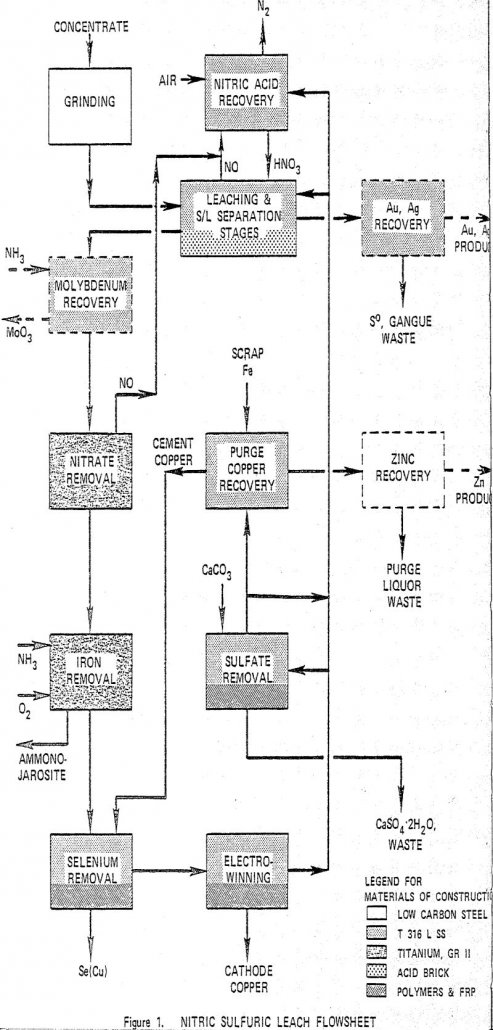

Nitric Sulfuric Leach of Copper Concentrate

Copper is leached in a staged reactor system utilizing nitric and sulfuric acids at 105°C. Iron is removed from the pregnant liquor as a jarosite and cathode copper is electrowon directly from the purified pregnant liquor. The spent electrolyte is recycled. Nitrogen oxides evolved from the leach are reconverted to nitric acid and are also […]

Mining Project Financing

In the recent past, there have been numerous projections of the capital requirements for additional mine and processing capacities required to meet projected non-Communist World demand for minerals during the next 15 years. A consensus judgment would place this currently at $14 billion per year, with the largest expenditures required for increases in aluminum and […]

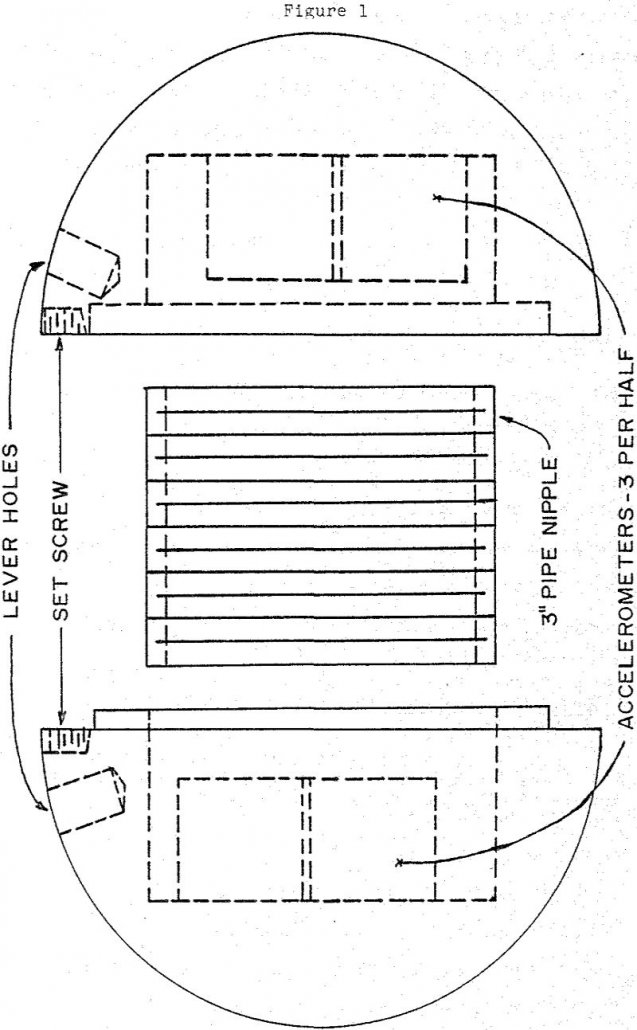

How to Measure the Impact Forces in Ball Mills

Of many physical parameters critical to design of grinding processes, impact of grinding media is among the most difficult to measure or predict. Yet impact of falling grinding balls, pebbles, or rods accomplishes the fine grinding essential to metallurgical recovery of most important minerals. Unfortunately, the same impacts that break ore fragments deform or crack […]

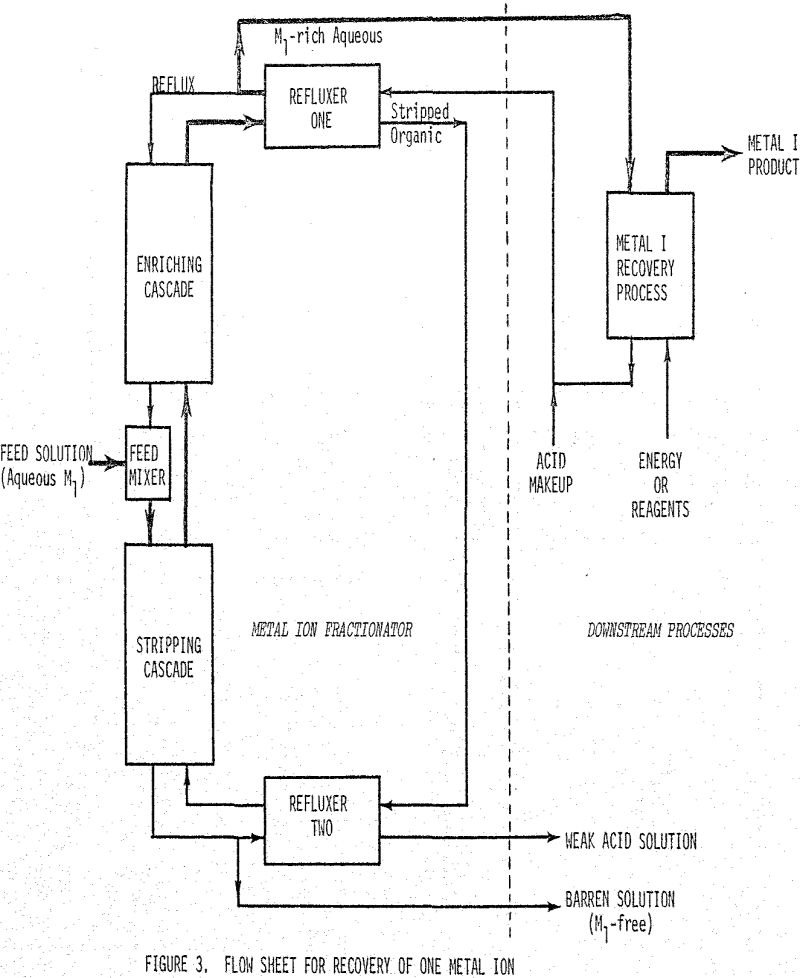

Liquid Ion Exchange Fractionation of Metal Ions

There are two basic problems when one attempts to separate a solution of metal ions utilizing a chelation-solvent extraction cascade (commonly called liquid ion exchange). First, it is impossible to produce any great degree of separation unless the separation factor (also called selectivity, which is the ratio of the distribution coefficients) is very large. Second, […]

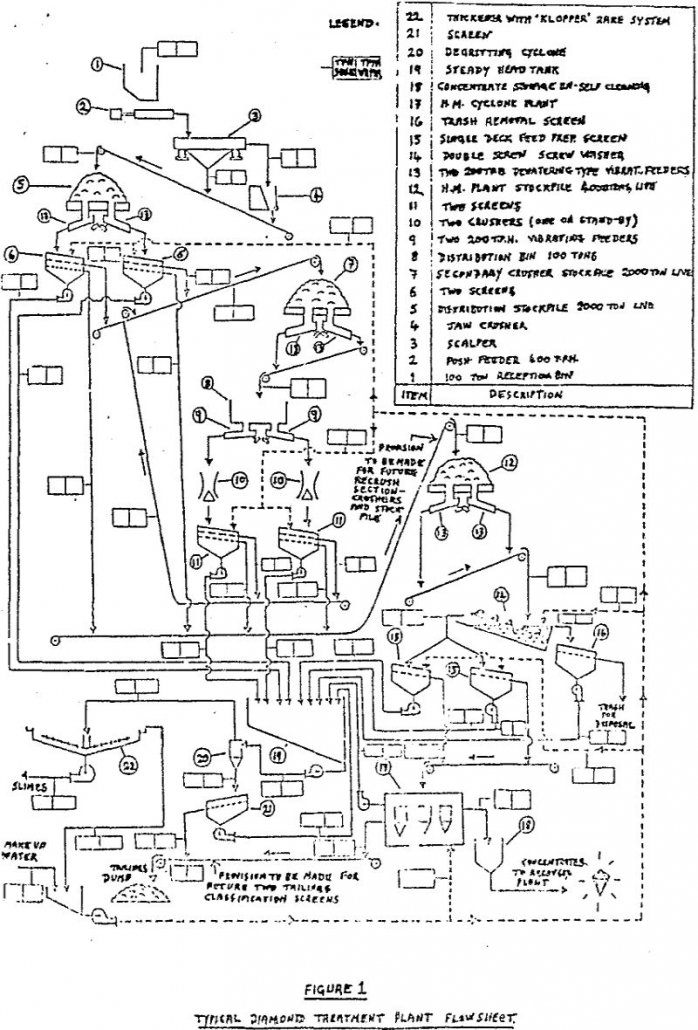

Process Plant Design

The radial system simplifies and improves control and supervision to a very considerable extent and can lead to a form of continuous plant operation with the separate sectors shutting down in succession for necessary maintenance while maintaining the overall plant operation. Radial Layout for Increased Treatment-Plant Productivity A great deal of time and trouble is […]

Launder Design Procedure

The design of slurry launders has usually been based on strictly empirical concepts. An examination of the most common procedures reveals that they do not account for many of the variables that are recognized as significant for slurry transport. These may include flow rate, volume concentration of solids, solids specific gravity, solids size distribution, particle […]

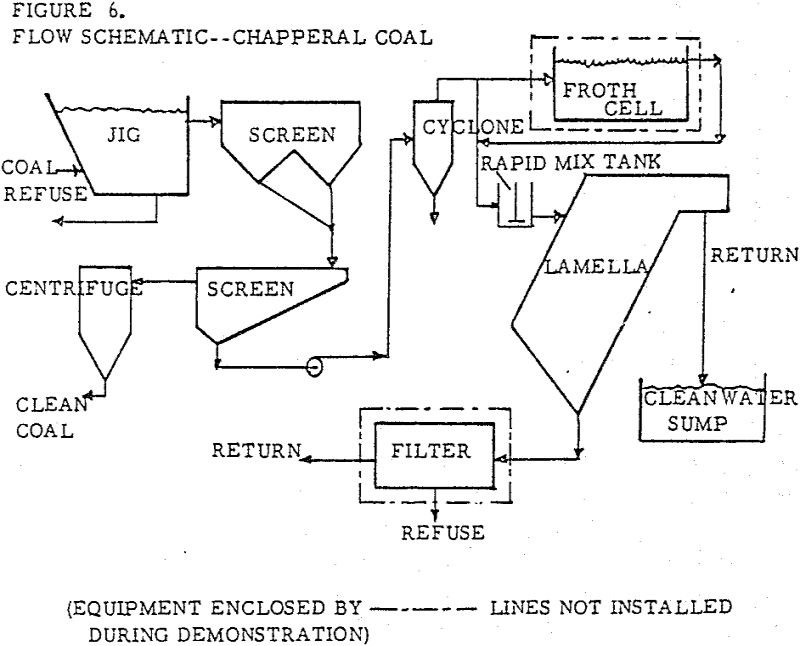

Lamella Thickeners

Stringent environmental regulations, which have limited the use of sludge ponds, coupled with the economic incentive to clean more coal or to add fine coal cleaning additions to existing preparation plants have increased the use of static thickeners in preparation plants. The Lamella Gravity Settler, sometimes designated Lamella Thickener, is a shallow depth sedimentation device […]

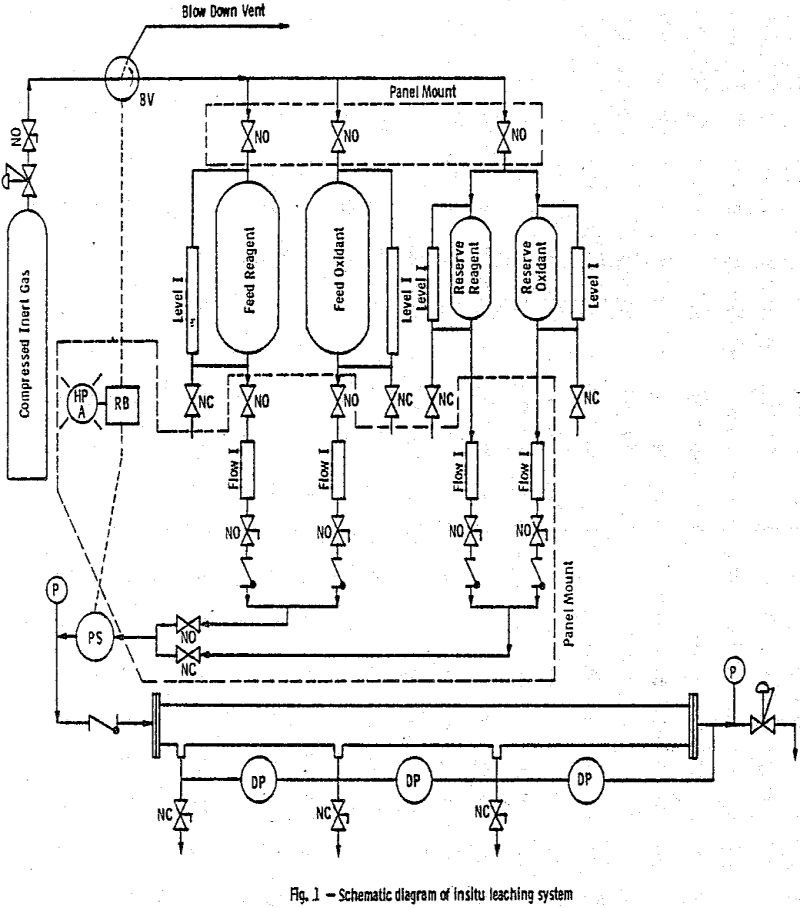

In-Situ Leaching Simulation – Uranium Ores

A laboratory method for the simulation of in-situ leaching of uranium was developed under contract to the Interior Department’s Bureau of Mines. Simulation tests using sulfuric acid, ammonium bicarbonate and sodium carbonate as reagents, and hydrogen peroxide as oxidant were carried out with representative ores from Texas and Wyoming. The tests not only yielded recovery […]

In-Situ Leaching & Borehole Mining

Terms such as in situ mining, in situ leaching, solution mining, borehole mining, and slurry mining have been used in different ways to describe a wide range of mining operations where a commodity is usually extracted remotely by activities that are conducted from the surface. As used in this publication, in situ mining is a […]

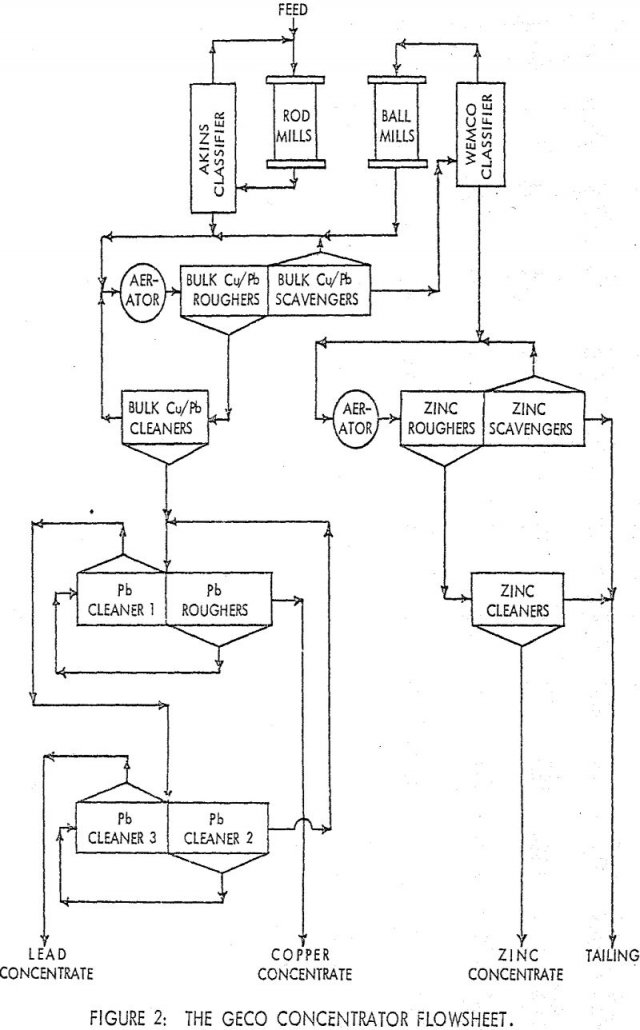

Copper Lead Separation with Activated Carbon

In many multiple-sulphide ore flotation processes, it is desirable to concentrate each of the various valuable minerals into separate products. Although there are a variety of techniques and chemicals which can be employed to produce efficient separation, two basic types of flotation circuits are used: The Differential Flotation Circuit and the Bulk/Selective Flotation Circuit. Geco […]