Screw Crusher

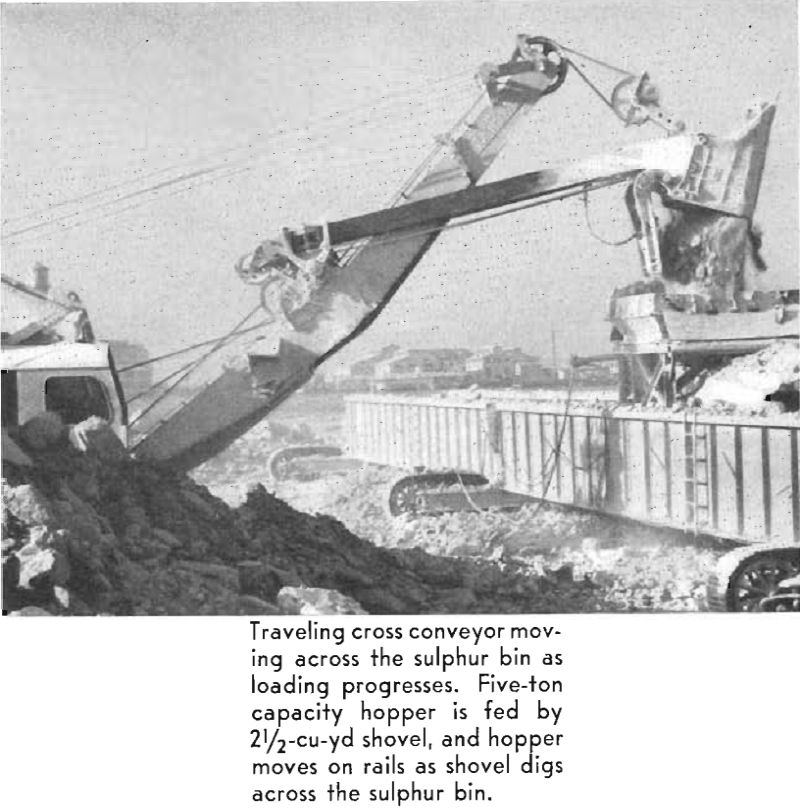

The Freeport Sulphur Co. built a portable screw crusher in 1944 that solved a problem that none of the crusher manufacturing companies contacted were able to do. Two of these crushers have now been in service for 6 years, giving satisfactory service in handling a million tons per year, and having a capacity of over […]

Copper Gold Sulfide Ore – Flotation & Cyanidation Tests

Grinding the ore to minus 100-mesh gave satisfactory liberation of the minerals. Standard flotation procedure with potassium ethyl xanthate, cresylic acid, and lime produced good-grade copper concentrates with over 85 percent recovery of copper and about 60 percent recoveries of gold and silver. This stop was employed in two methods of treatment developed during laboratory testing. […]

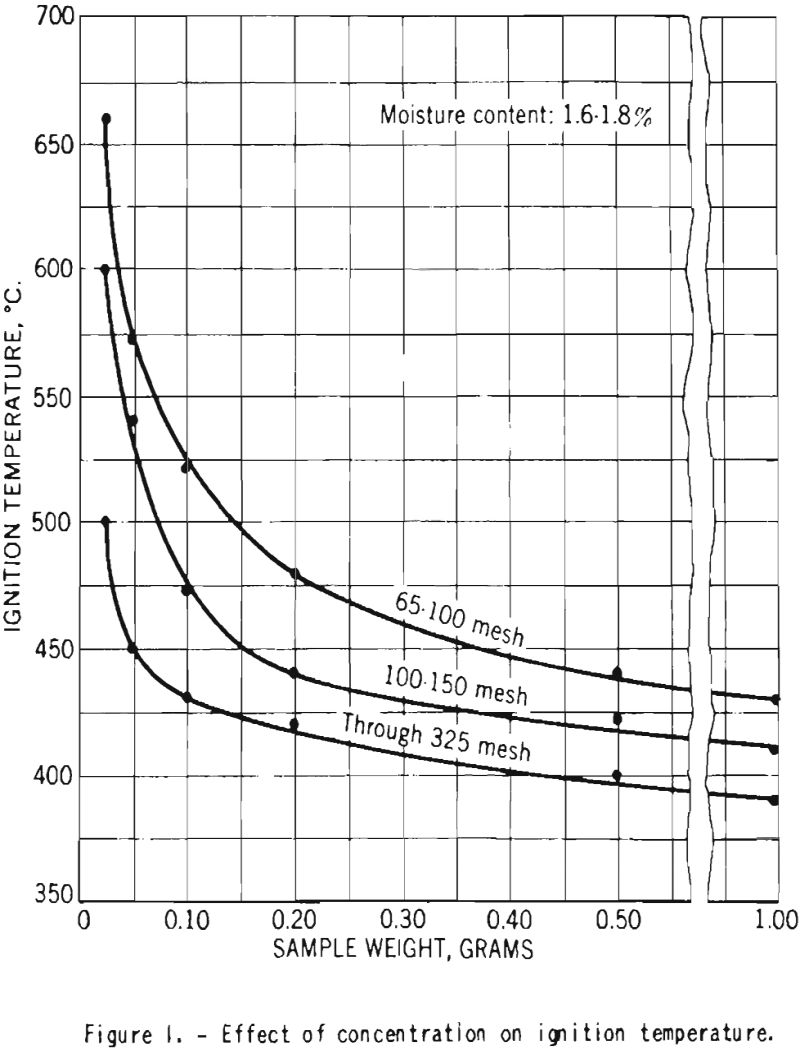

Cornstarch Explosibility

Laboratory experiments were conducted with cornstarch to study the effects of duet concentration, moisture, particle size, treatment with oil, and admixture of calcium carbonate on the dust-explosion hazard. One series of tests were made on five size fractions of starch and on samples with four different moisture contents, all prepared from a single batch. Within […]

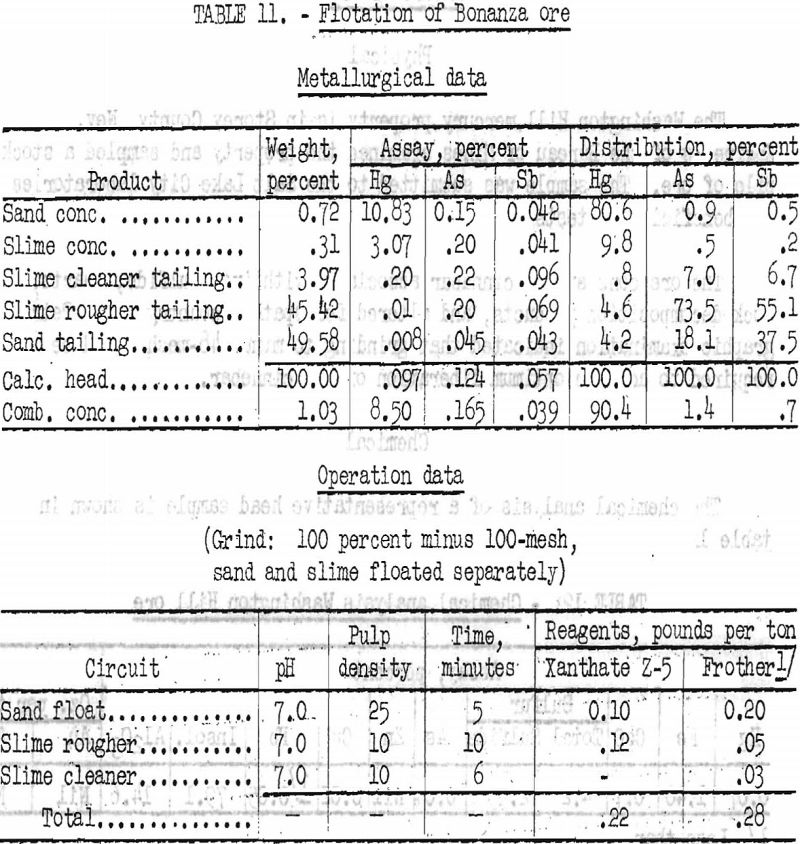

How to Concentrate Mercury

Most mercury ores are directly roasted or retorted for recovery of metallic mercury without preliminary concentration. Recoveries are high, often approaching 100 percent; the cost is nominal. The tenor of domestic mercury ores, however, has been dropping steadily, so that the estimated average heads are now about 0.35 percent Hg or 7 pounds per ton […]

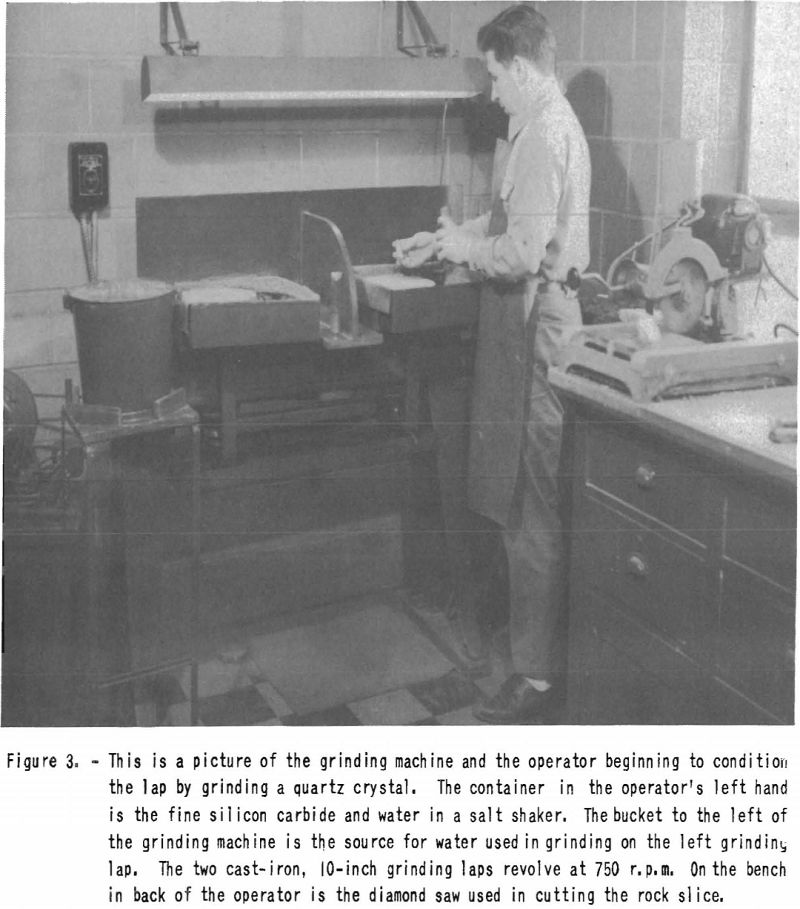

How to Prepare Thin Rock Sections

In this recommended method of preparing a thin section the operator begins by obtaining a rock slice approximately 1 inch in diameter and 1/8 inch thick. The rock slice is ground on the coarse and fine grinding laps until a flat surface without visible pits is produced on one side. An important step in the […]

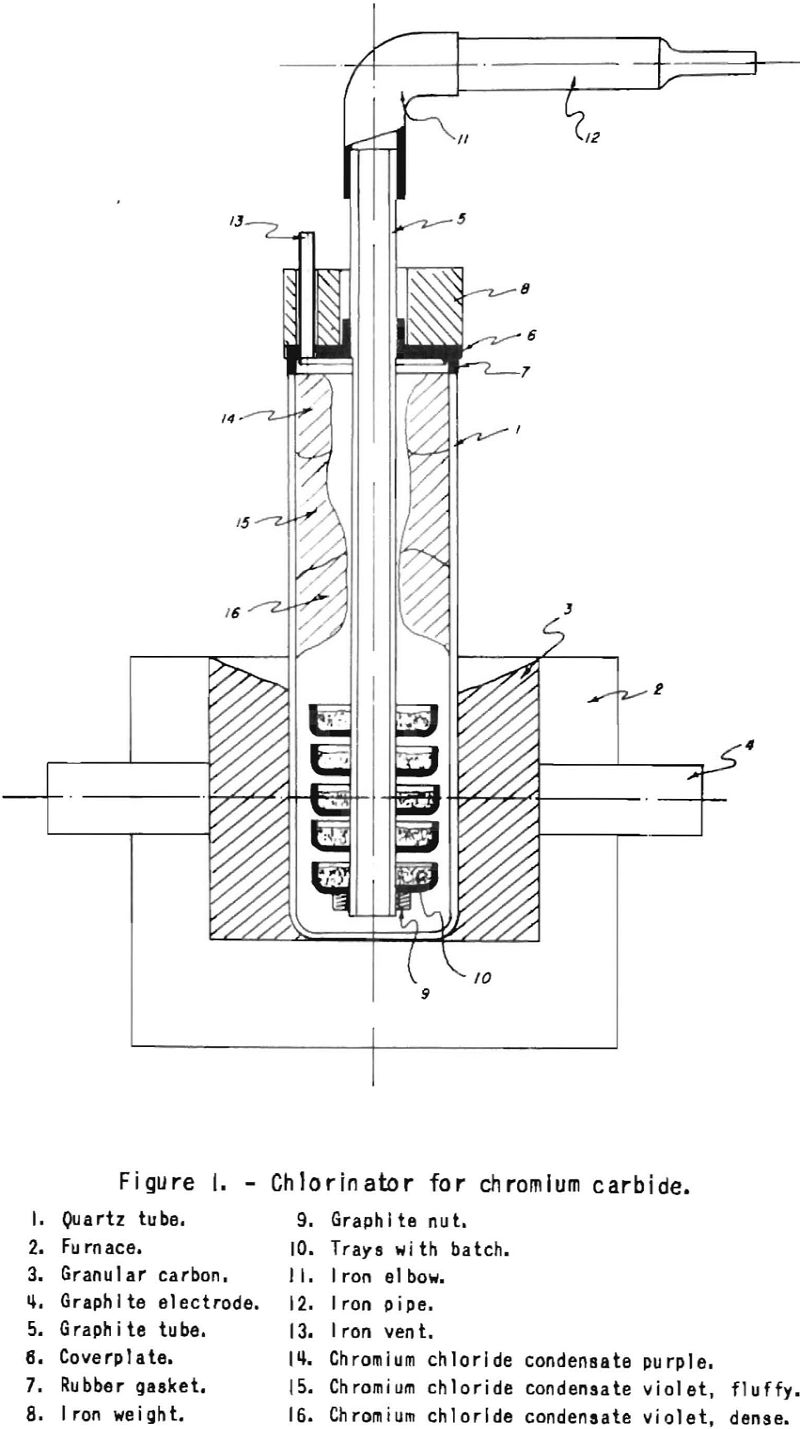

How to Make Chromium Metal – Metallurgy

Aluminothermic or silicothermic processes used for the metallurgical production of chromium metal from chromium oxide yield a metal that may contain more than 99 percent chromium. A metal of this purity apparently meets all the requirements of the alloy industry, but the price is about three times that of chromium in the form of low-carbon […]

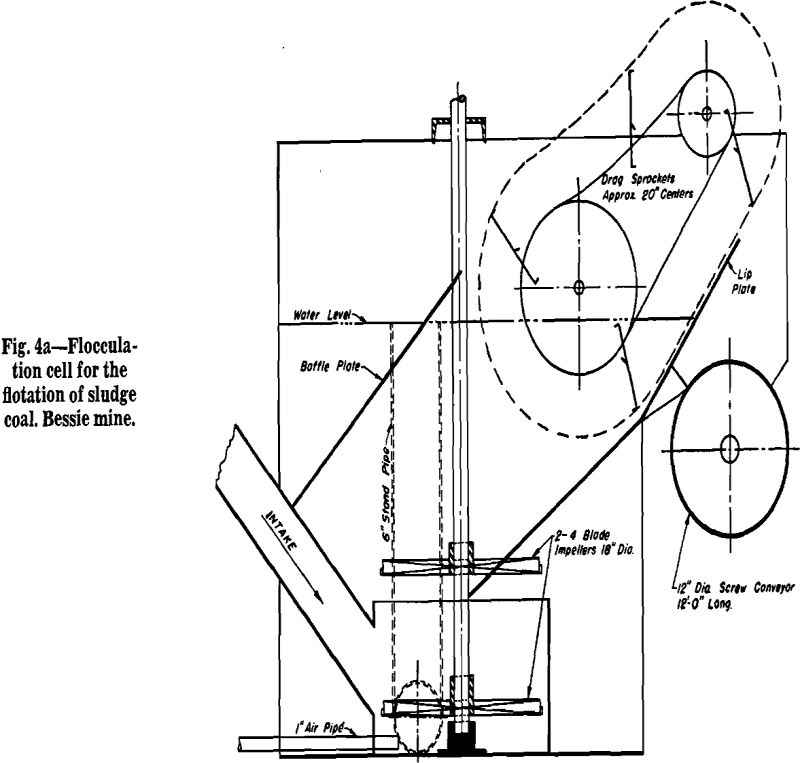

Kerosine Flotation

In cleaning coal it has long been recognized that methods which give excellent results for the coarser sizes may give poor or even no cleaning for the finer sizes. Effective cleaning of the fines, therefore, is usually a separate and distinct problem. For many years the problem of fines was considered of relatively minor importance. […]

Cadmium Recovery from Lead

Greenockite is the only known cadmium mineral of importance. It occurs rather universally, in minor concentrations, as a secondary mineral in sphalerite deposits. The world’s cadmium output is obtained through the processing of metallurgical by-products, largely from the treatment of residues from electrolytic zinc, retort zinc and lithopone plants. These sources are supplemented by the […]

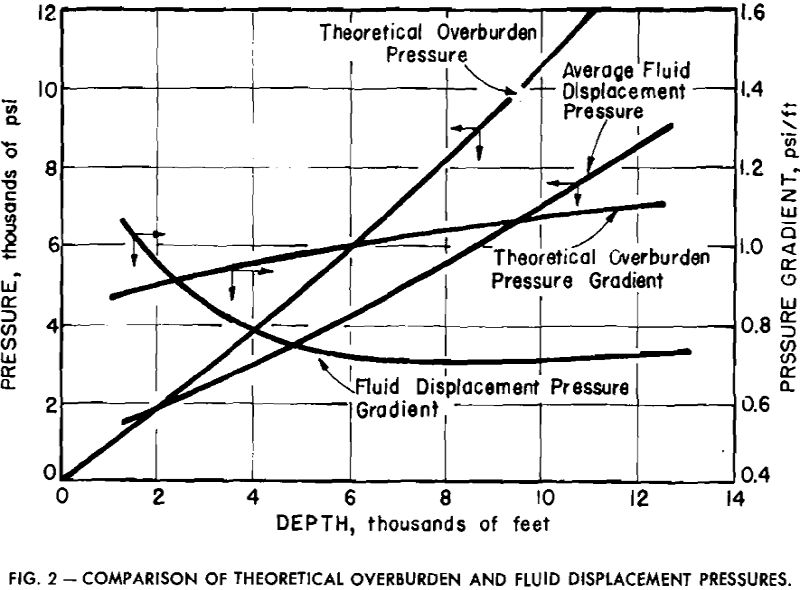

Squeeze Cementing

Laboratory and field testing of various squeeze cementing techniques and materials revealed that many improvements could be made in squeeze cementing operations. The use of a slow-pumping squeeze cementing procedure permitted the control of the quantity of cement displaced into a formation and aided in obtaining a high final squeeze pressure. Field testing indicated the […]

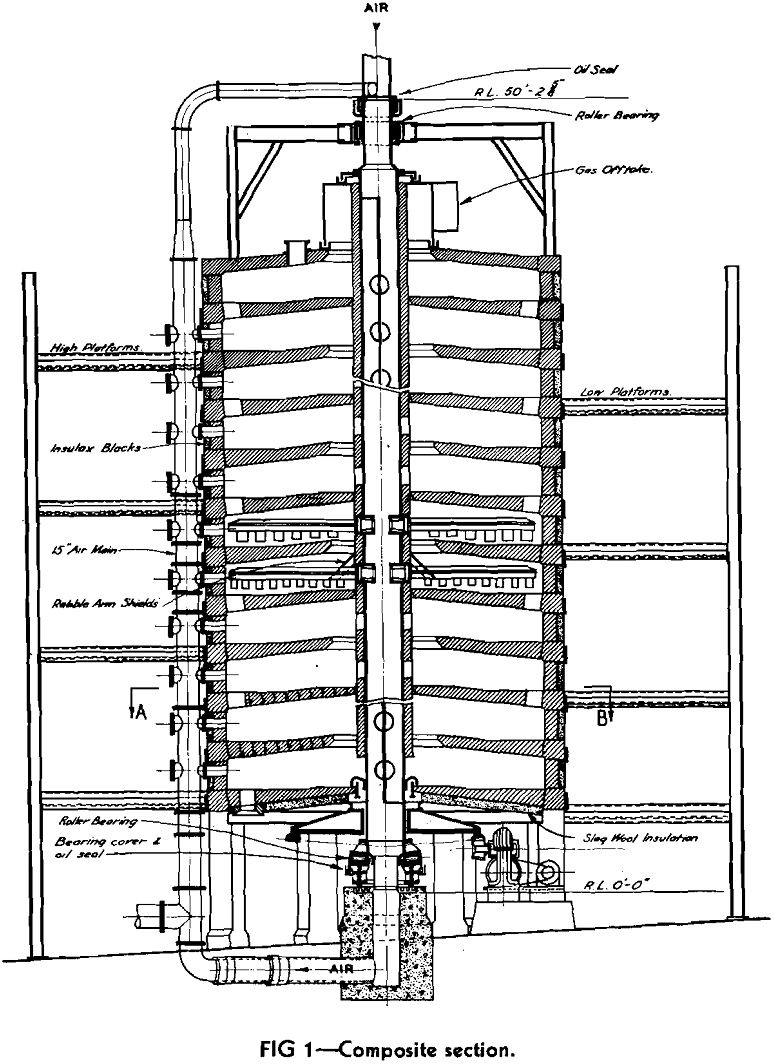

Autogenous Roasting of Low Grade Zinc

The operations of the Electrolytic Zinc Co. of Australasia Ltd. involve the preliminary roasting of zinc concentrate from Broken Hill, New South Wales, at a number of acid-making centers on the Australian mainland. The partially roasted material is shipped to the Tasmanian plant where it was formerly re-roasted prior to leaching, but this practice was […]