Conveyor Idlers Operating & Maintenance

Depending on the source of reference used, belts for handling bulk material underground came into being between 1900 and 1920, while strip mining appeared in the thirties. The conveyor belt speeds in that era were in the 300 fpm to 500 fpm range. Belt speeds of 600-700 fpm were in vogue in the fifties, and […]

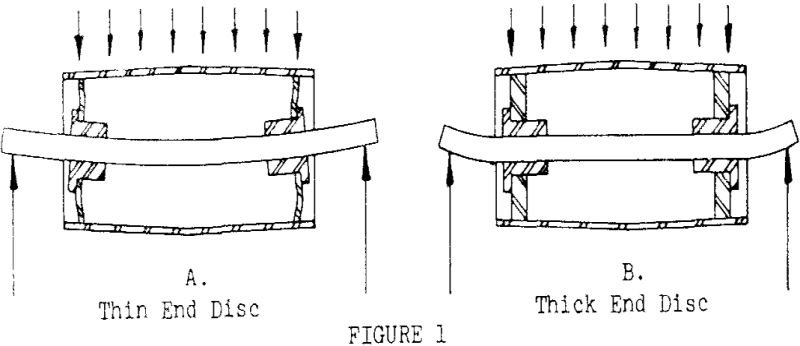

Conveyor Belt Pulleys Design Features

In belt conveyor application, a pulley’s purpose is primarily three-fold, 1) support the belt in directional changes, as designed in the conveyor, 2) transmit driving power to the belt, and 3) guide or train the belt. The drive pulley imparts the driving force to the belt and may be located at the head or discharge […]

Conveyor Belt Drive Selection

The drive selected for any piece of machinery must adequately satisfy the application requirements both during the starting interval and at running conditions. All loading possibilities of the drive must be known and allowances made for any adverse limiting conditions such as extreme cold, or perhaps an intermittent excessive loading situation etc. Characteristics of the […]

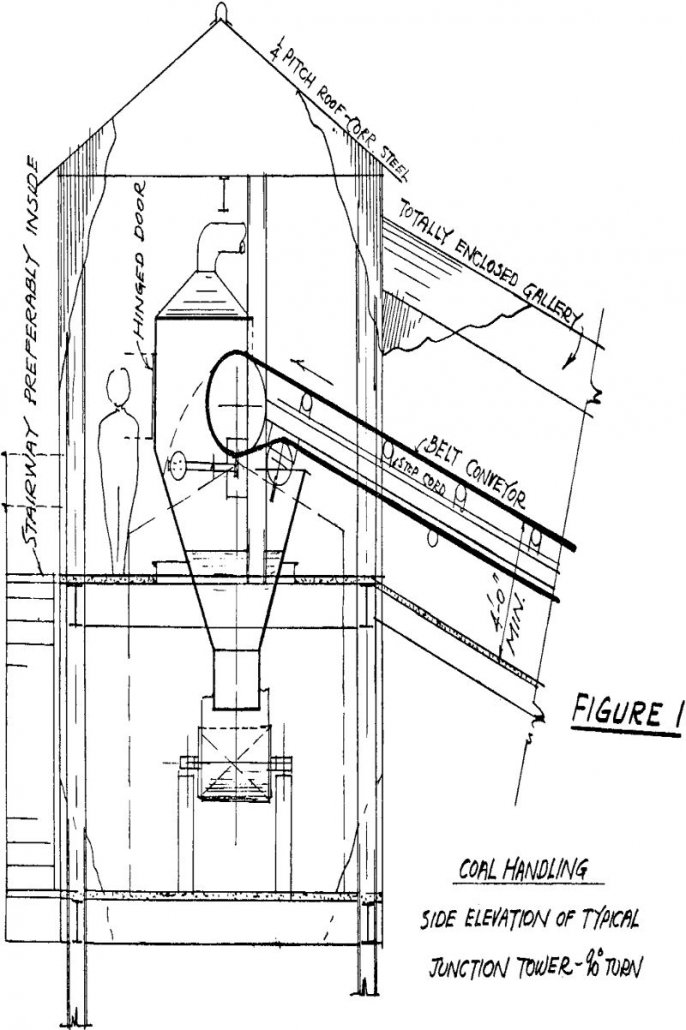

Belt Conveyor Transfer Points

Belt conveyors have proven themselves for many years as a dependable and low cost method of handling bulk materials at high flow rates. The success of a belt conveyor system greatly depends on the initial loading of the material on the belt. If the material is loaded on the belt at the center, at approximately […]

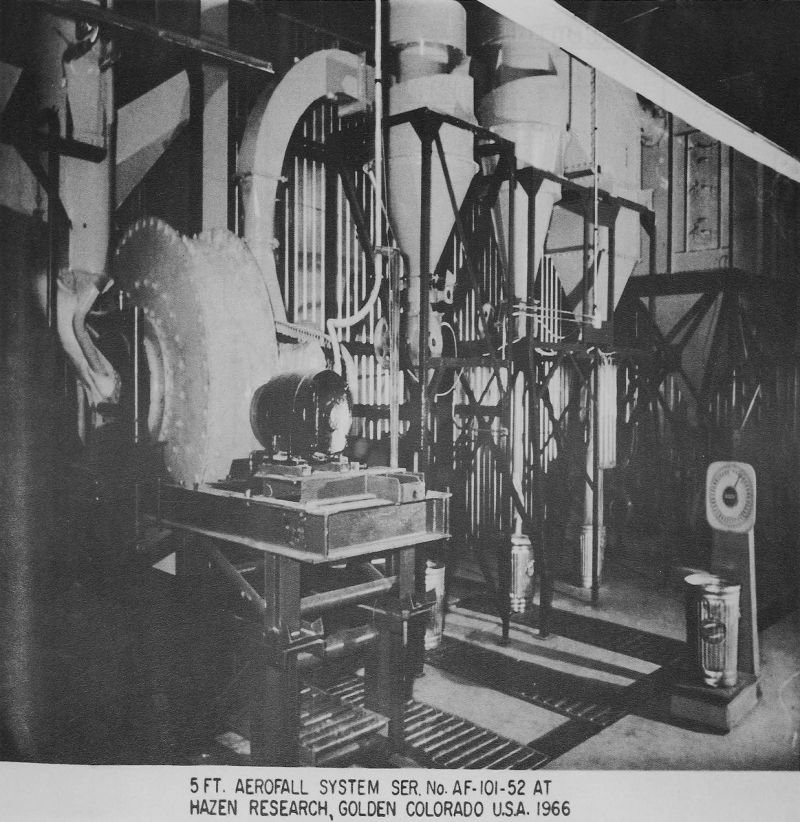

Aerofall Grinding System

In any treatment process that requires a coarse feed material to be reduced to a fine size by crushing and/or grinding it must be determined whether a wet or dry comminution system should be utilized. All factors must be evaluated in reaching the decision. Among these factors are: Ecology and Plant Environment Operating Costs The […]

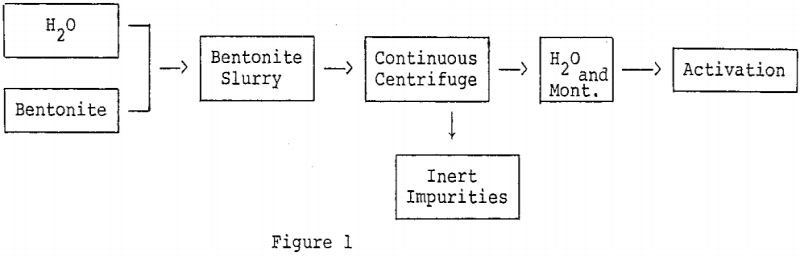

Activated Bleaching Clay

Activated bleaching clays, so called because of their ability to remove color bodies from bleach fats and oils, are produced from clays of bentonitic origin. Activation is achieved by subjecting these clays to physical or chemical alteration to increase selective sorption capacities. Bentonitic clays which are suitable for production of activated bleaching clays contain the […]