- To participate in the 911Metallurgist Forums, be sure to JOIN & LOGIN

- Use Add New Topic to ask a New Question/Discussion about Pyrometallurgy and Electrometallurgy.

- OR Select a Topic that Interests you.

- Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent).

Using Add Reply allows you to Attach Images or PDF files and provide a more complete input. - Use Add Comment = to comment on someone else’s Reply in an already active Topic/Discussion.

AARL for toll elution (4 replies and 6 comments)

Thanks Kallie. Great find.

Panashe also see page 6 of https://www.scribd.com/document/247732881/Elution-and-Carbon-Reactivation-Basics

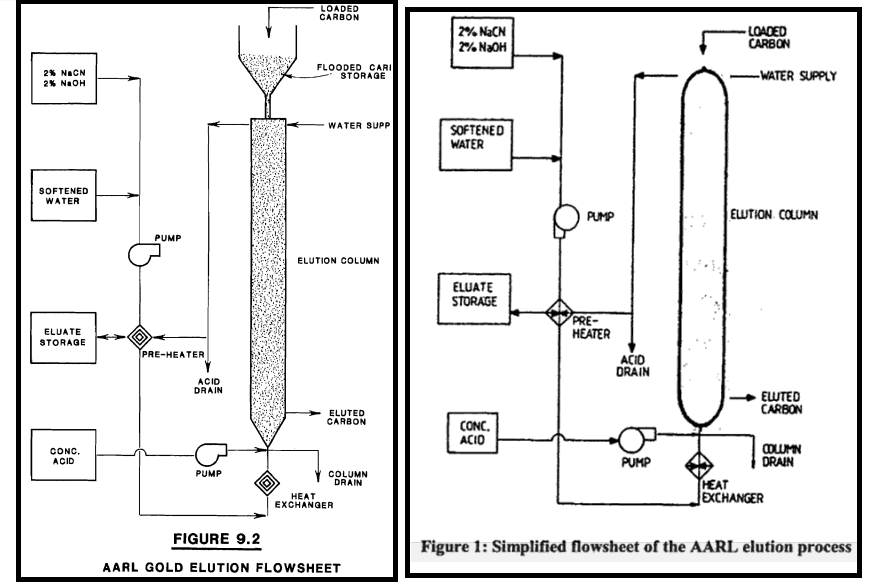

These represents a simplified flowsheet of an A.A.R.L. circuit. Loaded carbon is dispatched into the elution column from the flooded carbon storage hopper. The elution column is completely filled, and the carbon is first acid washed with one bed volume of three percent by volume hydrochloric acid (31 to 33 percent strength). This is followed by a wash of one to two bed volumes of water (the bed volume relates

to the volume of the empty column). During this period the system is raised to the required elution temperature (230'~ to 248'~ or 110 C to 120 C) and pressure (35 to 50 psig or 240 to 275 kPa), while the acid is discharged.

The acid washed carbon is now pretreated with 0.6 bed volumes of 2.0 percent NaCN + 2 percent NaOH solution. The carbon then soaks in this reagent for approximately 30 minutes.

Gold and silver are eluded by the use of water. The water flows through the carbon bed at a flow rate equivalent to two bed volumes per hour, using a total of five to six bed volumes. The water used for elution should be of a high quality, preferably containing less than 1,500 ppm TDS.

Also see this on AARL.

thank you for your valuable input greatly appreciated. For a toll a elution site located in the industrial area of small town, quality water is one of the major challenges. i was hoping to use davco to improve on the quality of water and to precipitate out cations. Would you happen to know of other methods that could be worth considering?

I would not go for the AARL just get bigger Zadra to treat more tons. Yours seems very small? max 400kg.

It is a baby. You should be able to do one elution every 24 to 28 hrs if conditions is good.

The average quantity range for loaded carbon is about 250 to 350 kgs carbon. i was hopping to provide a service that has all the advantages of the AARL circuit.

What do you mean the avg quantity loaded carbon is 250 to 350kg.??there is very big plants running on the mines taking up to 20 ton

the plant will be small scale treating carbon quantities in the range 250 to 300 kg

for toll elution, AARL is rather over the top. The cost of procuring one is astronomical.The operating parameters are way too sensitive. In Zimbabwe, i only know of Freda Rebecca and Renco which have AARL. The rest just have the pressurized Zadra or the PG boiler I'm talking of mines that are producing +/-40 kg per month. Don't give yourself a headache, scale up the size of the boiler and mind you the AARL can take more than 24 hrs to elute if your burner ain't right.

Homestake Technical Services in Kwekwe or Wayne Elution in Vainona can make you a 1 ton pressurized plant for 18-22k in a month.

For water treatment, you can use cat-ionic resins in columns to soften your water. Use brine (NaCL solution) for flushing into your water softener plant. The ultimatum goal is to reduce as much calcium and magnesium ions in water.

My Company is involved in toll elution using the pressurized Zadra (350-400kg carbon load), we are now considering using an AARL elution for toll carbon desorption as an upgrade from the pressurized Zadra and the Peter Goossen plants are there any possible challenges for treating different carbon types using the AARL? and Any information on direct comparison of operating costs would be of great help.