work as wet grinding, dry grinding requires 1.3 times as much power as wet grinding.

EF2 - Open Circuit Grinding - when grinding in open circuit ball mills, the amount of extra power required, compared to closed circuit ball milling, is a function of the degree of control required on the product produced. The inefficiency factors for open circuit grinding are given in Table I.

EF3 - Diameter Efficiency Factor - using the base mill diameter of 2.44 meters (8') inside liners, the diameter efficiency factor can be calculated from the following:

EF3 = (2.44/D)0.2............................................................................(4)

Table II gives a tabulation of EF3 factors for some of the more common mill diameters in both the imperial and metric measuring systems. This table shows that when the mill diameter inside liners is larger than 3.81 meters (12.5') that the diameter efficiency factor does not change and remains 0.914.

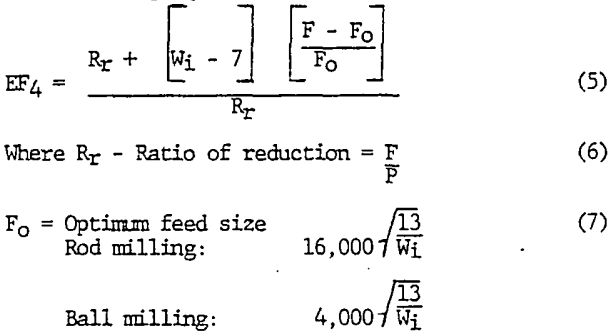

EF4 - Oversized Feed - when the grinding mill is fed a coarser than optimum feed, this factor applies to rod milling and ball milling. The most frequent use is with single stage ball milling. This is the one efficiency factor that is directly related to work index as is shown in the following equation:

When available, use the work index from a grindability test at the desired grind for Wi in equation 5. For equation 7, if available, use either the work index from an impact test or a rod mill grindability test, which ever is higher and for equation 8, use the work index from a rod mill grindability test, since these more represent the coarse faction of the feed which is the portion of the feed coarser than optimum. If not available, then use the grindability test results, available.

Without grindability test results, finding the proper work index figure to use in equation 5 is a trial and error calculation which can be programmed for a computer. Using this approach, the work index used in equation 5 should equal the Wioc obtained, after applying EF4 and all other correction factors to the work index calculated from operating data.

EF5 - Fineness of Grind Factor - this applies to fine grinding when the 80% passing size of the product (P) is finer than 75 micrometers (200 mesh). The equation to determine this is:

EF5 = P + 10.3/1.145 P..............................................................(9)

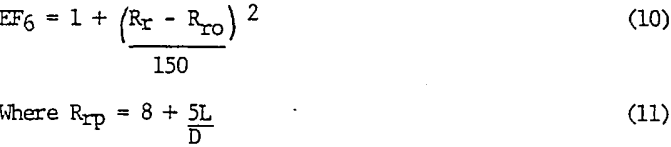

EF6 - High or Low Ratio of Reduction Rod Milling - the equation to be used, unless:

Rr = Rro ± 2

L = Rod Length

This factor generally applies to low ratios of reduction, but its application to high ratios of reduction does not always apply and should be used only if the Wioc ÷ Wi grinding efficiency factor indicates that it should be used.

EF7 - Low Ratio of Reduction Ball Mill - the need to use this factor does not occur very often as it only applies to ball milling when the Ratio of Reduction is less than 6. This shows up particularly in regrinding concentrates and tailings. The equation for this is:

EF7 = 20 (Rr - 1335) + 2.60/20 (Rr - 1.35)..........................................................(12)

EF8 - Rod Milling - a study of rod mill operations shows that rod mill performance is affected by the attention given to feeding a uniform feed size to the mill and the care given to maintaining the rod charge. This efficiency factor cannot be definitely determined. In selecting rod mills based upon power calculated from grindability tests, the following procedure has been recommended :

- When calculating rod mill power for a rod-milling-only application, use an inefficiency factor of 1.4 when the feed is to be prepared with open circuit crushing, and use 1.2 when the feed, is to be prepared with closed circuit crushing. The other milling efficiency factors also must be applied to the calculated- grinding power.

- When calculating rod mill power for a rod mill-ball mill circuit, do not allow for improvement in the ball mill performance. If the rod mill feed is produced with open circuit crushing, apply a 1.2 inefficiency factor to the power calculated for the rod milling stage only. If the rod mill feed will consistently be 80% passing ½" or finer, such as produced with closed circuit crushing, do not apply a rod mill inefficiency factor. The other milling efficiency factors also must be applied to the calculated grinding power.

While this factor is used in selecting rod mills, the inability to measure and define it accurately reduces its value and significance in calculating Wioc and therefore, should probably not be used in determining the efficiency of rod mill performance, However, knowledge of its existence can be helpful in analyzing rod mill performance.

Work indices however, do not indicate the cause for the inefficient use of grinding power, nor do they indicate the acceptability of the product produced by the grinding circuit.

Supervisory, technical and operating personnel studying the operating data and checking the operation of the plant can determine the cause for any inefficient use of power and the acceptability of the product produced.

The Bond equation utilizing work index as the measure of grindability is an accurate, reliable and readily usable method to obtain a consistent measurement of grinding circuit performance. It takes into account variations in feed size and product size with the work index calculated from the operating data reflecting either changes in the grindability or changes in efficiency. Work indices calculated from operating data, when compared to work indices obtained from Bond Grindability tests for the same mill feed, give a direct measure of grinding efficiency. The Bond Equation and the equations for the associated efficiency factors can be used by plant supervisory and technical personnel and can also be used in computer programs for reporting and/or process control. The Bond Equation and work index are useful tools in evaluating grinding circuit performance to help maximize the use of the power delivered to grinding circuits in minerals processing plants.

What is the best way of measuring and quantifying the grinding efficiency of mineral slurries? I am referring to determining energy savings by improving efficiency. Would the Bond Work Index be the best way?